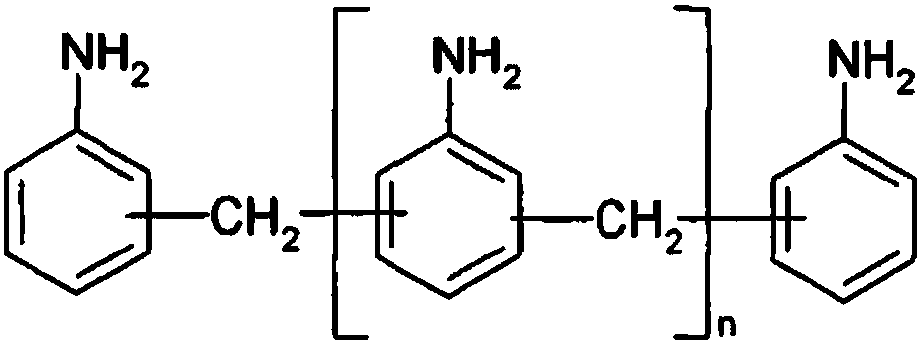

Preparation method of diphenylmethane series diamine and polyamine with low macromolecular impurity content

A technology of diphenylmethane and impurity content, applied in the preparation of amino compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve equipment pipeline blockage, poor mechanical mixing of formaldehyde, continuous and stable operation of product DAM quality effects, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

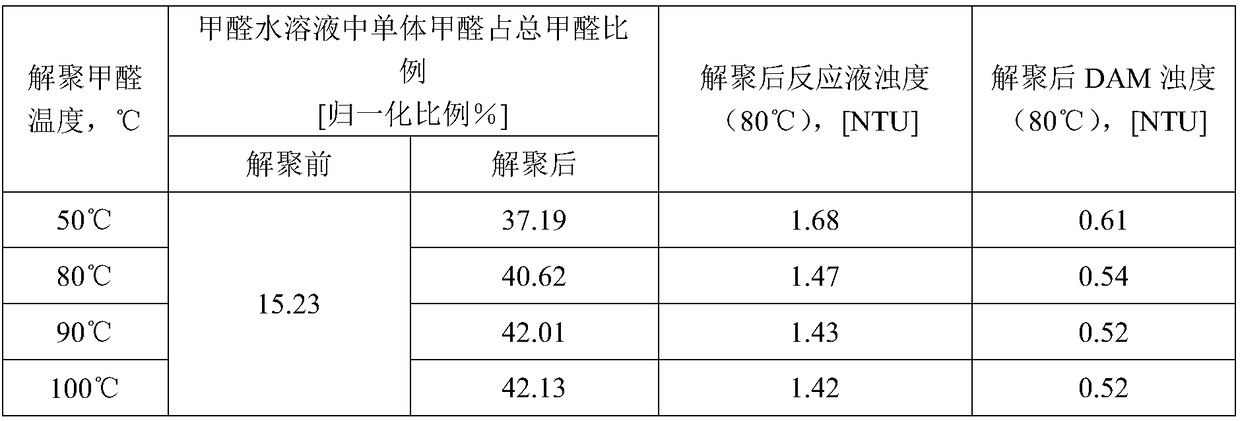

Embodiment 1

[0033] a) Add 14.5 g of acidic formaldehyde depolymerization catalyst hydrochloric acid (mass concentration 34%) into 109.5 g of clear and transparent formaldehyde aqueous solution (store at 50°C for 72 hours, formaldehyde mass concentration is 37%, pH is 3) and stir, condense and reflux 1. In the reactor replaced by nitrogen, heat at 50° C., 80° C., 90° C., 100° C. and 300 rpm for 2.5 hours in sequence.

[0034] b) Weigh 279.0g of aniline (mass concentration ≥ 99%) and 88.6g of hydrochloric acid (mass concentration 34%), and add them to another set of reactor with stirring and condensing reflux after nitrogen replacement, at 50°C and 300rpm React for 5 minutes, then add the depolymerized formaldehyde solution in step a) for 20 minutes, the stirring speed is 300 rpm, and the reaction temperature is controlled at 60°C. After the formaldehyde solution is added for 20 minutes, raise the system temperature to 80°C and continue At 40 minutes, the clear and transparent reaction solu...

