Lithium bis(fluorosufonyl)imide/1, 3-dioxolane lithium battery gel electrolyte, preparation method thereof and battery

A technology of lithium bisfluorosulfonimide and gel electrolyte, which is applied in the directions of lithium storage battery, secondary battery, electrolyte immobilization/gelation, etc., to achieve the effect of simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] With lithium bisfluorosulfonyl imide as the solute and 1,3-dioxane as the solvent, configure 3.5molL in a glove box protected by an argon atmosphere (water content-1 Lithium bisfluorosulfonyl imide / 1,3-dioxane electrolyte, and the Celgard 2400 diaphragm was immersed in the electrolyte, and after 24 hours at room temperature, a gel electrolyte was formed. Then assemble lithium / copper and lithium / lithium button batteries (CR2025) to test the cycle efficiency and cycle stability of the lithium metal anode material, the diameter of the lithium sheet is 12mm, and the diameter of the copper sheet is 18mm.

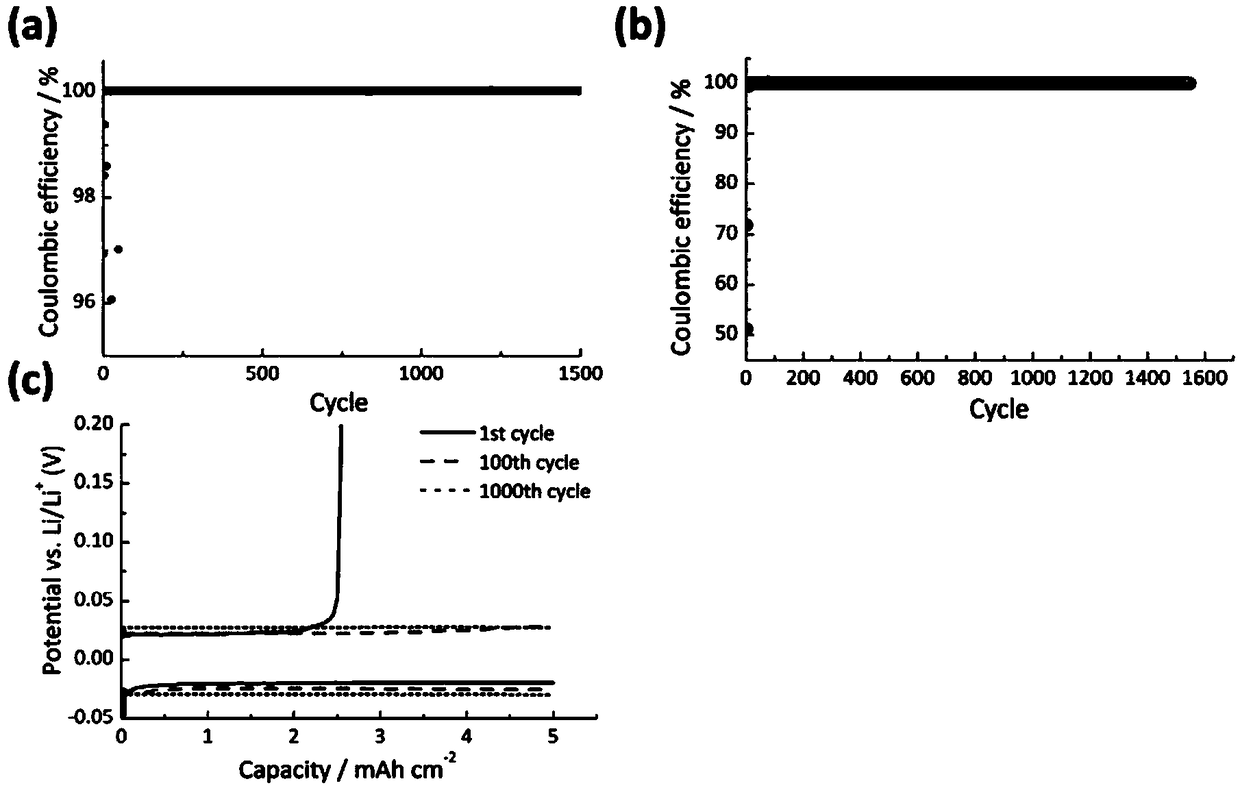

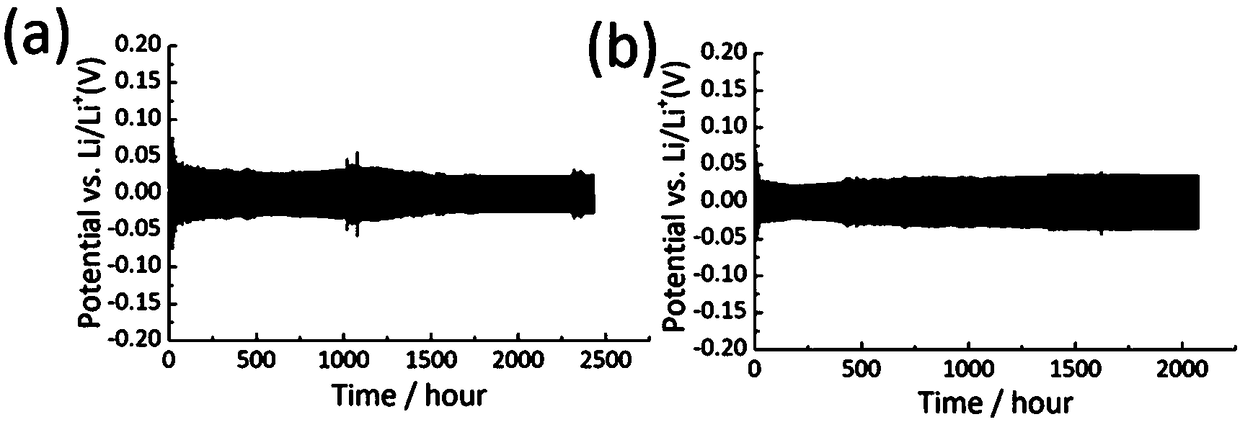

[0031] Figure 4 Cycle efficiency of lithium / copper button cells prepared for this example. figure 1 .a The current density is 2mAcm -2 , figure 1 .b and figure 1 .c The current density is 5mAcm -2 , the charging cut-off voltage is 1V vs. Li / Li + . from figure 1 It can be seen that no matter the current density is 2mAcm -2 Still 5mAcm -2 , and the cycle efficiency...

Embodiment 2

