Nano-aerogel modified bi-component ceramic tile backing adhesive as well preparation method and use method thereof

A nano-airgel, two-component technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem of limited bond strength of vitrified tiles, falling off of vitrified tiles, and inability to effectively solve the problem of sticking The problem of large stress in the brick layer can be solved to solve the problem of easy hollowing and falling off and improve the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

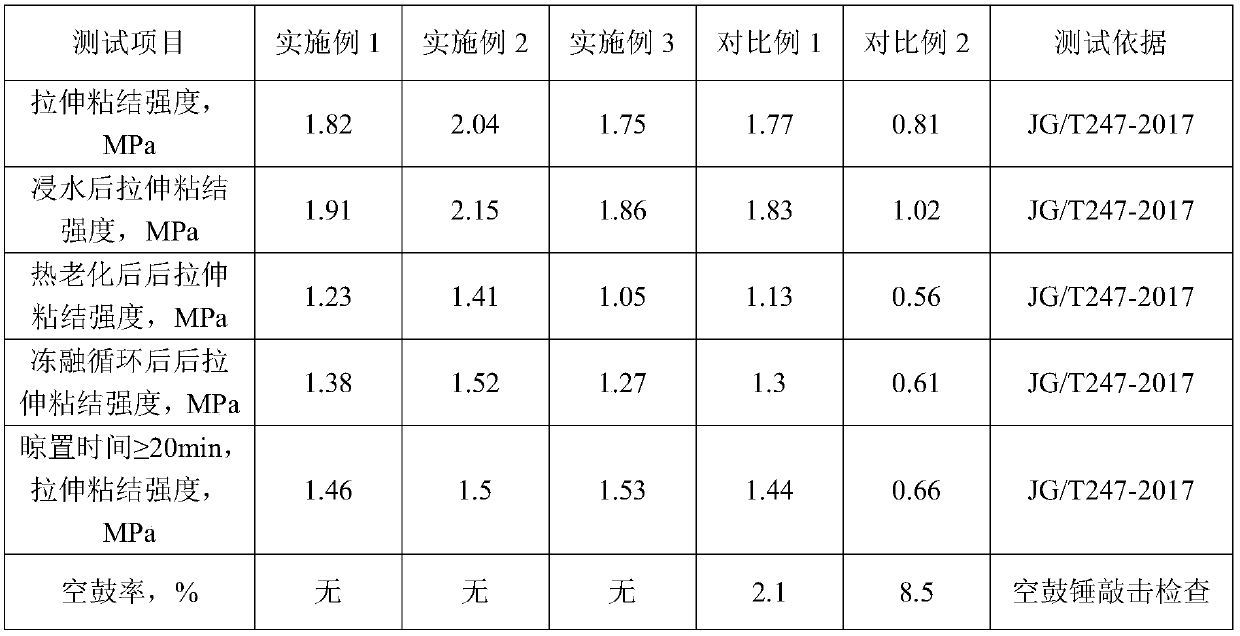

Examples

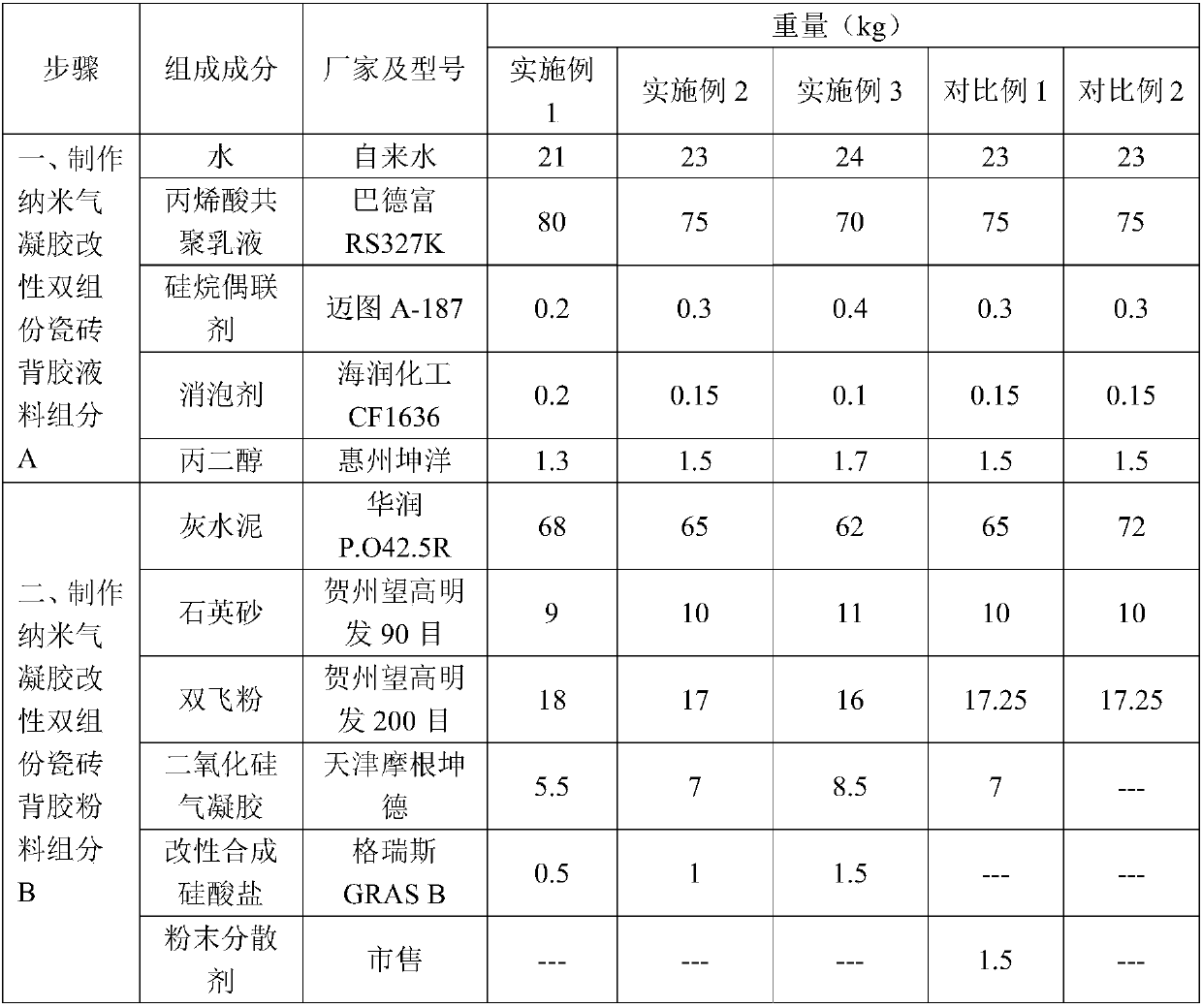

Embodiment 1

[0041] Step 1. Preparation of component A:

[0042] Add 21kg of tap water and 80kg of acrylate copolymer emulsion into the pre-dispersion tank, start stirring, then add 0.2kg of silane coupling agent, 0.2kg of defoaming agent, and 1.3kg of propylene glycol in turn under stirring at 400-500 rpm. Stir and mix for 15 minutes at 500-700 rpm, filter and pack through a 100-mesh filter, and set aside.

[0043] Step 2, preparation of component B:

[0044] Add 68kg of gray cement, 9kg of quartz sand, 18kg of Shuangfei powder, 5.5kg of nano-silica airgel, and 0.5kg of modified synthetic silicate into the production tank, and then stir for 25 ~30min until uniform. Measured and packaged by a fully automatic packaging machine, ready for use.

[0045] Step 3. Prepare nano-airgel modified two-component tile adhesive:

[0046] According to the ratio of component A: component B = 1:1. Add the powder of component B into the liquid material of component A under stirring and stir well.

[0...

Embodiment 2

[0050] Step 1. Preparation of component A:

