Uvioresistant color masterbatches for polypropylene and preparation process of uvioresistant color masterbatches

A polypropylene, anti-ultraviolet technology, applied in the field of anti-ultraviolet color masterbatch for polypropylene and its preparation, can solve the problems of poor comprehensive use performance, poor thermal stability, poor mechanical properties, etc., and achieve good comprehensive use performance and composition distribution. The effect of reasonable ratio and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

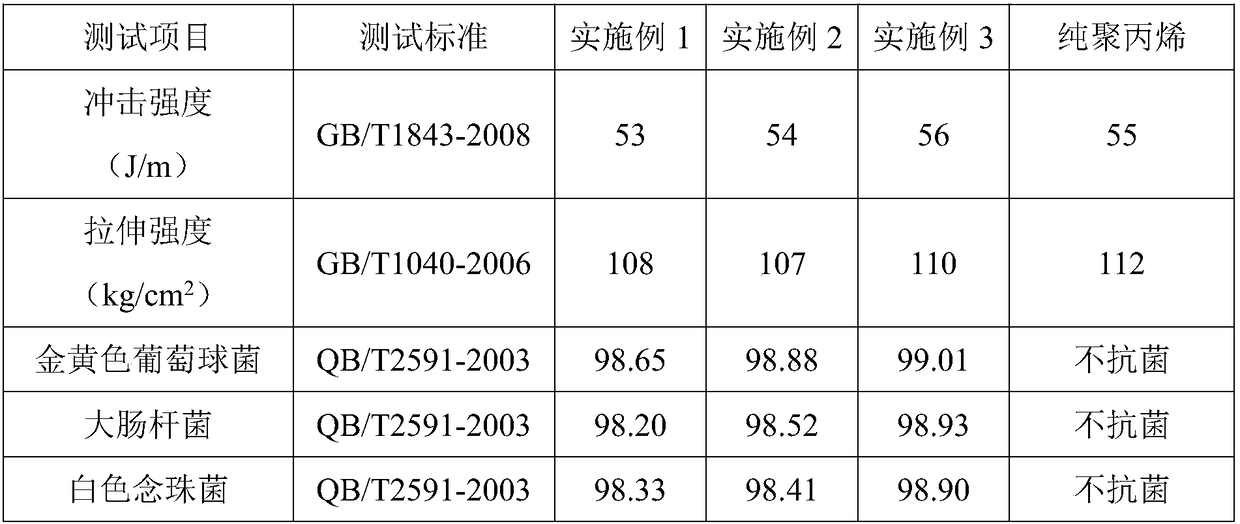

Examples

Embodiment 1

[0030] Example 1: An anti-ultraviolet color masterbatch for polypropylene, prepared from the following raw materials by weight: 60 parts of polypropylene, 10 parts of ethylene-vinyl acetate copolymer, 7 parts of polyolefin elastomer, styrene maleate 3 parts of acid anhydride copolymer, 1.5 parts of zinc stearate, 1.7 parts of calcium stearate, 12 parts of pigment, 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-benzochlorination 0.35 parts of triazole, 0.2 parts of 2-hydroxy-4-methoxybenzophenone, 0.2 parts of 2-hydroxy-4-n-octyloxybenzophenone, 1.5 parts of silver nitrate, bis(2,4-bis(2,4-di) 3.5 parts of tert-butylphenyl) propionic acid] pentaerythritol diphosphite, and 4 parts of 2,5 dimethyl-2,5 di-tert-butylperoxide hexane.

[0031] Preferably, the number average molecular weight of the styrene maleic anhydride copolymer is 5000 g / mol, and the maleic anhydride content is 35%.

[0032] Preferably, the pigment is an organic pigment.

[0033] More preferably, the organic pigments ar...

Embodiment 2

[0039] Embodiment 2: A kind of anti-ultraviolet color masterbatch for polypropylene, described anti-ultraviolet color masterbatch for polypropylene is prepared from the following raw materials by weight: 80 parts of polypropylene, 14 parts of ethylene-vinyl acetate copolymer, poly 10 parts of olefin elastomer, 4.5 parts of styrene maleic anhydride copolymer, 2.3 parts of zinc stearate, 2.4 parts of calcium stearate, 17 parts of pigment, 2-(2'-hydroxy-3',5'-ditertiary 0.8 parts of phenyl)-5-chlorinated benzotriazole, 0.35 parts of 2-hydroxy-4-methoxybenzophenone, 0.55 parts of 2-hydroxy-4-n-octyloxybenzophenone, silver nitrate 2.4 parts, 5.5 parts of bis(2,4-di-tert-butylphenyl) propionate] pentaerythritol diphosphite, and 6 parts of 2,5-dimethyl-2,5-di-tert-butylperoxyhexane.

[0040] Preferably, the number average molecular weight of the styrene-maleic anhydride copolymer is 6000 g / mol, and the maleic anhydride content is 40%.

[0041] Preferably, the pigment is an inorganic...

Embodiment 3

[0048] Embodiment 3: A kind of anti-ultraviolet color masterbatch for polypropylene, described anti-ultraviolet color masterbatch for polypropylene is prepared from the following raw materials by weight: 75 parts of polypropylene, 13 parts of ethylene-vinyl acetate copolymer, poly 9 parts of olefin elastomer, 4 parts of styrene maleic anhydride copolymer, 2.2 parts of zinc stearate, 2.1 parts of calcium stearate, 15.5 parts of pigment, 2-(2'-hydroxy-3',5'-ditertiary 0.55 parts of phenyl)-5-chlorinated benzotriazole, 0.3 parts of 2-hydroxy-4-methoxybenzophenone, 0.35 parts of 2-hydroxy-4-n-octyloxybenzophenone, silver nitrate 2.2 parts, 4.5 parts of bis(2,4-di-tert-butylphenyl) propionate] pentaerythritol diphosphite, and 5.5 parts of 2,5-dimethyl-2,5-di-tert-butylperoxyhexane.

[0049] Preferably, the number average molecular weight of the styrene-maleic anhydride copolymer is 5500 g / mol, and the maleic anhydride content is 37.5%.

[0050] Preferably, the pigment is an organi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com