High temperature and high pressure-resistant type graphene-modified phenolic heavy-duty anti-corrosive coating for oil pipe

A graphene-modified, high-temperature-resistant technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of high coating thickness and compactness requirements, increased cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

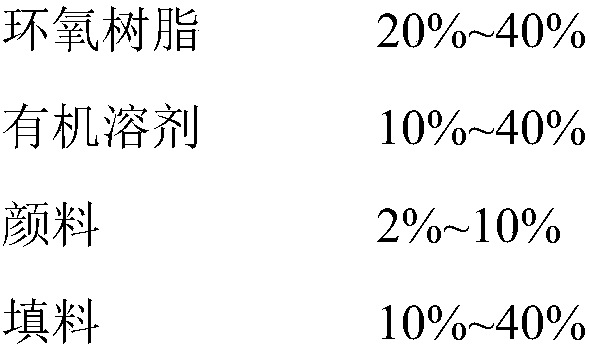

[0049] The raw material composition of anti-corrosion coating primer is as follows:

[0050] Primer A component: novolak epoxy resin (DEH431) 24%, bisphenol A epoxy resin (E20) 11%, xylene 10%, n-butanol 6%, cyclohexanone 1%, 1,4- Butanediol diglycidyl ether 1%, mica iron oxide 8%, talcum powder 8%, mica 15%, zinc phosphate 5%, wax powder 2%, iron oxide red powder 8%, additives 1%;

[0051] Among them, additives include wetting and dispersing agent (BYK163) 0.3%, silane coupling agent (560) 0.3%, adhesion additive (BYK4510) 0.2%, defoamer (BYK066) 0.1%, leveling agent (BYK310) 0.1% %;

[0052] Primer B component: epoxy curing agent, accounting for 8% of the mass of primer A component, specifically, aromatic amine curing agent (4702): modified alicyclic amine curing agent (2280) = 1:1.

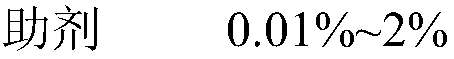

[0053] Anti-corrosion paint topcoat raw materials are composed of:

[0054]Topcoat A component: novolac epoxy resin (DEH431) 40%, xylene 10%, n-butanol 6%, cyclohexanone 3%, 1,4-butanediol d...

Embodiment 2

[0058] The raw material composition of anti-corrosion coating primer is as follows:

[0059] Primer A component: novolak epoxy resin (DEH431) 24%, bisphenol A epoxy resin (E20) 11%, xylene 10%, n-butanol 6%, cyclohexanone 1%, 1,4- Butanediol diglycidyl ether 1%, mica iron oxide 8%, talcum powder 8%, mica 15%, zinc phosphate 5%, wax powder 2%, iron oxide red powder 8%, additives 1%;

[0060] Among them, additives include wetting and dispersing agent (BYK163) 0.3%, silane coupling agent (560) 0.3%, adhesion additive (BYK4510) 0.2%, defoamer (BYK066) 0.1%, leveling agent (BYK310) 0.1% %.

[0061] Primer B component: epoxy curing agent, accounting for 8% of the mass of primer A component, specifically, aromatic amine curing agent (4702): modified alicyclic amine curing agent (2280) = 1:1.

[0062] Anti-corrosion paint topcoat raw materials are composed of:

[0063] Topcoat A component: novolac epoxy resin (DEH431) 40%, xylene 10%, n-butanol 6%, cyclohexanone 3%, 1,4-butanediol ...

Embodiment 3

[0069] The raw material composition of anti-corrosion coating primer is as follows:

[0070] Primer A component: novolac epoxy resin (DEH431) 24%, bisphenol A epoxy resin (E20) 11%, xylene 10%, n-butanol 6%, cyclohexanone 1%, 1,4- Butanediol diglycidyl ether 1%, mica iron oxide 8%, talc powder 8%, mica 15%, zinc phosphate 5%, wax powder 1.5%, iron oxide red powder 8%, additives 1.5%;

[0071] Among them, additives include wetting and dispersing agent (BYK163) 0.3%, silane coupling agent (560) 0.3%, adhesion additive (BYK4510) 0.3%, defoamer (BYK066) 0.3%, leveling agent (BYK310) 0.3% %.

[0072] Primer B component: epoxy curing agent, accounting for 8% of the mass of primer A component, specifically, aromatic amine curing agent (4702): modified alicyclic amine curing agent (2280) = 1:1.

[0073] Anti-corrosion paint topcoat raw materials are composed of:

[0074] Topcoat A component: novolac epoxy resin (DEH431) 40%, xylene 10%, n-butanol 6%, cyclohexanone 3%, 1,4-butanedio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com