Propylene epoxidation catalyst in-situ modification method

An in-situ modification and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of slow activation of propylene epoxidation catalysts, poor PO selectivity, and many by-products. Achieve the effects of shortening the unstable period of driving, improving selectivity, activity and product selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The catalyst containing Ti-MWW molecular sieve is loaded in the reactor, and modified in situ in the reactor. Carry out the following modification treatments in turn: 1) Nitrogen purging for 30min, volumetric space velocity is 80h -1 , stamped to 2.5MPa; 2) 3wt% dilute hydrogen peroxide rinse for 12h, dilute hydrogen peroxide space velocity is 5h -1 , temperature 60°C; 3) Switch to methanol and aqueous solution containing ammonia for 6 hours, the ammonia concentration is 1.0mmol / L, the water content is 1wt%, and the mass space velocity of the mixed solution is 5h -1 ; 4) Acetonitrile and hydrogen peroxide aqueous solution were washed for 2h, the hydrogen peroxide content in the mixed solution was 10wt%, and the mass space velocity was 3.0h -1 ;.

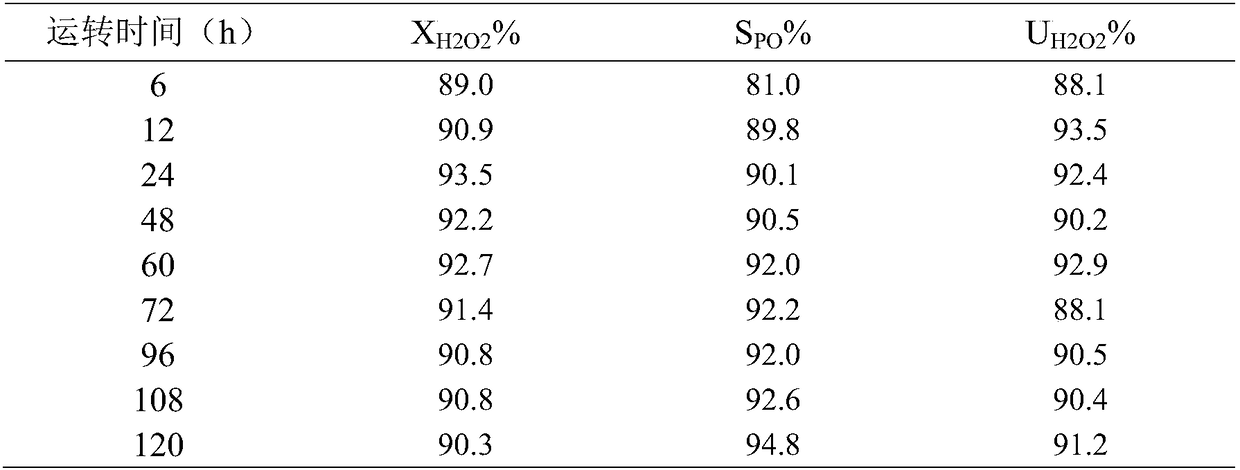

[0039] After the modification is completed, adjust the reaction temperature to 35°C, switch the reaction raw materials, and see the following table for the evaluation results of propylene epoxidation reaction:

[0040]

Embodiment 2

[0042] The catalyst containing TS-1 molecular sieve is packed in the reactor and modified in situ in the reactor. Carry out the following modification treatments in turn: 1) Nitrogen purging for 30min, volumetric space velocity is 100h -1 , punched to 3.0MPa; 2) Rinse with dilute hydrogen peroxide containing 5wt% for 24 hours, and the space velocity of dilute hydrogen peroxide is 5 hours -1 ; 3) Switch to methanol and aqueous solution containing ammonium fluoride for 10h modification, the ammonium fluoride concentration is 3.0mmol / L, the water content is 3wt%, and the mass space velocity of the mixed solution is 8.0h -1 ; 4) rinse with methanol and hydrogen peroxide mixed aqueous solution for 5h, the hydrogen peroxide content is 15wt%, and the mass space velocity is 3.0h -1 ; The modification was carried out at 80°C.