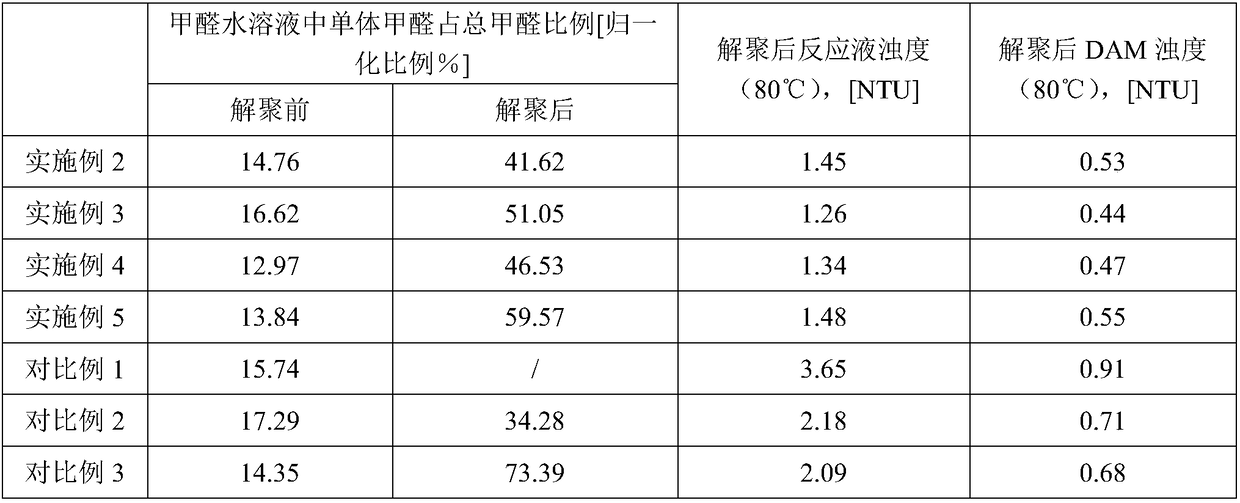

Embodiment 2

[0040] a) Add 2.9 g of acidic formaldehyde depolymerization catalyst hydrochloric acid (mass concentration 34%) into 101.3 g of clear and transparent formaldehyde aqueous solution (store at 50°C for 60 hours, formaldehyde mass concentration is 40%, pH is 3.5) and stir and condense Reflux in the reactor replaced by nitrogen, heat and reflux at 55°C and 300rpm for 1h, then add 4.2g isopropanol (mass concentration ≥ 99%) at 0.5ml / min, keep stirring and heat up to 1°C / min Heating to reflux at 85°C for 1.5h.

[0041] b) Weigh 279.0g of aniline (mass concentration ≥ 99%) and 100.2g of hydrochloric acid (mass concentration 34%), and add them to another set of reactor with stirring and condensing reflux after nitrogen replacement, at 50°C and 300rpm React at low temperature for 5 minutes, then add the depolymerized formaldehyde solution for 15 minutes, stir at 300 rpm, control the reaction temperature at 60°C, raise the system temperature to 80°C 20 minutes after the formaldehyde solu...

Embodiment 3

[0045] a) Add 17.4 g of acidic formaldehyde depolymerization catalyst sulfuric acid (mass concentration 38%) into 119.2 g of clear and transparent formaldehyde solution (store at 55°C for 52 hours, formaldehyde mass concentration is 34%, pH is 3) and stir and condense Reflux in the reactor replaced by nitrogen, heat and reflux at 50°C and 300rpm for 1h, then add 2.2g of anhydrous methanol (mass concentration ≥ 99%) at 0.5ml / min, keep stirring and heat up to 1°C / min Heating to reflux at 85°C for 1.5h.

[0046] b) Weigh 279.0g of aniline (mass concentration ≥ 99%) and 106.4g of sulfuric acid (mass concentration 38%), and add them to another set of reactor with stirring and condensing reflux after nitrogen replacement, at 50°C and 300rpm Then add the depolymerized formaldehyde solution for 20 minutes, the stirring speed is 300 rpm, and the reaction temperature is controlled at 60°C. After the formaldehyde solution is added for 20 minutes, raise the system temperature to 80°C and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com