Preparation method of aromatic amides

An aromatic amide, p-phenylenediamine technology, applied in the direction of one-component copolyamide rayon, textile and papermaking, one-component synthetic polymer rayon, etc., can solve the problem of aramid fiber surface active groups less , poor ultraviolet radiation resistance, low fatigue resistance and other problems, to achieve the effect of improving solubility, increasing surface activity, and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

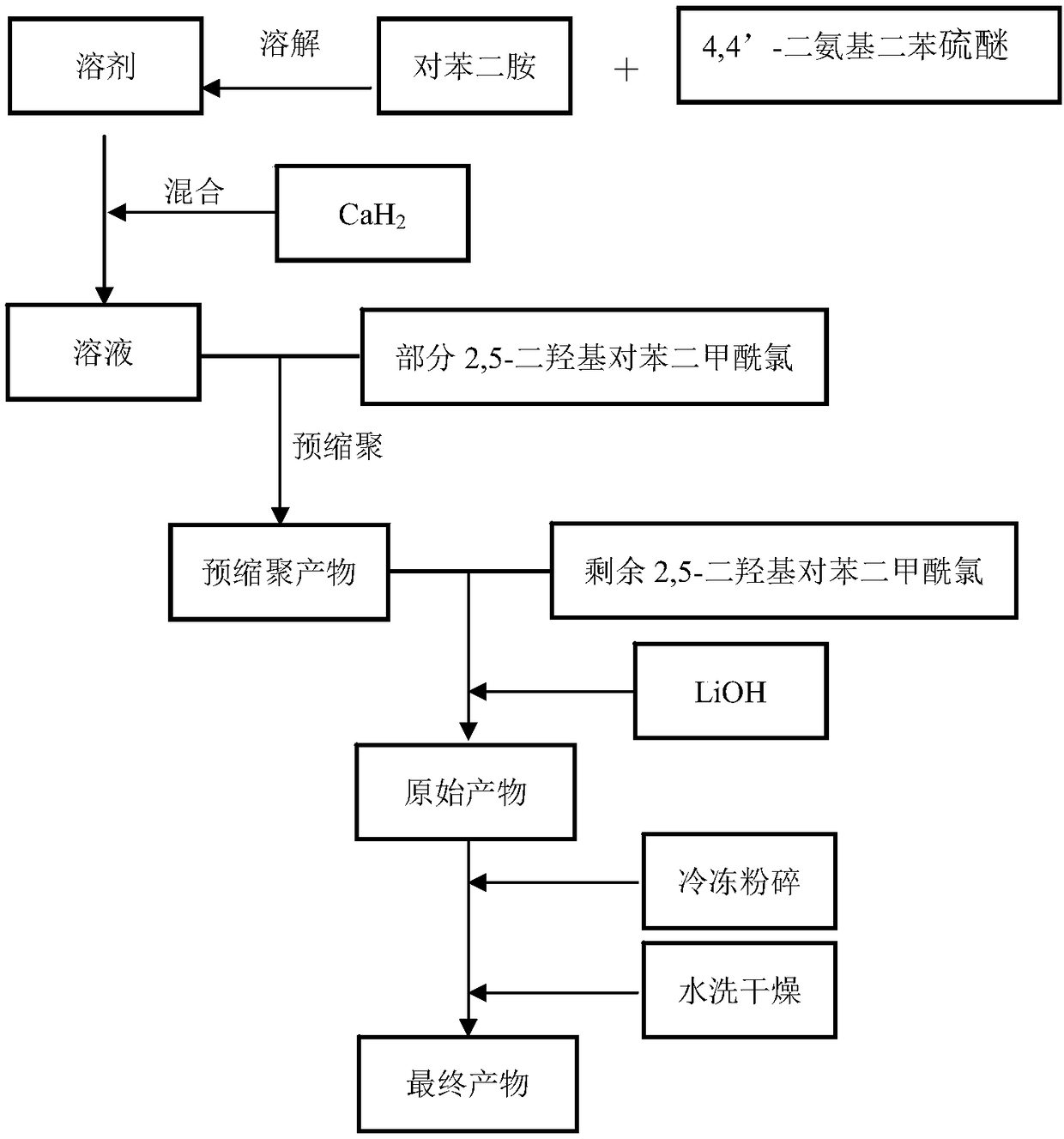

[0042] The preparation method of aromatic amide of the present invention, its process flow chart is as figure 1 shown, including the following steps:

[0043] (1) Under the environment of dry nitrogen protection, dissolve the p-phenylenediamine powder in N-methylpyrrolidone (NMP) at room temperature, so that the concentration of p-phenylenediamine is 0.8mol / L. After it is completely dissolved, add a certain amount of 4,4'-diaminodiphenyl sulfide and stir until it is completely dissolved, so that the concentration is 0.3mol / L, cool to -10°C with an ice-salt bath, add calcium hydride powder and stir evenly , the concentration of calcium hydride in the solution is 0.2mol / L;

