Method for adsorbing CO2 in gases

A CO2, gas technology, applied in the field of CO2 adsorption in gas, can solve the problems of low thermal stability, unsatisfactory CO2 removal degree, complicated preparation process of adsorbent, etc., achieving low cost, increased crystallinity, diffusion Low resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

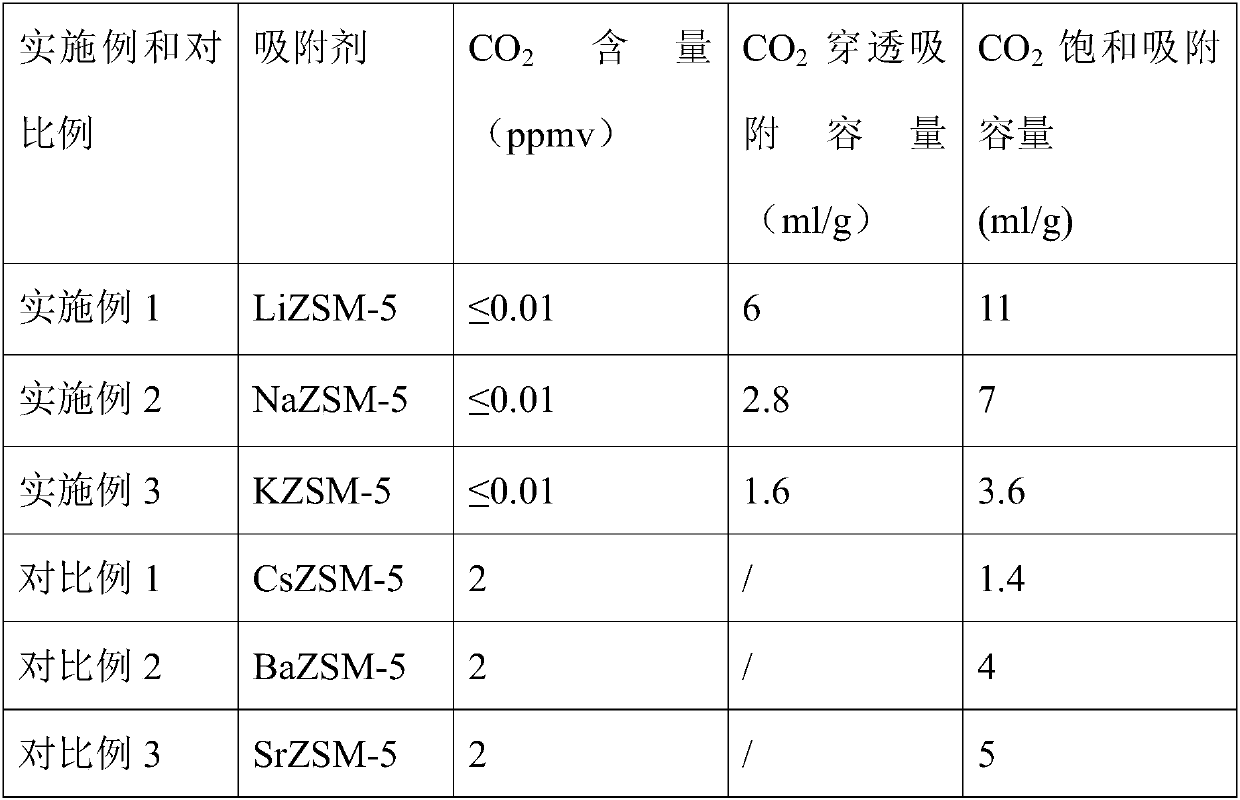

Embodiment 1-3 and comparative example 1-3

[0022] Embodiment 1-3 of the present invention all adopts the following method to low concentration CO in the gas 2 The adsorption process includes the following steps: fill 10g of adsorbent in the middle of a stainless steel tube with an inner diameter of 20mm and a length of 400mm, and fill the rest with ceramic sheets. -1 N 2 Activate in air for 5h, then lower the temperature to 25°C, under normal pressure, take 100h -1 Space velocity, from the top of the adsorption fixed bed into the low concentration of CO containing 1000ppmv 2 The gas after adsorption is analyzed by gas chromatography with a helium ion detector for CO 2 content until the adsorption reaches saturation. CO 2 When the content reaches 1ppmv, it is the breakthrough point, and the adsorption effect of the adsorbent on CO 2 breakthrough adsorption capacity and saturated adsorption capacity.

[0023] The other conditions of Comparative Examples 1-3 are the same as those of Examples 1-3, except that the ads...

