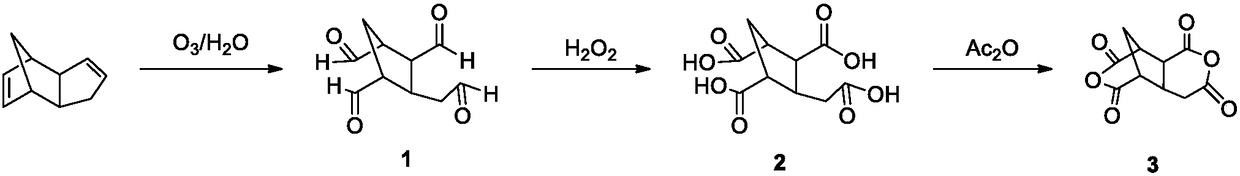

Preparation method of 3-carboxymethyl-1,2,4-cyclopentanetricarboxylic acid-1,4:2,3-dianhydride

A technology of cyclopentanetricarboxylic acid and tricarboxylic acid cyclopentaneacetic acid, applied in the field of fine chemicals, can solve the problems of low product purity, low yield, severe reaction and exothermic operation and runaway operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Put 132.20g (1.00mol) of dicyclopentadiene, 600.00g of methanol solvent, and 150.00g of distilled water in a bubble reactor, and at low temperature, continuously feed ozone gas from the bottom of the bubble reactor to control the reaction temperature After 4 hours of reaction, the raw materials were detected by the gas phase to be completely reacted, and the prepared crude product was directly carried out to the next reaction without any treatment.

[0020] Place the reaction solution of the previous step in a reactor with a fractionation device, add 250.00g (2.20mol) of 30% hydrogen peroxide in batches, control the reaction temperature at 60°C, and extract 400.00g by vacuum distillation during the reaction The solvent was mixed, and the reaction was completed after 8 hours. Distilled under reduced pressure to obtain 244.60 g of a colorless transparent viscous liquid with a yield of 94.10%, which was 2,3,5-tricarboxylic acid cyclopentaneacetic acid.

[0021] Put 244.60g...

Embodiment 2

[0023] Put 132.20g (1.00mol) of dicyclopentadiene, 600.00g of ethanol solvent, and 150.00g of distilled water in the bubble reactor, and at low temperature, continuously feed ozone gas from the bottom of the bubble reactor to control the reaction temperature After 5 hours of reaction, the gas phase detection of the raw material reaction was complete, and the prepared crude product was directly carried out to the next reaction without any treatment.

[0024] Place the reaction solution in the previous step in a reactor with a fractionation device, add 272.00g (2.40mol) of hydrogen peroxide with a concentration of 30% in batches, control the reaction temperature at 80°C, and extract 400.00g by vacuum distillation during the reaction The solvent was mixed, and the reaction was completed after 7 hours. Distilled under reduced pressure to obtain 241.20 g of a colorless transparent viscous liquid with a yield of 92.70%, which was 2,3,5-tricarboxylic acid cyclopentaneacetic acid.

[...

Embodiment 3

[0027] Place 132.20g (1.00mol) of dicyclopentadiene, 600g formic acid solvent, and 150g distilled water in a bubble reactor, and at low temperature, continuously feed ozone gas from the bottom of the bubble reactor to control the reaction temperature to 0 ℃, after 6 hours of reaction, the gas phase detection of the raw material reaction was complete, and the prepared crude product was directly carried out to the next reaction without any treatment.

[0028] Place the reaction solution in the previous step in a reactor with a fractionation device, add 295.00g (2.60mol) of 30% hydrogen peroxide in batches, control the reaction temperature to 100°C, and extract 400.00g by vacuum distillation during the reaction The solvent was mixed, and the reaction was completed after 5 hours. Distilled under reduced pressure to obtain 234.80 g of light yellow transparent viscous liquid with a yield of 90.24%, which was 2,3,5-tricarboxylic acid cyclopentaneacetic acid.

[0029] Put 234.80g (0.9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com