Production process of heparin sodium in porcine small intestine mucosa

A production process and heparin sodium technology, applied in the field of heparin sodium production technology, can solve problems such as increasing the processing difficulty of enzymatic hydrolysis solution adsorption and elution, increasing the environmental protection cost of sewage treatment, affecting the quality and purity of heparin sodium, etc., so as to save environmental protection. The effect of process, short adsorption time and thorough adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The heparin sodium production process of pig small intestine mucosa of the present invention comprises the following steps:

[0032] S1. Enzymolysis: Add the intestinal mucosa into the enzymolysis tank, add salt and stir for 10 minutes, then heat to 40-45°C, stop heating and stir for 10 minutes, adjust the pH value to 7.2-7.5 with sodium hydroxide, and stir for another 10 minutes Finally, add 2709 protease, stir for another ten minutes, then heat to 56-58°C, continue to stir for 30 minutes, then stop stirring and keep warm for 2 hours. -92°C, then keep warm for 30-60 minutes until the liquid in the enzymolysis tank is separated, the upper layer is protein, and the lower layer is clarified enzymolysis solution, separate the protein and enzymolysis solution, collect the enzymolysis solution and filter;

[0033] S2. Adsorption: After filtering the protein solution in the enzymolysis solution collected in step S1 by manger filtration, use clean water to reduce the temperatu...

Embodiment 2

[0042] Based on Example 1, the enzymatic hydrolysis in step S1 includes the following steps: adding the intestinal mucosa into an enzymatic hydrolysis tank, adding 3.5% of the intestinal mucosa weight and stirring for 10 minutes, then directly steaming and heating to 45°C, stopping the heating and stirring for 10 minutes Minutes, adjust the pH value to 7.2-7.5 with sodium hydroxide, stir for another 10 minutes, add 2709 protease, stir for another ten minutes, steam directly to 58 ° C, continue stirring for 30 minutes, stop stirring and keep warm for 2 hours, keep warm for 2 hours Finally, use steam direct heating and steam coil heating to quickly heat up to 85°C, turn off steam direct heating after the temperature rises to 85°C, use steam coil heating to slowly heat to 92°C, and then keep warm for 60 minutes to wait for the enzyme The liquid in the hydrolysis tank is layered, the upper layer is protein, and the lower layer is clarified enzymolysis solution, the protein and enzy...

Embodiment 3

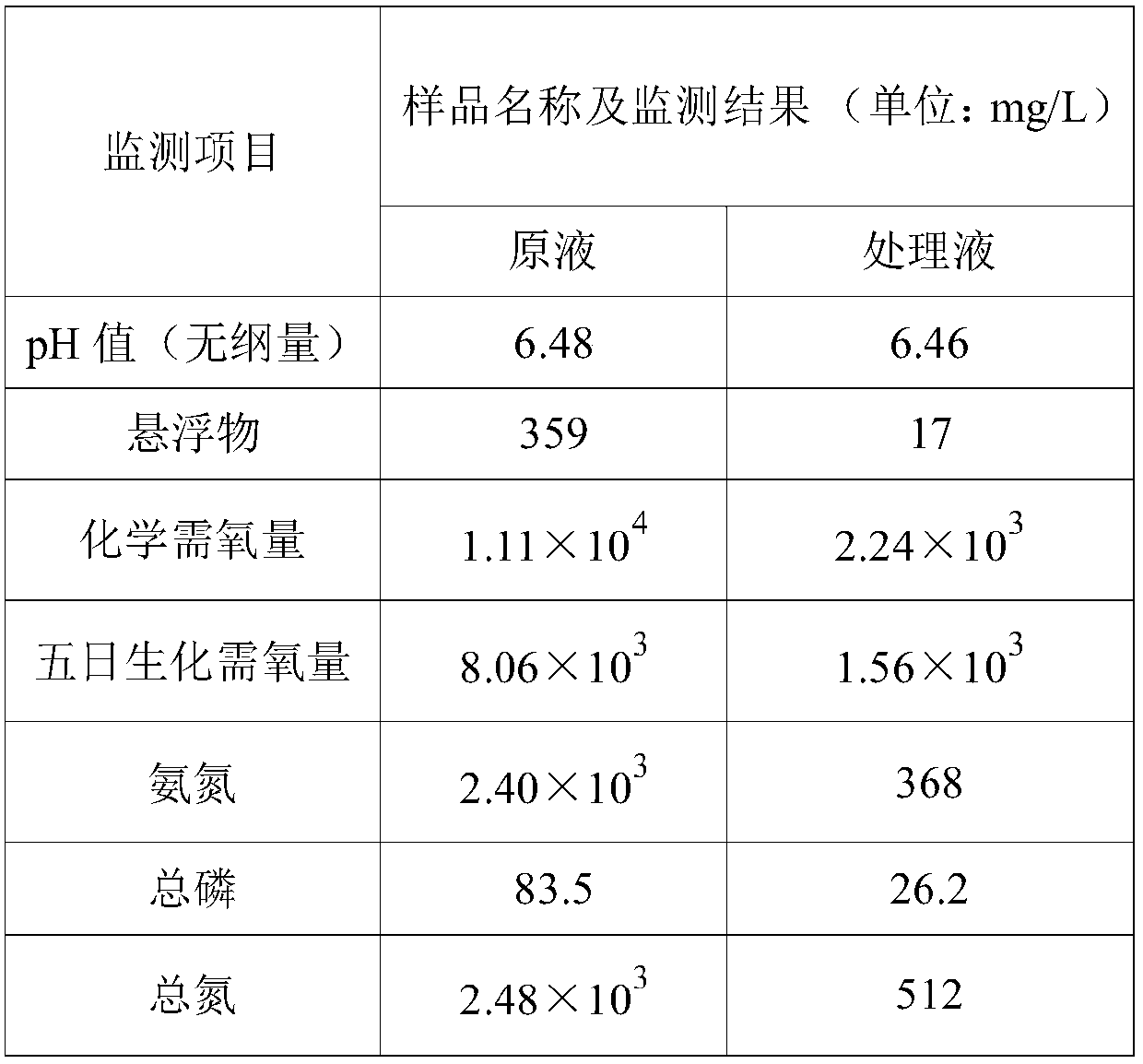

[0044] The enzymolysis solution produced according to the enzymolysis method described in Example 2 is subjected to membrane filtration to obtain a treatment solution, and the components of the treatment solution and the unfiltered stock solution are detected. The unfiltered stock solution refers to the method described in Example 2. The enzymatic hydrolyzate produced by the enzymatic hydrolysis method, the test results are as follows:

[0045]

[0046] Conclusion: each index in the enzymolysis solution produced by the enzymolysis method of Example 2 of the present invention is better than that of the enzymolysis solution produced by the traditional method. In summary, it can be clearly seen that the enzymolysis solution produced by the present invention is clean and environmentally friendly, and contains The amount of protein and other impurities is small, and all the indicators of the treatment liquid after membrane filtration can reach the environmental protection value, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com