A kind of protective agent of high stability gardenia yellow pigment and the preparation process and coloring process of high stability gardenia yellow pigment

A gardenia yellow pigment with high stability technology, which is applied in food science and other fields, can solve the problems of shortening dyeing time and instability of gardenia yellow, achieve food safety, improve light fastness, high temperature resistance and light fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

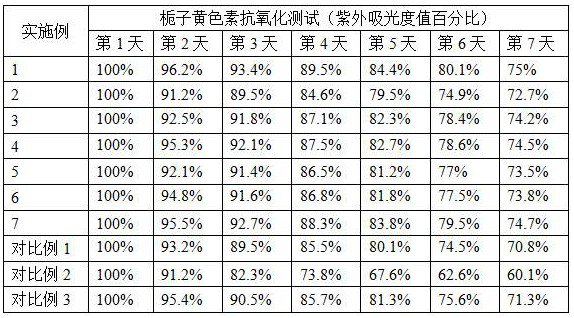

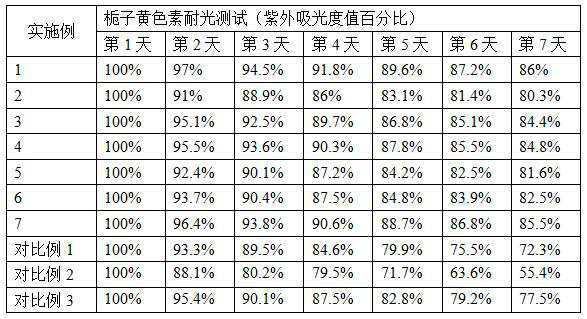

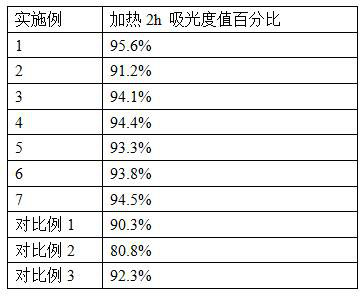

Examples

Embodiment 1

[0031] The protective agent preparation method of the present embodiment is as follows:

[0032] The bamboo leaf antioxidant required in the formula is made by crushing the bamboo leaves with a ball mill, passing through a 800-mesh sieve, and mixing the crushed bamboo leaf powder and 70% ethanol at a ratio of 1:15 (w:v) ;Using microwave technology, constant temperature 50°C, treatment for 15min, cooling to room temperature, centrifugation to take the supernatant; Rotary evaporation of the supernatant, at a temperature of 50°C and a vacuum of 0.08MPa, rotary evaporation for 15min; after rotary evaporation The concentrated solution was separated by a polyamide column, and the filtrate was eluted with 70% ethanol; the eluate was freeze-dried at a temperature of -60°C and a vacuum of 0.092MPa to finally obtain bamboo leaf antioxidant powder.

[0033] Protective agent preparation raw materials: ethylenediaminetetraacetic acid disodium (EDTA-2Na): 0.075g, licorice extract: 0.2g, bam...

Embodiment 2

[0040] The protective agent preparation method of the present embodiment is as follows:

[0041] The bamboo leaf antioxidant required by the formula is obtained by pulverizing the bamboo leaves with a ball mill, passing through a 800-mesh sieve, and mixing the pulverized bamboo leaf powder with 80% ethanol at a ratio of 1:20 (W:V) , using microwave technology, constant temperature 60°C, treatment for 15min, cooling to room temperature, centrifugation to take the supernatant; rotary evaporation of the supernatant, at a temperature of 60°C and a vacuum of 0.095MPa, rotary evaporation for 10min; the rotary evaporated The concentrated solution was separated by a polyamide column, and the filtrate was eluted with 80% ethanol; the eluate was freeze-dried at a temperature of -70°C and a vacuum of 0.100 MPa to finally obtain bamboo leaf antioxidant powder.

[0042] Protective agent preparation raw materials: disodium ethylenediaminetetraacetic acid (EDTA-2Na): 0.03g, licorice extract:...

Embodiment 3

[0049] The protective agent preparation method of the present embodiment is as follows:

[0050] The bamboo leaf antioxidant required by the formula is obtained by pulverizing the bamboo leaves with a ball mill, passing through a 800-mesh sieve, and mixing the pulverized bamboo leaf powder and 75% ethanol at a ratio of 1:16 (W:V) , by adopting microwave technology, constant temperature 55℃, treatment for 12min, cooling to room temperature, centrifugation to take the supernatant; the supernatant was subjected to rotary evaporation, at a temperature of 55℃ and a vacuum of 0.09MPa, rotary evaporation for 13min, after rotary evaporation The concentrated solution was separated by a polyamide column, and the filtrate was eluted with 75% ethanol; the eluate was freeze-dried at a temperature of -65°C and a vacuum of 0.095 MPa to finally obtain bamboo leaf antioxidant powder.

[0051] Protective agent preparation raw materials: ethylenediaminetetraacetic acid disodium (EDTA-2Na): 0.06g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com