Methyl chlorosilane separating device and method with internally heat integrated distillation towers

A monomethyltrichlorosilane, internal thermal coupling technology, applied in separation methods, distillation separation, chemical instruments and methods, etc., to achieve the effects of reducing investment, reducing steam consumption, and reducing process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

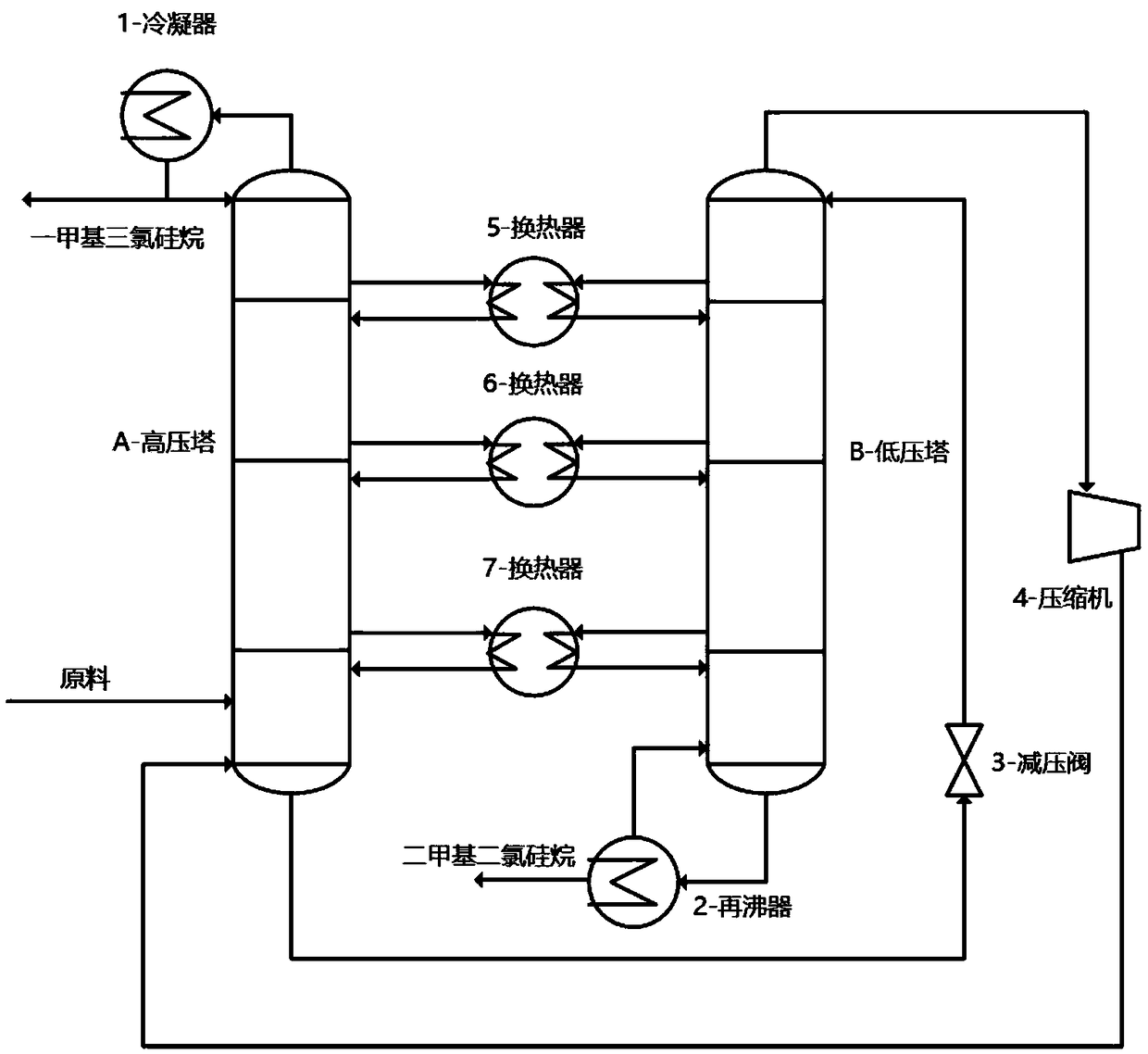

[0027] Such as figure 2 Shown, a kind of device that separates monomethyl trichlorosilane and dimethyl dichlorosilane, this device can be used for separating the high-purity methyl chlorosilane product, and it comprises the high-pressure rectification column A without reboiler, without The low-pressure rectification tower B of the condenser; the flow transfer between the two towers is carried out through the pressure reducing valve 3 and the compressor 4 to reduce / boost the pressure appropriately so as to meet the working conditions of the next tower. Considering the high requirement of product purity, 3 side lines are respectively drawn out between the two towers, and the heat is exchanged through the middle 3 heat exchangers 5 / 6 / 7 and then sent back to the same tray; There are raw material inlets, three side line gas phase extraction outlets and liquid phase return ports, and the side line extraction ports and return ports are all set on the same tray; the top of the tower ...

