Method for immobilizing antifouling enzyme on surface of inorganic coating

An inorganic coating, anti-fouling enzyme technology, applied in anti-fouling/underwater coatings, coatings, anti-corrosion coatings, etc. Poor transparency and other problems, to achieve good anti-corrosion and anti-fouling performance, simple and feasible preparation method, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

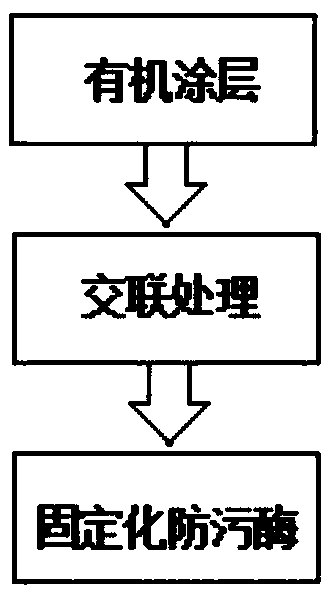

[0018] The process of the immobilization method of the antifouling enzyme on the surface of the inorganic coating involved in this embodiment comprises three steps of preparing an organic coating, cross-linking treatment and immobilizing the antifouling enzyme:

[0019] (1) Preparation of organic coating: Add tetraethyl orthosilicate alkane to silica sol with a pH value of 4.0, hydrolyze it at 45°C for 1 hour to form a mixed solution, and add diethylenetriaminopropyl trimethyl to the mixed solution Oxysilane, mixed evenly and coated on the coating film, forming an organic coating on the coating film;

[0020] The mass ratio of silica sol to tetraethyl orthosilicate alkane is 0.8, and the mass of diethylenetriaminopropyltrimethoxysilane accounts for 0.1% of the mass of the mixed solution;

[0021] (2) Cross-linking treatment: glutaraldehyde is added to a phosphate buffer solution with a pH value of 7 to prepare a glutaraldehyde solution with a mass percent concentration of 5%, ...

Embodiment 2

[0024] The process of the immobilization method of the antifouling enzyme on the surface of the inorganic coating involved in this embodiment comprises three steps of preparing an organic coating, cross-linking treatment and immobilizing the antifouling enzyme:

[0025] (1) Preparation of organic coating: Add methyltriethoxysilane to silica sol with a pH value of 5.0, hydrolyze at 50°C for 2 hours to form a mixed solution, and add (3-aminopropyl) to the mixed solution Trimethoxysilane, after mixing evenly, is coated on the film-coated sheet, and an organic coating is formed on the film-coated sheet;

[0026] The mass ratio of silica sol to methyltriethoxysilane is 1.3, and the mass of (3-aminopropyl)trimethoxysilane accounts for 3.0% of the mass of the mixed solution;

[0027] (2) Cross-linking treatment: glutaraldehyde is added to a phosphate buffer solution with a pH value of 7 to prepare a glutaraldehyde solution with a mass percent concentration of 5%, and the coated film ...

Embodiment 3

[0030] The process of the immobilization method of the antifouling enzyme on the surface of the inorganic coating involved in this embodiment comprises three steps of preparing an organic coating, cross-linking treatment and immobilizing the antifouling enzyme:

[0031] (1) Preparation of organic coating: Add methyltrimethoxysilane to silica sol with a pH value of 5.0, hydrolyze it at 60°C for 0.5h to form a mixed solution, and add (3-aminopropyl) to the mixed solution Triethoxysilane, mixed evenly and coated on the coating film, forming an organic coating on the coating film;

[0032] The mass ratio of silica sol to methyltrimethoxysilane is 1.0, and the mass of (3-aminopropyl)triethoxysilane accounts for 5.0% of the mass of the mixed solution;

[0033] (2) Cross-linking treatment: glutaraldehyde is added to a phosphate buffer solution with a pH value of 7 to prepare a glutaraldehyde solution with a mass percent concentration of 5%, and the coated film is immersed in the glut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com