Method for improving cohesiveness of hemp/resin composite material interface

A resin composite material and bonding technology, applied in the direction of enzyme/microbial biochemical treatment, liquid repellent fiber, biochemical fiber treatment, etc., can solve the problem of residual chemical harmful substances, prone to homopolymerization reaction, and reduce the utilization of monomers efficiency and other issues, to achieve the effects of strong substrate selectivity, environmentally friendly processing, and significant modification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following uses jute fiber as the representative of hemp fiber, octadecylamine as the hydrophobic exogenous amine monomer, and polylactic acid (PLA) resin to explain this plan in detail.

[0025] Jute fibers were modified by laccase / TEMPO catalyzed grafting hydrophobization with octadecylamine as an exogenous monomer, and then melt-blended with polylactic acid (PLA) resin-extrusion injection molding to prepare jute / PLA composites.

[0026] Add 0.50g laccase, 0.70g TEMPO, 1.35g octadecylamine and 10g jute fiber to 500mL acetic acid-sodium acetate buffer solution with pH value 4.5 at the same time, react at 50°C for 12h, then fully wash with water, extract with ethanol Wash and dry at room temperature.

[0027] (1) Elemental analysis of jute fiber

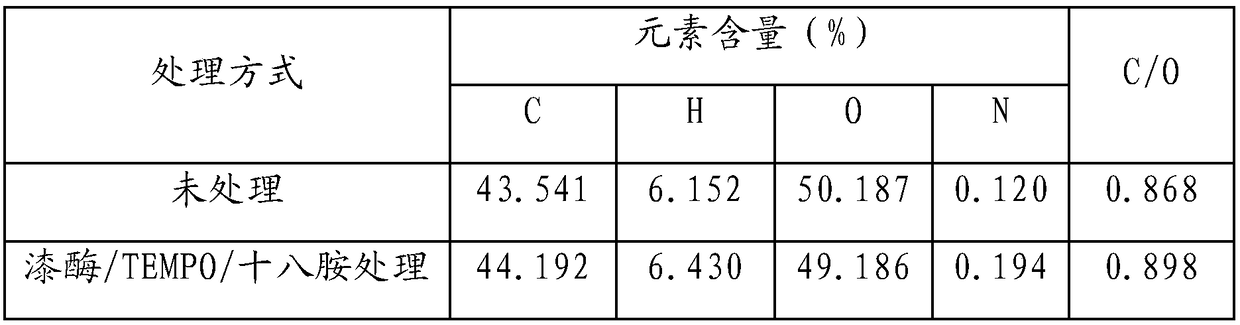

[0028] Table 1 Element content and carbon-oxygen ratio comparison table after different treatment

[0029]

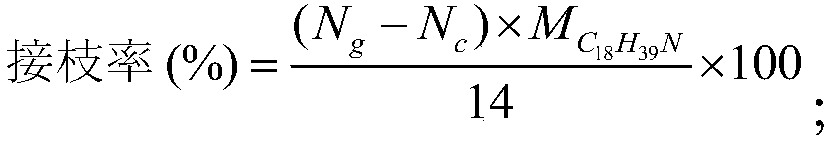

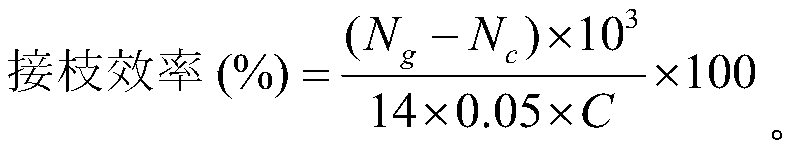

[0030] The enzymatic grafting of octadecylamine to jute fiber increases the nitrogen content, so the grafting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface free energy | aaaaa | aaaaa |

| surface free energy | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com