[0051] Add 23kg of tap water and 75kg of acrylate copolymer emulsion into the pre-dispersion tank, start stirring, and then add 0.3kg of silane coupling agent, 0.15kg of defoamer, and 1.5kg of propylene glycol in turn under stirring at a speed of 400 to 500 rpm. Stir and mix for 15 minutes at 500-700 rpm, filter and pack through a 100-mesh filter, and set aside.

[0052] Step 2, preparation of component B:

[0053] Add 65kg of gray cement, 10kg of quartz sand, 17kg of Shuangfei powder, 7kg of nano-silica airgel, and 1kg of modified synthetic silicate into the production tank in sequence, and then stir for 25-30 minutes at a speed of 35-45 rpm , to uniformity. Measured and packaged by a fully automatic packaging machine, ready for use.

[0054] Step 3. Prepare nano-airgel modified two-component tile adhesive:

[0055] According to the ratio of component A: component B = 1:1. Add the powder of component B into the liquid material...

Embodiment 3

[0059] Step 1. Preparation of component A:

[0060] Add 24kg of tap water and 70kg of acrylate copolymer emulsion into the pre-dispersion tank, start stirring, and then add 0.4kg of silane coupling agent, 0.1kg of defoamer, and 1.7kg of propylene glycol in sequence under stirring at a speed of 400 to 500 rpm. Stir and mix for 15 minutes at 500-700 rpm, filter and pack through a 100-mesh filter, and set aside.

[0061] Step 2, preparation of component B:

[0062] Add 62kg of gray cement, 11kg of quartz sand, 16kg of Shuangfei powder, 8.5kg of nano-silica airgel, and 1.5kg of modified synthetic silicate into the production tank, and then stir for 25 ~30min until uniform. Measured and packaged by a fully automatic packaging machine, ready for use.

[0063] Step 3. Prepare nano-airgel modified two-component tile adhesive:

[0064] According to the ratio of component A: component B = 1:1. Add the powder of component B into the liquid material of component A under stirring and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com