High entropy amorphous alloy coating and preparation method thereof

An amorphous alloy and coating technology, applied in metal material coating process, coating and other directions, can solve the problems such as the preparation of amorphous coatings by broadband lasers that have not yet been found, and achieve lower material costs, uniform and dense interior, and high amorphous The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0033] The preparation method of the high-entropy amorphous alloy coating of the present embodiment is specifically as follows:

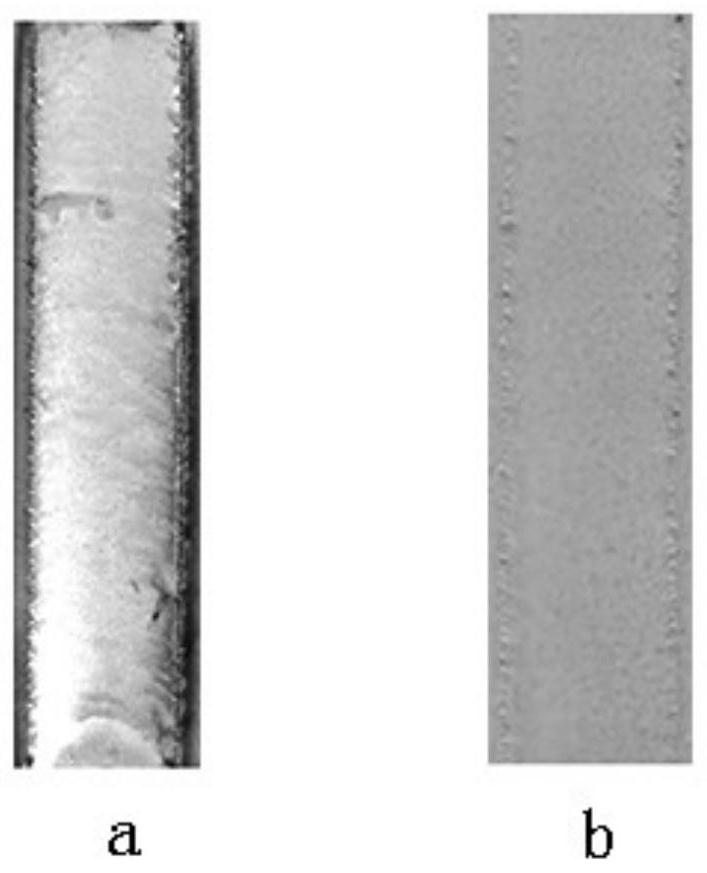

[0034] S1: Substrate pretreatment.

[0035] Select No. 45 steel with a size of 140mm×100mm×8mm as the substrate; sand paper to remove oxides on the surface of the substrate; ultrasonic cleaning with absolute ethanol to remove abrasive debris and oil stains on the surface of the substrate.

[0036] S2: Alloy powder preparation.

[0037] The components and mass percentages of the alloy powder in this embodiment are as follows: 30% nickel, 30% cobalt, 4% silicon, 4% boron, and the balance is iron.

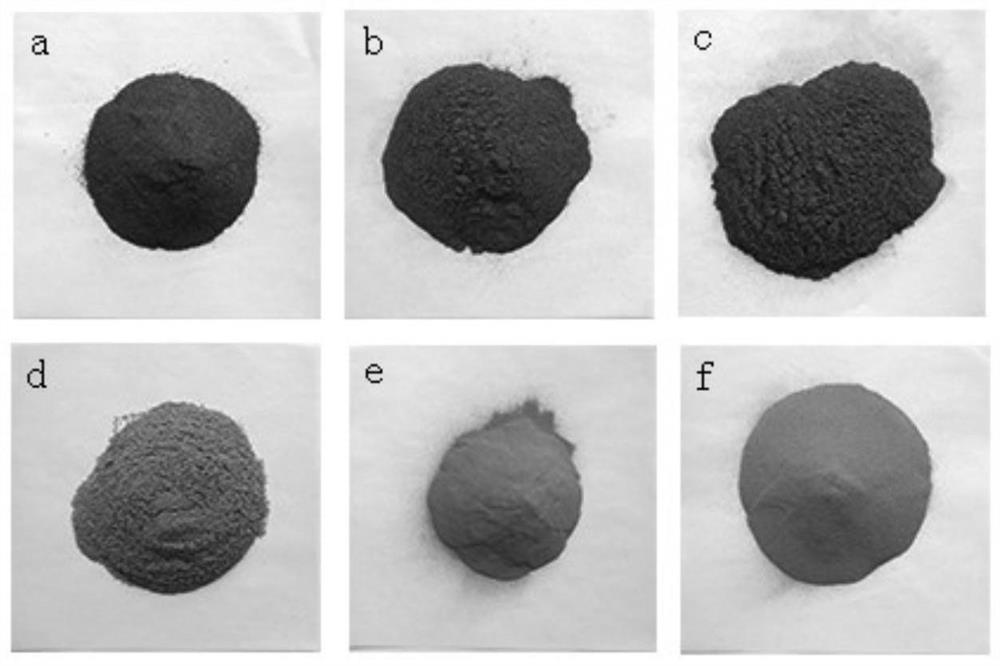

[0038] Atomize pure iron powder with an iron content of 99.9wt% [see the appearance schematic diagram figure 1 Figure f in the figure], pure nickel atomized powder with a nickel content of 99.9wt% [appearance schematic diagram, see figure 1 Figure e in the figure], pure cobalt atomized powder with a cobalt content of 99.9wt% [appearance schematic diagram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com