A method of recycling polyimide waste

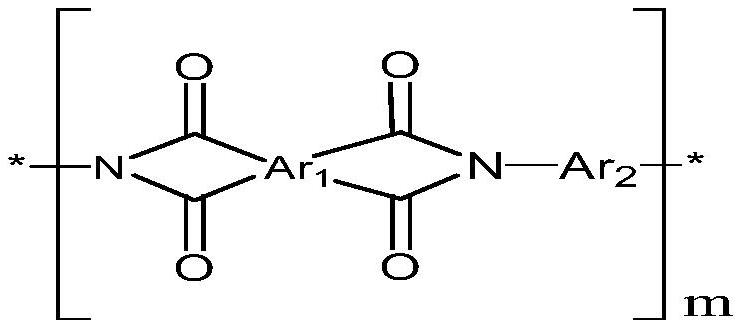

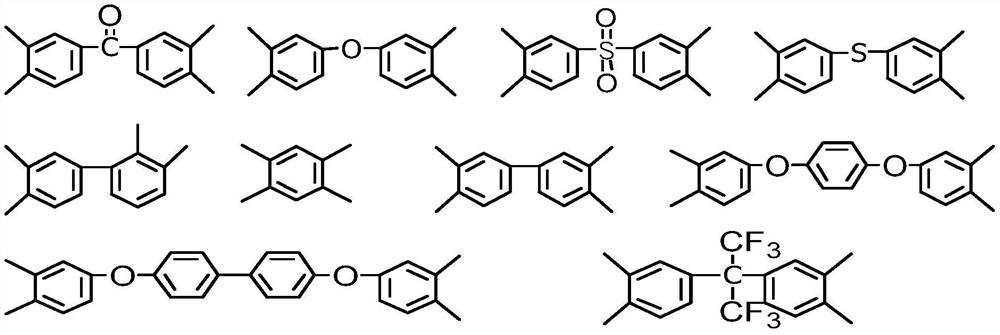

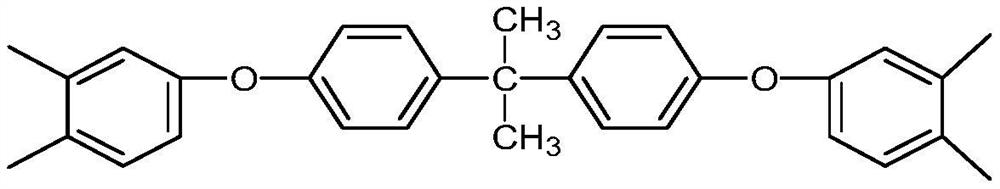

A polyimide and waste technology, applied in the field of recycling polyimide waste, can solve the problems of high hydrolysis requirement of polyimide waste, low monomer yield and purity, etc., and achieve high yield , strong reactivity, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] In a 2L three-necked reaction flask equipped with a spherical reflux condenser and a mechanical stirrer, 100 g of polyimide film fragments (PMDA and ODA) with a pyromellitic dianhydride / 4,4'-diaminodiphenyl ether structure were added. The number of moles is 0.2615mol), after nitrogen replacement, add 80% hydrazine hydrate 150g (3.138mol), PMDA: hydrazine hydrate=1: 12, then be warming up to 85 ℃ and maintain under the condition of nitrogen blanketing, observe reaction phenomenon , when the film fragments disappear and a large amount of white powder is precipitated, take samples and conduct liquid chromatography analysis on the white solid and liquid respectively, and confirm that the hydrazinolysis reaction is completed and the temperature is lowered to below 40°C, and 4,4'-diaminodiphenyl ether is filtered out The crude product was then washed with pure water for 4 times, dried in vacuum and then sublimated with a vacuum sublimator to obtain 51.32 g of 4,4'-diaminodiphe...

Embodiment 2

[0060] Add 100g of polyimide with the structure of 4,4'-diphenyl ether tetra-acid dianhydride / 4,4'-diaminodiphenyl ether into a 2L three-necked reaction flask equipped with a spherical reflux condenser and a mechanical stirrer Powder (the number of moles of ODPA and ODA is 0.2108mol), after nitrogen replacement, add 65% hydrazine hydrate 150g (2.55mol), ODPA: hydrazine hydrate=1: 12, then be warming up to 85 ℃ under the condition of nitrogen blanketing and Maintain and observe the reaction phenomenon. When the film fragments disappear and a large amount of white powder precipitates, take samples and conduct liquid chromatography analysis on the white solid and liquid respectively. After the hydrazinolysis reaction is completed, the temperature is lowered to below 40°C, and 4,4'- The crude diaminodiphenyl ether was washed four times with pure water, dried in vacuum and then sublimated with a vacuum sublimator to obtain 41.79 g of 4,4'-diaminodiphenyl ether with a purity of 99.6%...

Embodiment 3

[0063] Add 100g of polyimide with 4,4'-benzophenonetetraacid dianhydride / 4,4'-diaminodiphenylmethane structure in a 2L three-necked reaction flask equipped with a spherical reflux condenser and a mechanical stirrer Powder (the molar number of BTDA and MDA is 0.2063mol), after nitrogen displacement, add 70% hydrazine hydrate 150g (2.785mol), BTDA: hydrazine hydrate=1: 13.5, be warming up to 100 ℃ under the condition of nitrogen blanketing then and Maintain and observe the reaction phenomenon. When the film fragments disappear and a large amount of white powder precipitates, take samples and conduct liquid chromatography analysis on the white solid and liquid respectively. After the hydrazinolysis reaction is completed, the temperature is lowered to below 40°C, and 4,4'- The crude diaminodiphenylmethane was washed four times with pure water, dried in vacuum and then sublimated with a vacuum sublimator to obtain 40.08 g of 4,4'-diaminodiphenylmethane with a purity of 99.4% and a y...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com