Embodiment 4-7

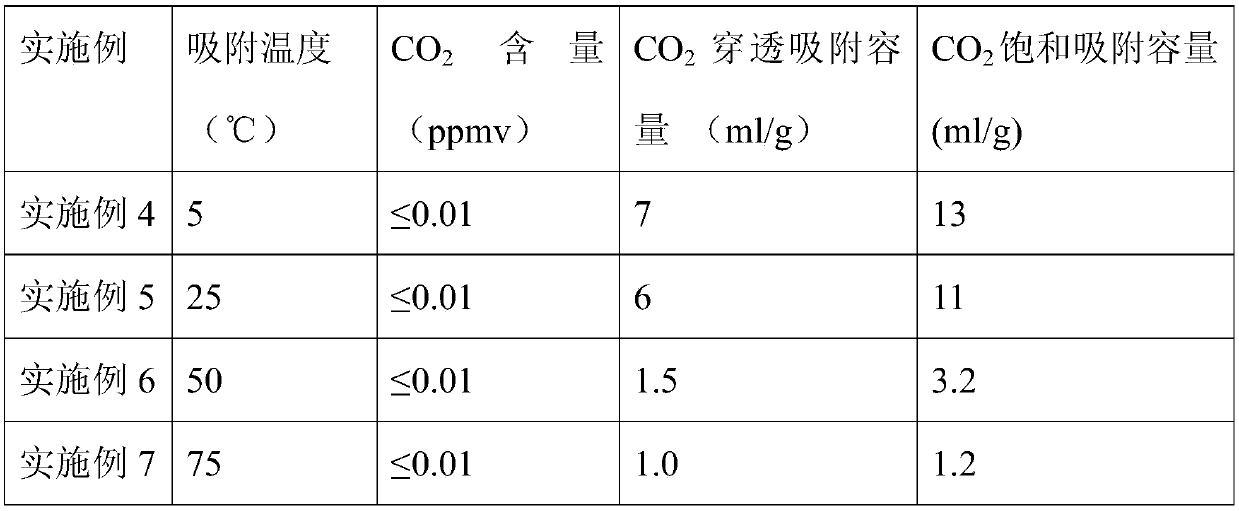

[0028] The other conditions of Examples 4-7 are the same as those of Examples 1-3, except that the adsorbent is changed to LiZSM-5 molecular sieve, and the adsorption temperatures are 5°C, 25°C, 50°C and 75°C respectively. The results are shown in Table 2.

[0029] Table 2 Adsorption temperature of CO adsorption on LiZSM-5 molecular sieve 2 performance impact

[0030]

[0031] It can be seen from Examples 4-7 that with the increase of adsorption temperature, CO 2 breakthrough adsorption capacity and CO 2 The saturation adsorption capacity was significantly reduced, so it can be seen that the increase of adsorption temperature greatly reduces the CO 2 breakthrough adsorption capacity and CO 2 Saturated adsorption capacity is not conducive to the maximization of the adsorption performance of the adsorbent. It can be seen from Examples 4-7 that when the adsorption temperature in Example 4 is 5 °C, CO 2 breakthrough adsorption capacity and CO 2 The saturated adsorption cap...

Embodiment 8-10

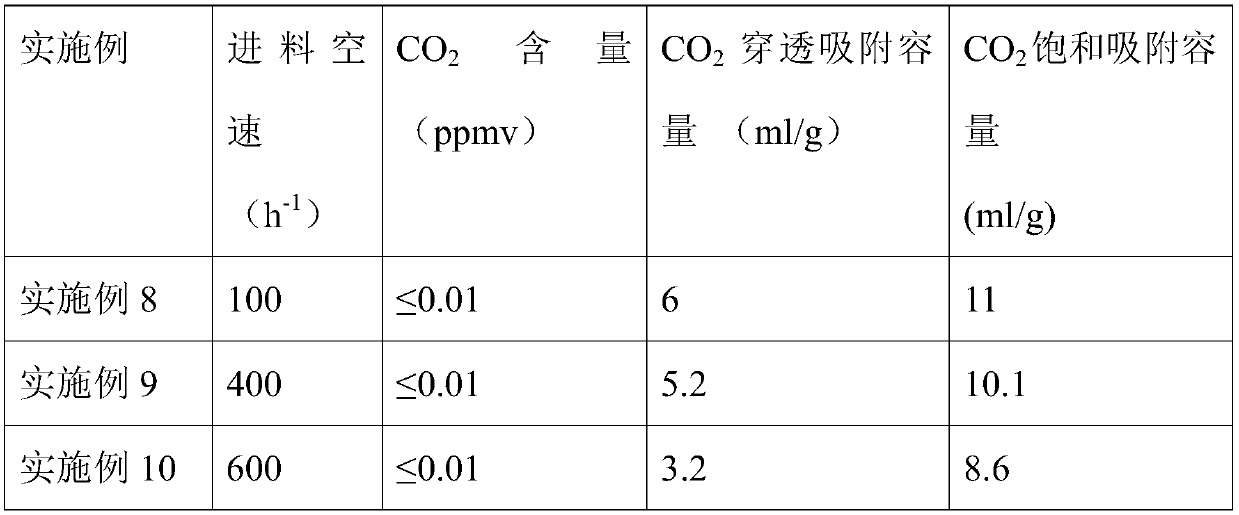

[0033] Other conditions of embodiment 8-10 are the same as embodiment 1-3, only the adsorbent is changed to LiZSM-5 molecular sieve, N 2 / CO 2 Mixed gas feed space velocity is 100h -1 , 400h -1 ,600h -1 , the results are shown in Table 3.

[0034] Table 3 Feed space velocity on CO adsorption by LiZSM-5 molecular sieve 2 performance impact

[0035]

[0036] As can be seen from Examples 8-10, with N 2 / CO 2 The increase of the mixed gas feed space velocity, CO 2 breakthrough adsorption capacity and CO 2 The saturated adsorption capacity decreases accordingly, and in Example 8, N 2 / CO 2 The mixed gas feed space velocity is 100 -1 , when CO 2 The breakthrough adsorption capacity and CO2 saturation adsorption capacity are the largest, and LiZSM-5 molecular sieve adsorbs CO 2 The best performance, the injection space velocity is too fast will cause CO 2 The contact time with the molecular sieve is reduced, thereby reducing the adsorption efficiency and quality, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com