Embodiment example 1

[0032] Table 2 The main conditions of the device in implementation case 1

[0033]

[0034]

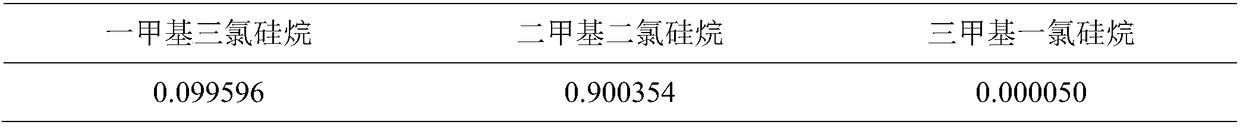

[0035] Table 3-Methyltrichlorosilane qualified product composition, mass fraction wt%

[0036]

[0037] Table 4 Dimethyldichlorosilane product composition, mass fraction wt%

[0038]

[0039] Table 5 Comparison of heating and cooling loads of new and old processes

[0040]

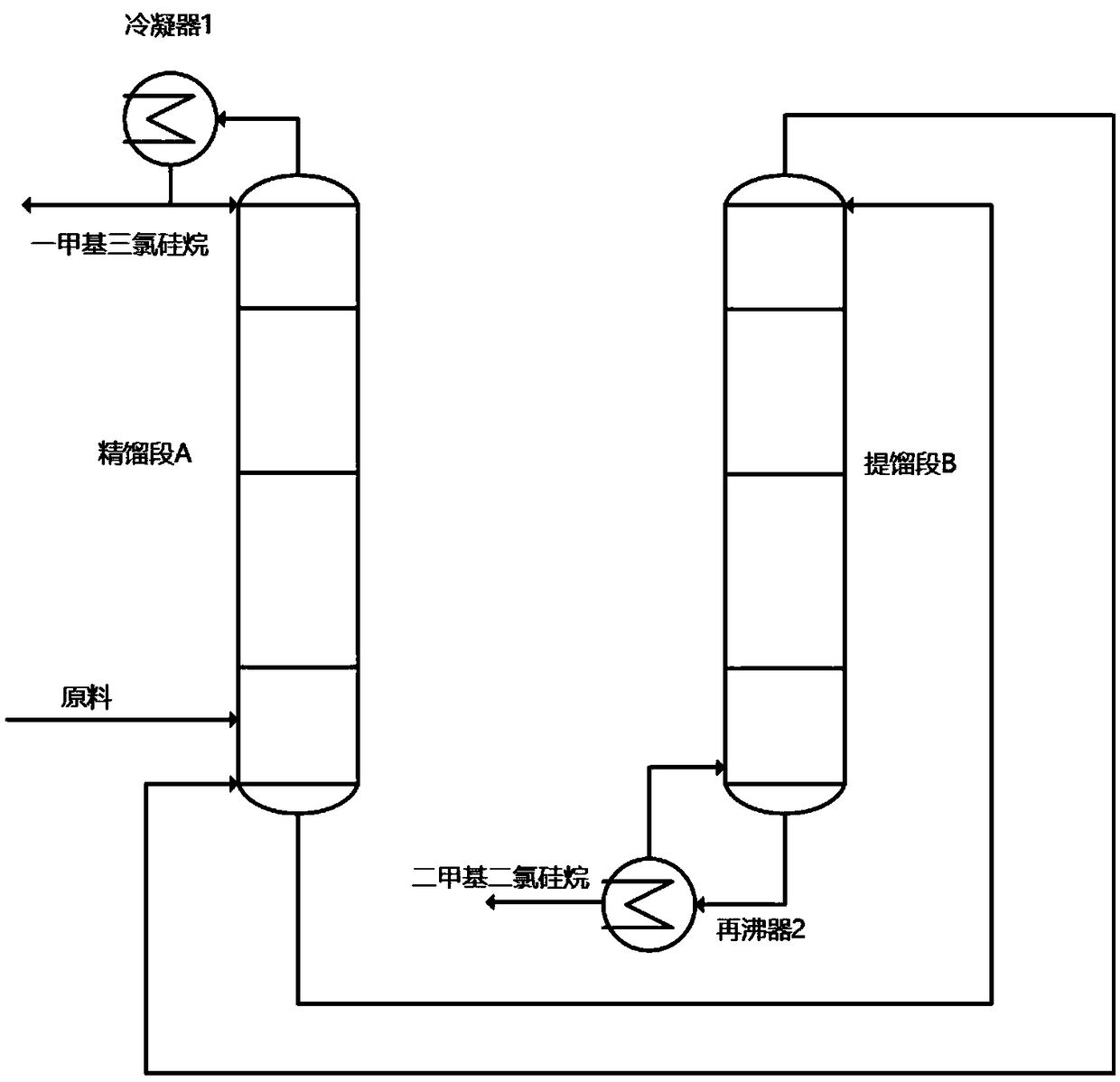

[0041] To sum up, this device achieves about 37% energy-saving effect of the traditional methylchlorosilane separation process through the discrete internal thermal coupling rectification technology, greatly reduces the consumption of cooling water and steam, and has significant economic benefits; and figure 1 Compared with the traditional separation process shown in the figure, the change range of this device is small, the overall structure is simple, the implementation difficulty is low, and it has obvious feasibility.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com