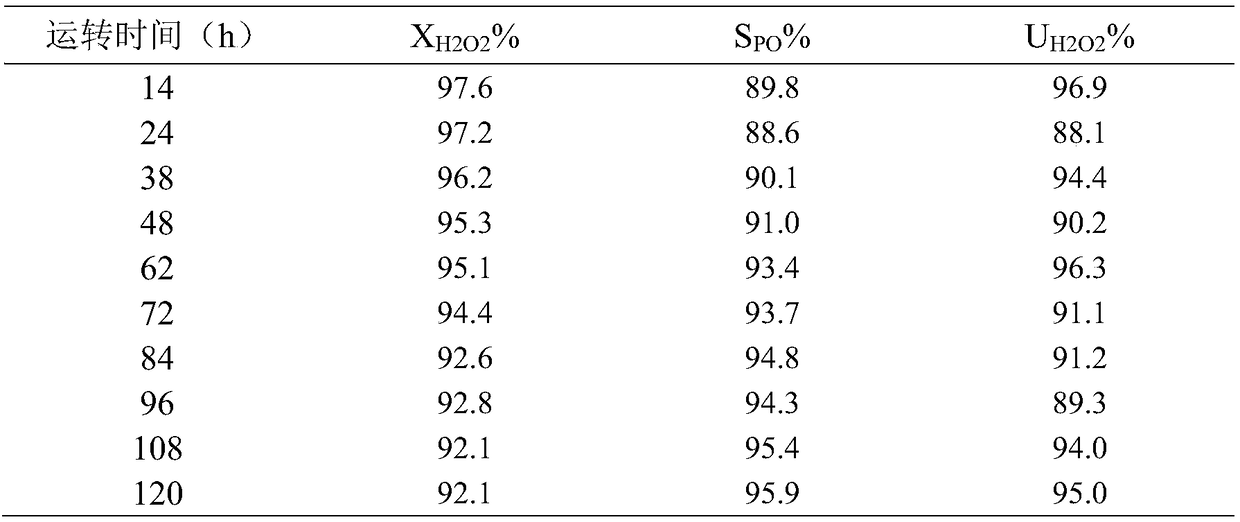

[0043] After the modification is completed, adjust the reaction temperature to 35°C, switch the reaction raw materials, and see the following table for the ev...

Embodiment 3

[0046] The catalyst containing TS-1 molecular sieve is packed in the reactor and modified in situ in the reactor. Carry out the following modification treatments in turn: 1) Nitrogen purging for 30min, volumetric space velocity is 100h -1 , punched to 3.0MPa; 2) containing 5wt% peroxyformic acid aqueous solution for 24h, the space velocity of peroxyformic acid aqueous solution is 5h -1 ; 3) switch to methanol containing ammonium hydrogen phosphate and modify the aqueous solution for 10h, the concentration of ammonium hydrogen phosphate is 2.3mmol / L, the water content is 3wt%, and the mass space velocity of the mixed solution is 10h -1 ; 4) Rinse with a mixed aqueous solution of methanol and hydrogen peroxide for 5 hours, the content of hydrogen peroxide is 15wt%, and the mass space velocity is 3.0 hours -1 ; The modification was carried out at 60°C.

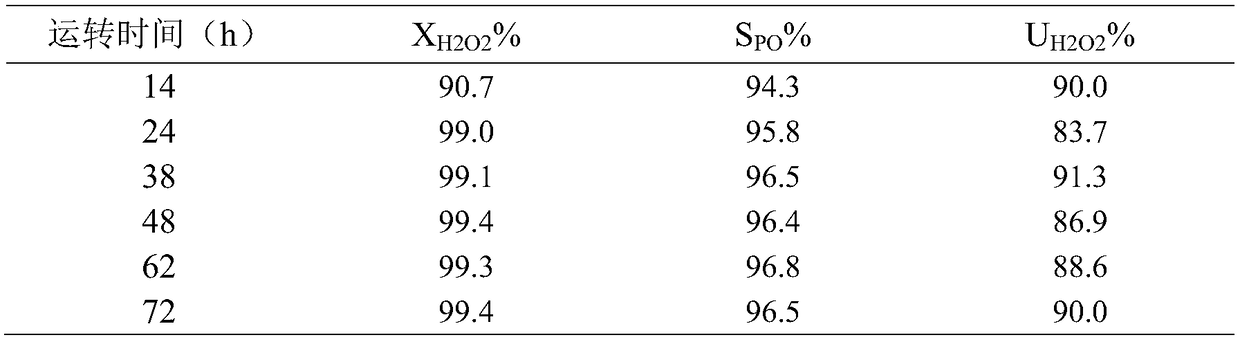

[0047] After the modification is completed, adjust the reaction temperature to 35°C, and switch the reaction raw materials. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com