[0033] With lithium bisfluorosulfonimide as the solute and 1,3-dioxane as the solvent, configure 3.0molL in a glove box protected by an argon atmosphere (water content-1Lithium bisfluorosulfonyl imide / 1,3-dioxane electrolyte, and the Celgard 2400 diaphragm was immersed in the electrolyte, and after 24 hours at room temperature, a gel electrolyte was formed. Then assemble lithium / copper and lithium / lithium button batteries (CR2025) to test the cycle efficiency and cycle stability of the lithium metal anode material, the diameter of the lithium sheet is 12mm, and the diameter of the copper sheet is 18mm. After testing, the gel electrolyte prepared in this example is also similar to Example 1, and has high cycle efficiency and cycle stability.

Embodiment 3

[0035] With lithium bisfluorosulfonyl imide as the solute and 1,3-dioxane as the solvent, configure 4.0molL in a glove box protected by an argon atmosphere (water content-1 Lithium bisfluorosulfonyl imide / 1,3-dioxane electrolyte, and the Celgard 2400 diaphragm was immersed in the electrolyte, and after 24 hours at room temperature, a gel electrolyte was formed. Then assemble lithium / copper and lithium / lithium button batteries (CR2025) to test the cycle efficiency and cycle stability of the lithium metal anode material, the diameter of the lithium sheet is 12mm, and the diameter of the copper sheet is 18mm. After testing, the gel electrolyte prepared in this example is also similar to Example 1, and has high cycle efficiency and cycle stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com