High-processability radiation crosslinked polyolefin cable material

A technology of cross-linked polyolefin and processing performance, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc. It can solve the problems of difficult control of the process, affecting the quality of finished products, and poor processing performance, so as to achieve not easy melt fracture, Improvement of production efficiency and improvement of dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

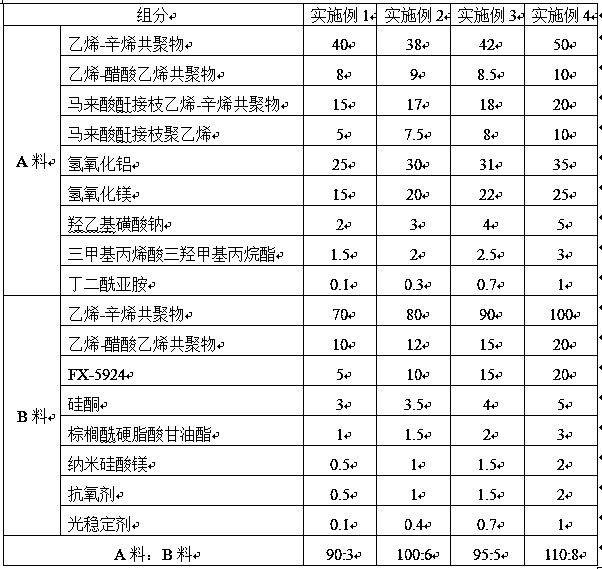

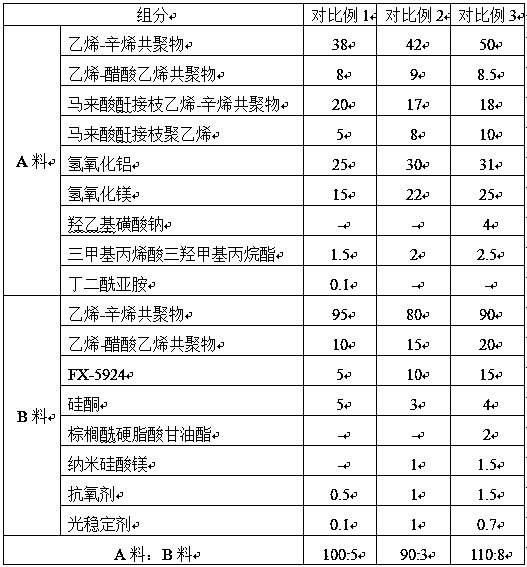

[0037] Embodiments 1-4: A high-processing performance radiation crosslinked polyolefin cable material, including the following components in parts by weight:

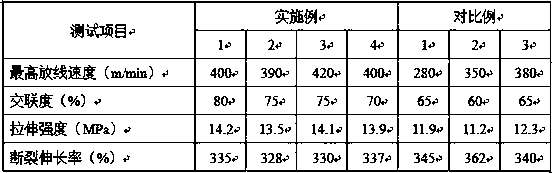

[0038] Table 1

[0039]

[0040] The radiation cross-linked polyolefin cable material with high processability is prepared through the following steps:

[0041] S1. Mix 70~100 parts of ethylene-octene copolymer, 10~20 parts of ethylene-vinyl acetate copolymer, 5~20 parts of FX-5924, 3~5 parts of silicone, 1~3 parts of glyceryl palmitoyl stearate Parts, 0.5~2 parts of nano-magnesium silicate, 0.5~2 parts of antioxidant, 0.1~1 part of light stabilizer are added to the internal mixer to mix and plasticize, and then conveyed into the screw extruder through double-cone shearing for extrusion, water Strand granulation to obtain the B material;

[0042] S2. 36~50 parts of ethylene-octene copolymer, 8~10 parts of ethylene-vinyl acetate copolymer, 15~20 parts of maleic anhydride grafted ethylene-octene copolymer, 5~20 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com