Method for preparing series of neoagarool igosaccharode with single degree of polymerization by utilizing immobilized enzyme

A new agar oligosaccharide, immobilized enzyme technology, applied in biochemical equipment and methods, microorganism-based methods, immobilized on or in inorganic carriers, etc., can solve the problem that the activity is easily affected by enzymatic hydrolysis conditions, product separation Purification effect, difficulty in rapid development and other problems, to achieve the effect of simple and effective immobilization method, reuse, and simplify post-processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation of embodiment 1 agarase enzyme liquid

[0026] Vibrio natriegens HJPHYXJ-1 (disclosed in patent application 201510390422.9, agarase-producing vibrio natriegens and its application, publication number CN105087427A, is preserved in China Type Culture Collection Center, address: Wuhan, China , Wuhan University, postal code: 430072, preservation number: CCTCC M2015244, preservation date: April 23, 2015) transferred from the slant culture medium to the seed culture medium, obtained the seed liquid by shaking culture, and inoculated the seed liquid into the liquid medium In this method, the inoculum size is 6%, the fermentation temperature is 35°C, the stirring speed is 100rpm, and the fermentation time is 48h. The supernatant obtained after the fermentation broth is centrifuged to remove bacteria is separated by ammonium sulfate precipitation, dialyzed, and finally freeze-dried to obtain agarase powder.

[0027] See CN105087427A for the specific formulations ...

Embodiment 2

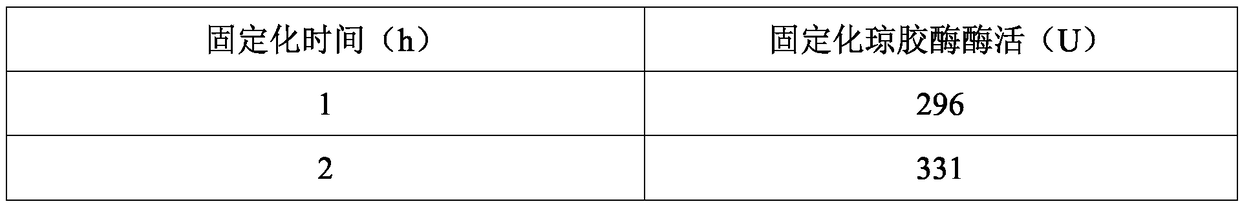

[0028] The preparation of embodiment 2 immobilized enzyme

[0029] (1) Take 1.0g of graphene oxide (GO) and add it to 80mL of 60% ethanol solution. After ultrasonic dispersion for 0.5h, add 0.676g of ferric chloride hexahydrate and 0.695g of ferrous sulfate heptahydrate, and continue ultrasonication for 20min. Add 3.5mol L ~1 After 100 mL of ammonia solution was reacted at reflux temperature of 60 °C for 2 h, the product was separated with a magnet, washed with deionized water until neutral, and dried to obtain GO / Fe 3 o 4 Composite magnetic carrier.

[0030] The above-mentioned ferric chloride hexahydrate can also be replaced with at least one of other ferric chloride or its hydrate, ferric sulfate or its hydrate and iron nitrate or its hydrate of the same molar amount, and the above-mentioned ferrous sulfate heptahydrate can also be It can be replaced with at least one of other ferrous sulfate heptahydrate or its hydrates, ferrous chloride or its hydrates, and ferrous nit...