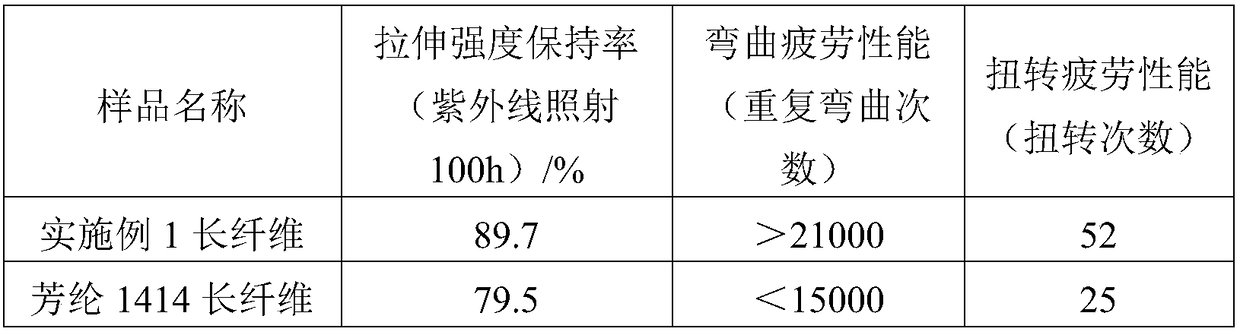

[0044] (2) First, add 2,5-dihydroxyterephthaloyl chloride in an amount of p-phenylenediamine addition of 85% to the solution after step (1) to react for 40 minutes, and control the reaction temperature at 25° C.; then add p-phenylenediamine in three batches Add 2,5-dihydroxyterephthaloyl chloride in an amo...

Embodiment 2

[0052] The preparation method of aromatic amide of the present invention, its process flow chart is as figure 1 shown, including the following steps:

[0053] (1) Under the environment of dry nitrogen protection, dissolve the p-phenylenediamine powder in N-methylpyrrolidone (NMP) at room temperature, so that the concentration of p-phenylenediamine is 0.5mol / L. After it is completely dissolved, add a certain amount of 4,4'-diaminodiphenyl sulfide and stir until it is completely dissolved, so that the concentration is 0.25mol / L, cool to -5°C with an ice-salt bath, add calcium hydride powder and stir evenly , the concentration of calcium hydride in the solution is 0.2mol / L;

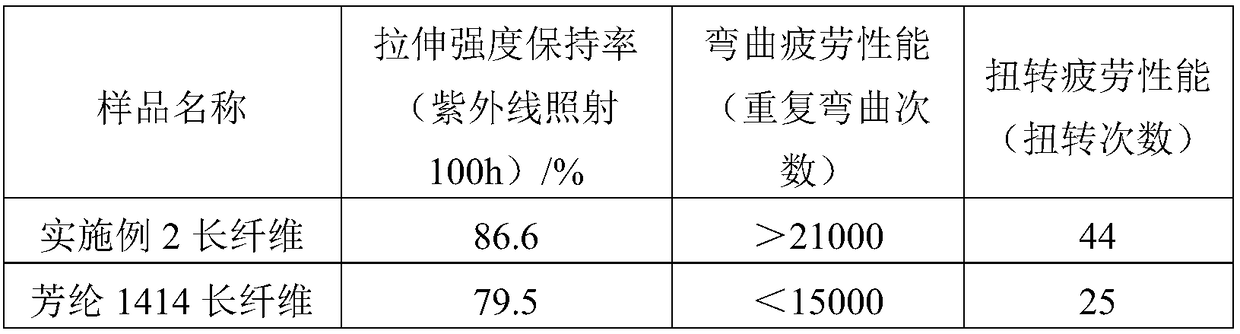

[0054] (2) First add 2,5-dihydroxyterephthaloyl chloride in an amount of 50% p-phenylenediamine to the solution after step (1) to react for 1 hour, and control the reaction temperature at 20°C; then add p-phenylenediamine in five batches Add 2,5-dihydroxyterephthaloyl dichloride in an amount of 50% of phen...

Embodiment 3

[0062] The preparation method of aromatic amide of the present invention, its process flow chart is as figure 1 shown, including the following steps:

[0063] (1) Under the environment of dry nitrogen protection, dissolve the p-phenylenediamine powder in N-methylpyrrolidone (NMP) at room temperature, so that the concentration of p-phenylenediamine is 0.6mol / L. After it is completely dissolved, add a certain amount of 4,4'-diaminodiphenyl sulfide and stir until it is completely dissolved, so that the concentration is 0.3mol / L, cool to -10°C with an ice-salt bath, add calcium hydride powder and stir evenly , the concentration of calcium hydride in the solution is 0.2mol / L;

[0064] (2) First, add 2,5-dihydroxyterephthaloyl chloride in an amount of 75% p-phenylenediamine addition to the solution after step (1) to react for 50 minutes, and control the reaction temperature at 30° C.; then add p-phenylenediamine in four batches Add 2,5-dihydroxyterephthaloyl chloride in an amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com