Communication transformer and manufacturing method thereof

A manufacturing method and transformer technology, applied in the manufacture of inductors/transformers/magnets, chemical instruments and methods, transformer/inductor cores, etc., can solve problems such as poor economy, easy oxidation of the surface, short service life, etc., and achieve improved use The effect of improving life and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

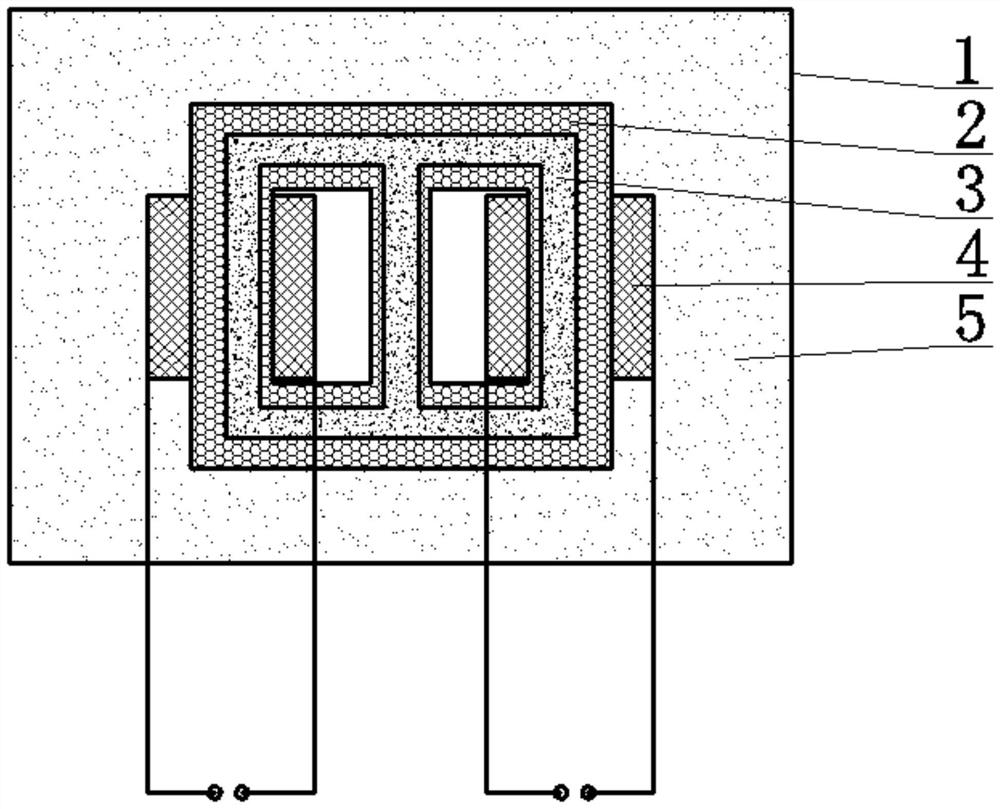

[0039] Such as figure 1 A communication transformer shown includes a skeleton, a winding 4, a magnetic core 3, a shielding cover 1 and packaging materials, wherein the skeleton is an alumina-based porous foam ceramic skeleton 2 with a porosity of 20%-30%; 1140 copper wire of epoxy polyester insulating varnish; the magnetic core 3 is a sun-shaped molybdenum permal magnetic core 3; the gap between the shielding cover 1 and other parts is filled with self-circulation insulation heat transfer filler 5, and the self-circulation insulation conduction The thermal filler 5 is a mixture of alumina-based porous foam ceramics and gum rosin; the shielding cover 1 is made of surface-activated and passivated titanium-containing low-carbon steel, and is packaged in a fully enclosed structure.

[0040] The manufacturing method of the communication transformer comprises the following steps:

[0041] 1) Selection and preparation of various components

[0042] ① The skeleton is selected from t...

Embodiment 2

[0067] The whole is consistent with Example 1, the difference is:

[0068] The manufacturing method of the communication transformer comprises the following steps:

[0069] 3) Manufacturing method of self-circulating insulating heat transfer filler 5

[0070] ① Mix aluminum chloride hexahydrate with an appropriate amount of pure water, stir and filter impurities, and prepare to obtain an aluminum chloride solution with a mass percentage of 58%;

[0071] ③ After step ② is completed, continue to vibrate at high frequency for 30 minutes, then place the solution to be treated in step ② in a constant temperature environment of 25 ° C, and mechanically stir for 30 minutes to obtain a prefabricated solution;

[0072] ④ Slowly add dilute hydrochloric acid solution dropwise to the prefabricated solution obtained in step ③ and stir until the pH value of the solution is 5.2, and leave to obtain the original sol solution;

[0073] ⑤ Place the original sol solution obtained in step ④ at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com