Embodiment 3

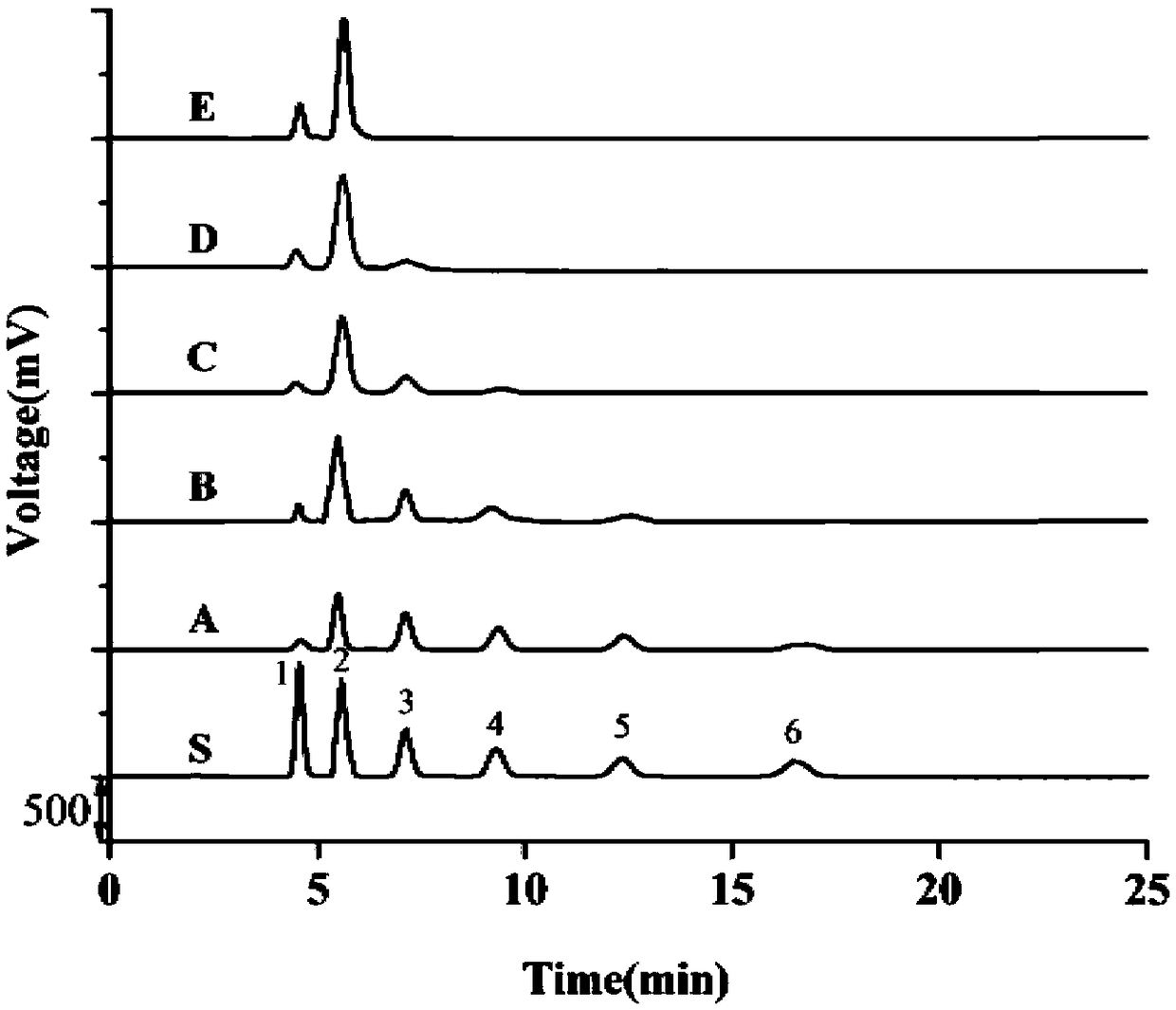

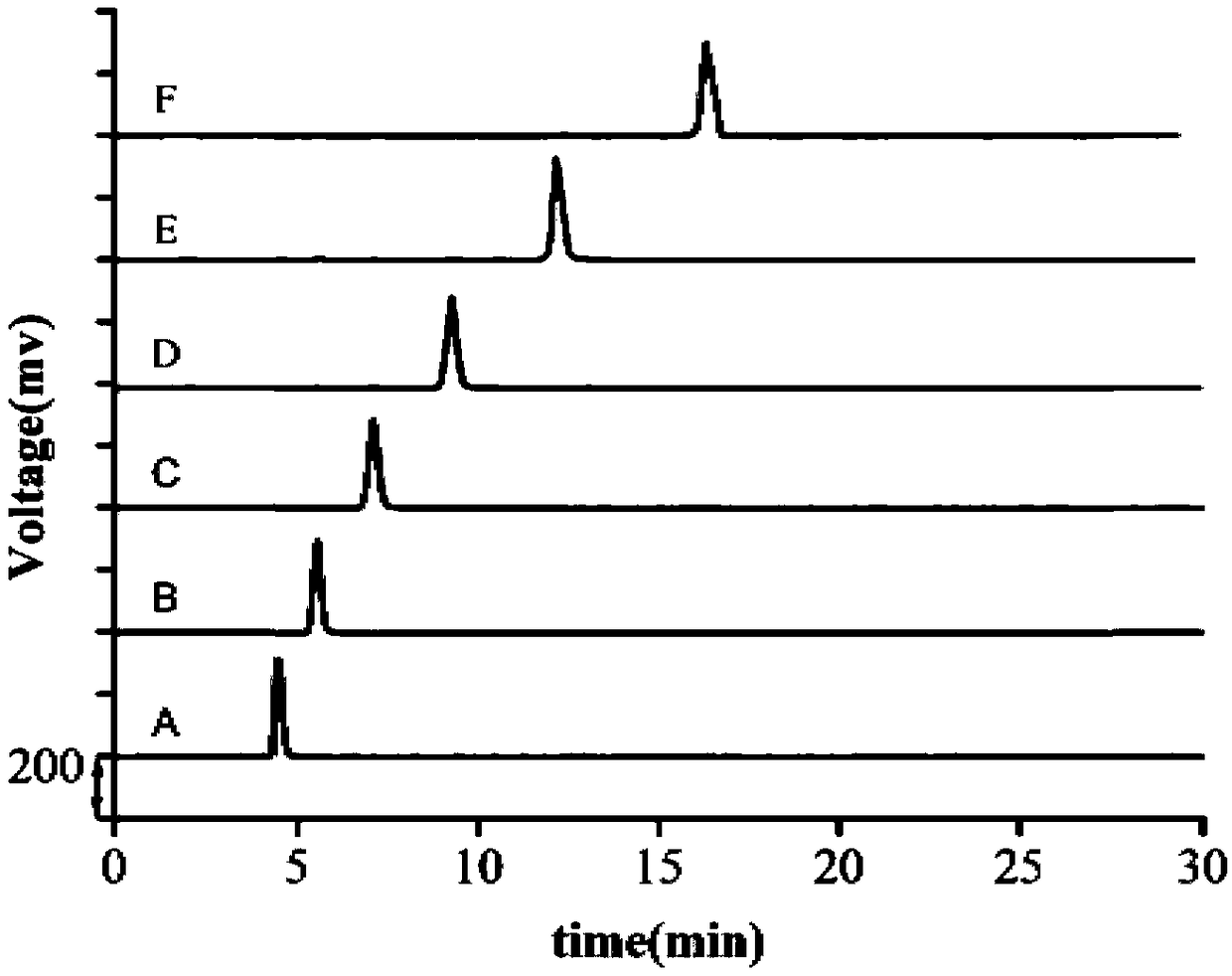

[0032] The influence of embodiment 3 glutaraldehyde concentration on immobilized agarase enzymatic activity

[0033] Agarase and immobilized carrier preparation and immobilization method refer to Examples 1 and 2, the difference is that when immobilizing the enzyme, the volume concentration of glutaraldehyde aqueous solution is 1%, 2%, 3%, 4%, 5%.

[0034] Table 1 Effect of glutaraldehyde concentration on immobilized agarase activity

[0035] Glutaraldehyde concentration (%)

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com