Preparation method of fluorine-containing cyanate monomer

A technology of fluorine-containing cyanate and monomer, which is applied in the field of preparation of fluorine-containing cyanate monomer, and can solve problems such as unsatisfactory mechanical properties and poor dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Put a 3000mL four-necked bottle in an ice-salt bath, add 450mL of acetone and 65g of cyanogen chloride, and stir to completely dissolve the cyanogen chloride.

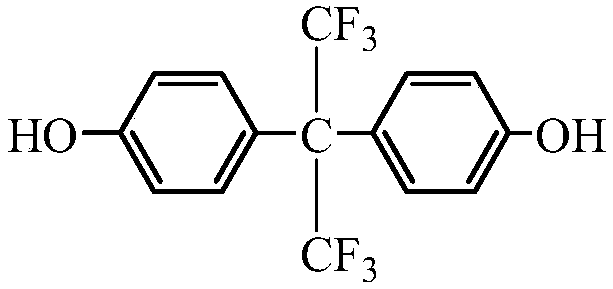

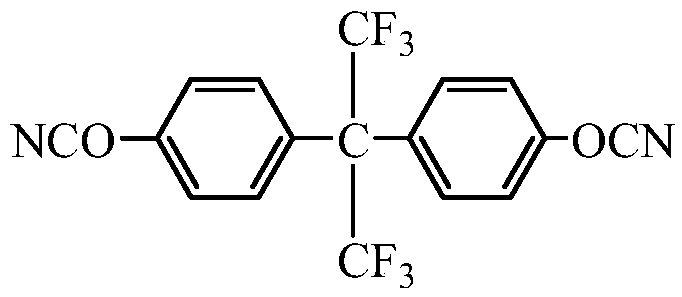

[0022] (2) Under vigorous stirring, slowly add the solution of 101g triethylamine and 156g bisphenol AF, pay attention to make the drop rate of triethylamine slightly slower than that of bisphenol AF, and control the reaction temperature at -20°C-0 ℃, about 4h after the dropwise addition is complete, and then continue to stir for 3h to stop the reaction.

[0023] (3) Filter after standing for 2 hours to obtain the crude product of bisphenol AF type cyanate resin with a yield of 95%.

[0024] (4) Dissolve the crude product with dichloromethane, filter and distill, wash and filter with 2% sodium hydroxide solution, and wash the obtained product three times with deionized water. Dissolve the resin with dichloromethane, let it stand for a week, and dry the precipitated crystals with magnesium sulfate to obtain ...

Embodiment 2

[0028] (1) Put a 3000mL four-necked bottle in an ice-salt bath, add 450mL of acetone and 116.6 cyanogen bromide, and stir to completely dissolve the cyanogen bromide.

[0029] (2) Under vigorous stirring, slowly drop a solution of 101g triethylamine and 168g bisphenol AF, pay attention to make the drop rate of triethylamine slightly slower than that of bisphenol AF, and control the reaction temperature at -20-0°C , After about 4h, the dropwise addition was completed, and then continued to stir for 3h to stop the reaction.

[0030] (3) Filter after standing for 2 hours to obtain the crude product of bisphenol AF type cyanate resin with a yield of 96%.

[0031] (4) Dissolve the crude product with dichloromethane, filter and distill, wash and filter with 2% sodium hydroxide solution, and wash the obtained product three times with deionized water. Dissolve the resin with dichloromethane, let it stand for a week, and dry the precipitated crystals with magnesium sulfate to obtain a...

Embodiment 3

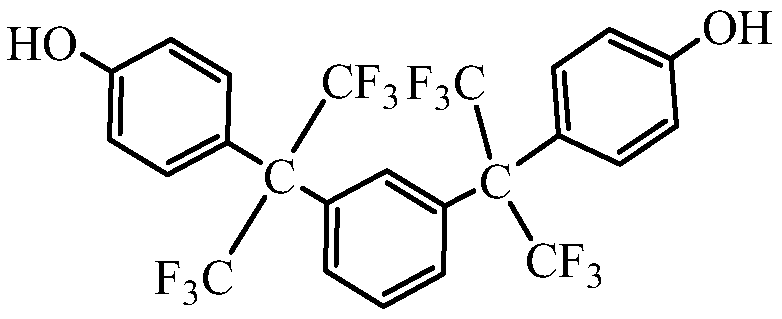

[0035] (1) Put a 3000ml four-neck flask in an ice-salt bath, add 900mL of acetone and 222.6g of cyanogen bromide, and stir to completely dissolve the cyanogen bromide.

[0036] (2) Under vigorous stirring, slowly add a solution of 202g triethylamine and 336g 1,3-bis[2-(4-hydroxyphenyl)hexafluoroisopropyl]benzene, paying attention to the rate of addition of triethylamine Slightly slower than the drop rate of 1,3-bis[2-(4-hydroxyphenyl)hexafluoroisopropyl]benzene, control the reaction temperature at -20-0°C, complete the drop after about 6 hours, and then continue to stir for 3 hours , stop responding.

[0037] (3) After standing for 2 hours, it was filtered to obtain the crude product of 1,3-bis[2-(4-hydroxyphenyl)hexafluoroisopropyl]benzene-type cyanate resin with a yield of 90%.

[0038] (4) Dissolve the crude product with dichloromethane, filter and distill, wash and filter with 3% sodium hydroxide solution, and wash the obtained product three times with deionized water. D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com