High-temperature-resistant anti-oxidation anti-abrasion low-heat-expansion-coefficient aluminum tantalite ceramic material as well as preparation method and application thereof

A low thermal expansion coefficient, anti-oxidation technology, applied in the field of materials, can solve the problems of coating failure, huge thermal stress, high thermal expansion coefficient, and achieve the effect of low porosity, low preparation cost and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Weigh 2.0000 g of alumina and 8.6611 g of tantalum oxide, mix them in absolute ethanol, and mill them in a high-energy ball mill (the speed of the ball mill is 300 r / min, and the milling time is 720 min), and then the milled solution is mixed at 100 After drying at ℃ for 12 h, it passed through a 300-mesh sieve, and then it was pressed into a mold (holding pressure of 20 MPa and holding time of 10 min). After pressing, it was pre-fired at 1000 °C for 10 h.

[0042] After the first calcination of the raw material, the sample was taken out and cooled to room temperature, the mixture was ground evenly and passed through a 500-mesh sieve, and then pressed into a mold (the holding pressure was 6 MPa, and the holding time was 5 minutes). After pressing, It was calcined at 1550°C for 12 hours and cooled to room temperature to obtain the desired dense block aluminum tantalate (AlTaO 4 ) High temperature ceramic materials.

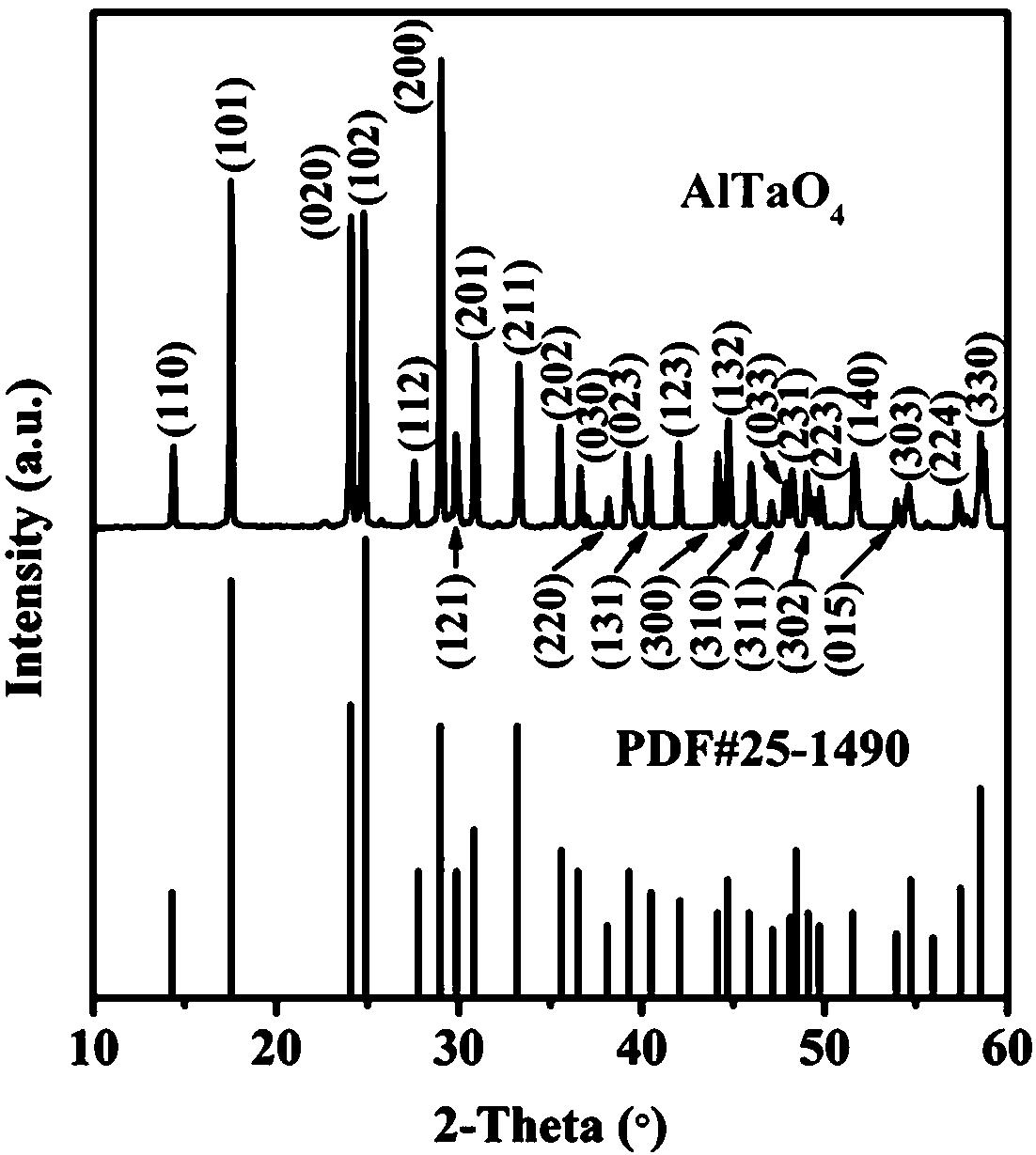

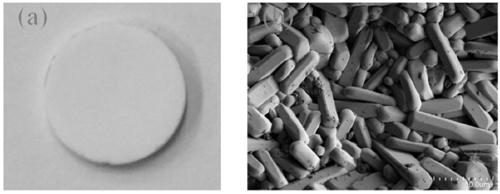

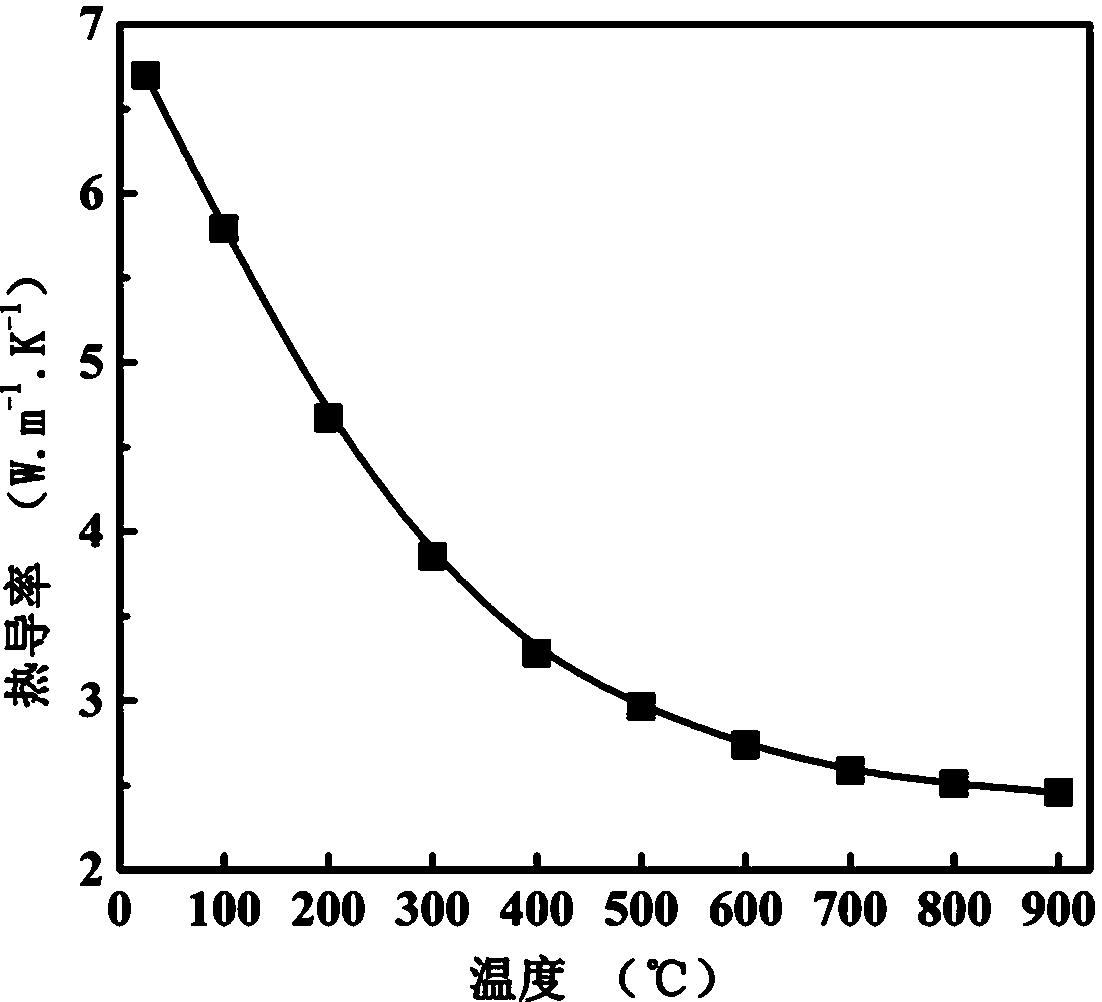

[0043] The bulk aluminum tantalate (AlTaO) prepared i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com