Nano fibre facial mask containing opal shale and preparation method thereof

A technology of opal shale and nanofiber, applied in the direction of medical preparations containing active ingredients, fiber treatment, skin care preparations, etc., can solve the problems of insufficient cleaning power of cleansing masks, strong skin irritation, and inconvenient cleaning. Achieve the effect of inhibiting the formation of skin melanin, preventing skin dryness, and not easy to lose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

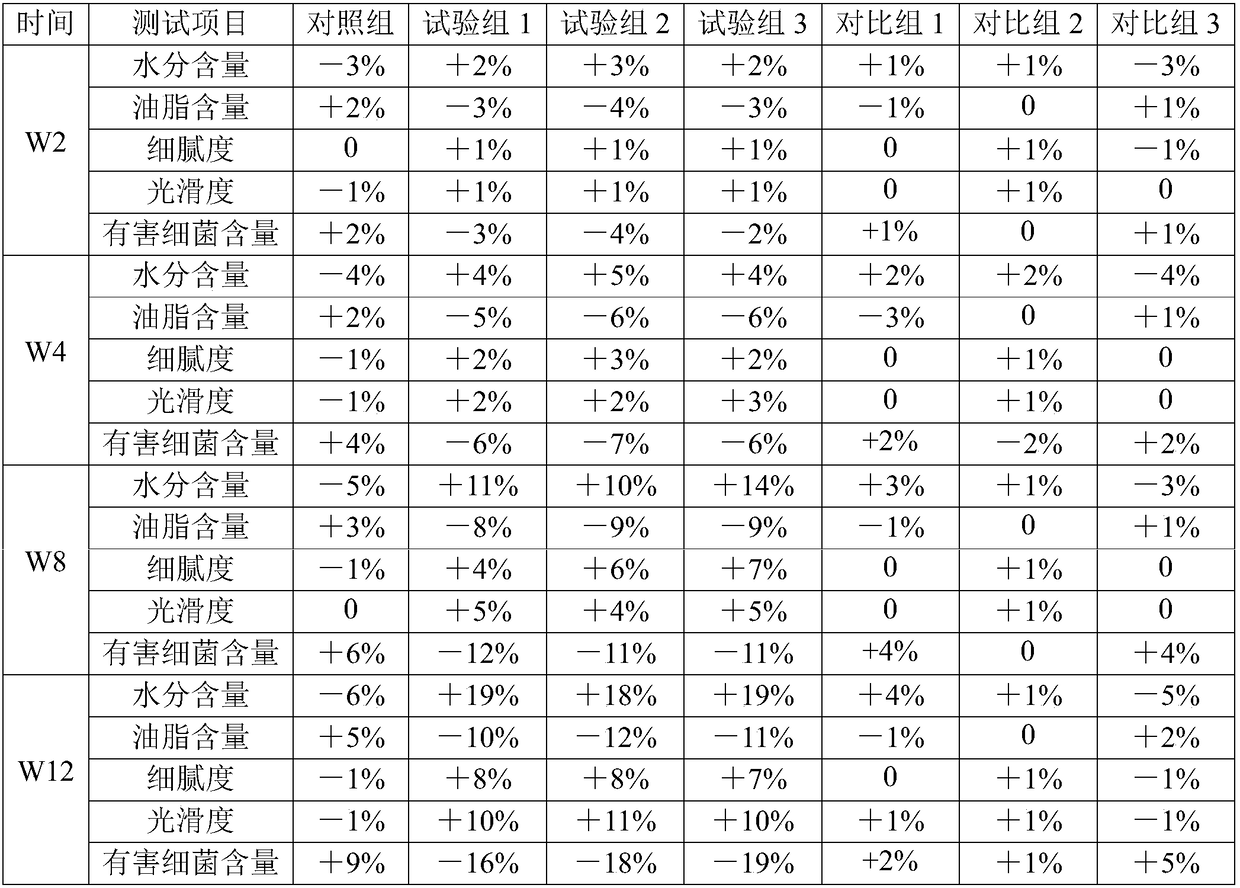

Examples

Embodiment 1

[0025] A nanofiber mask containing opal shale, made of the following raw materials in mass fractions: polyvinyl alcohol 12%, polyethylene glycol 1%, sericin 25%, opal shale 0.02%, and the balance is deionized water.

[0026] Further, the polyvinyl alcohol is PVA1797 type, and the degree of alcoholysis is 96.0%-98.0%.

[0027] Further, the molecular weight of the polyethylene glycol is 10000.

[0028] A preparation method of a nanofiber mask containing opal shale, comprising the following steps:

[0029] Step 1. Preparation of polyvinyl alcohol, polyethylene glycol, and sericin blend solution: Dissolve polyvinyl alcohol and polyethylene glycol in distilled water, stir magnetically at 80±5°C for more than 8 hours, prepare a solution, and then Mix the two solutions in proportion, cool, add sericin, dissolve in a water bath at 50-60°C for 4 hours, and cool to obtain a blend solution of polyvinyl alcohol, polyethylene glycol, and sericin;

[0030] Step 2. Preparation of the elec...

Embodiment 2

[0034] A nanofiber mask containing opal shale, made of the following raw materials in mass fractions: polyvinyl alcohol 8%, polyethylene glycol 2%, sericin 30%, opal shale 0.06%, and the balance is deionized water.

[0035] Further, the polyvinyl alcohol is PVA1797 type, and the degree of alcoholysis is 96.0%-98.0%.

[0036] Further, the molecular weight of the polyethylene glycol is 4000.

[0037] A preparation method of a nanofiber mask containing opal shale, comprising the following steps:

[0038] Step 1. Preparation of polyvinyl alcohol, polyethylene glycol, and sericin blend solution: Dissolve polyvinyl alcohol and polyethylene glycol in distilled water, stir magnetically at 80±5°C for more than 8 hours, prepare a solution, and then Mix the two solutions in proportion, cool, add sericin, dissolve in a water bath at 50-60°C for 4 hours, and cool to obtain a blend solution of polyvinyl alcohol, polyethylene glycol, and sericin;

[0039] Step 2. Preparation of electrospi...

Embodiment 3

[0043] A nanofiber mask containing opal shale, made of the following raw materials in mass fractions: polyvinyl alcohol 4%, polyethylene glycol 10%, sericin 13%, opal shale 0.8%, and the balance is deionized water.

[0044] Further, the polyvinyl alcohol is PVA1797 type, and the degree of alcoholysis is 96.0%-98.0%.

[0045] Further, the molecular weight of the polyethylene glycol is 2000.

[0046] A preparation method of a nanofiber mask containing opal shale, comprising the following steps:

[0047] Step 1. Preparation of polyvinyl alcohol, polyethylene glycol, and sericin blend solution: Dissolve polyvinyl alcohol and polyethylene glycol in distilled water, stir magnetically at 80±5°C for more than 8 hours, prepare a solution, and then Mix the two solutions in proportion, cool, add sericin, dissolve in a water bath at 50-60°C for 4 hours, and cool to obtain a blend solution of polyvinyl alcohol, polyethylene glycol, and sericin;

[0048] Step 2. Preparation of electrospinn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com