Method for preparing chromium curing/stabilizing material, chromium curing/stabilizing material prepared thereby and application thereof

A stabilization and stabilizer technology, applied in the field of deep processing of mineral materials, can solve the problems of unreasonable storage and disposal of chromium slag, soil and groundwater pollution, etc., and achieve the effect of lasting and stable curing effect, difficult to analyze and simple maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: Preparation of chromium curing / stabilizing material

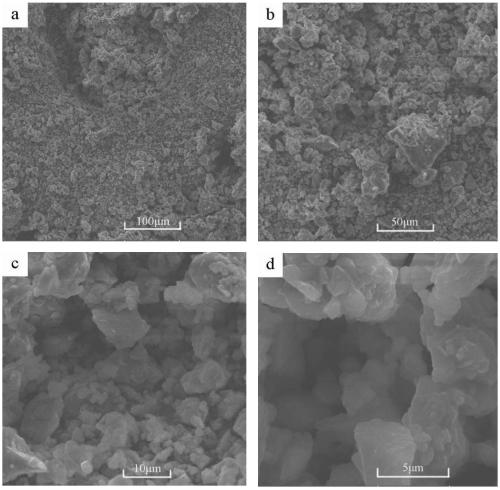

[0045] Mix 1000g of biotite, 2000g of dolomite, and 80g of sodium carbonate, grind it to below 200 mesh, roast at 1200°C for 1.5h, and obtain 2116g of calcined material after cooling. Gained calcined material SEM photo, the result is as follows figure 1 As shown, (a) is a photo enlarged by 464 times, (b) is a photo enlarged by 977 times, (c) is a photo enlarged by 3910 times, and (d) is a photo enlarged by 12300 times. Depend onfigure 1 As shown, the calcined material has nanoscale micropores and interlayer structure.

[0046] After testing, in the calcined material, with SiO 2 The citric acid soluble silicon is 30.17wt%, the calcium and magnesium content is 47.93wt% in CaO, the CEC capacity is 61.29cmol / kg, and the specific surface area is 136m 2 / g.

[0047] Add 160g of sodium fluorosilicate, 800g of ferrous sulfate, and 160g of sodium phosphate to the roasted material obtained above and grind it ...

Embodiment 2

[0048] Embodiment two: remediation of chromium-contaminated soil

[0049] The chromium-contaminated soil remediation test was carried out using the chromium solidification / stabilization material prepared in Example 1 as a remediation agent.

[0050] Test object:

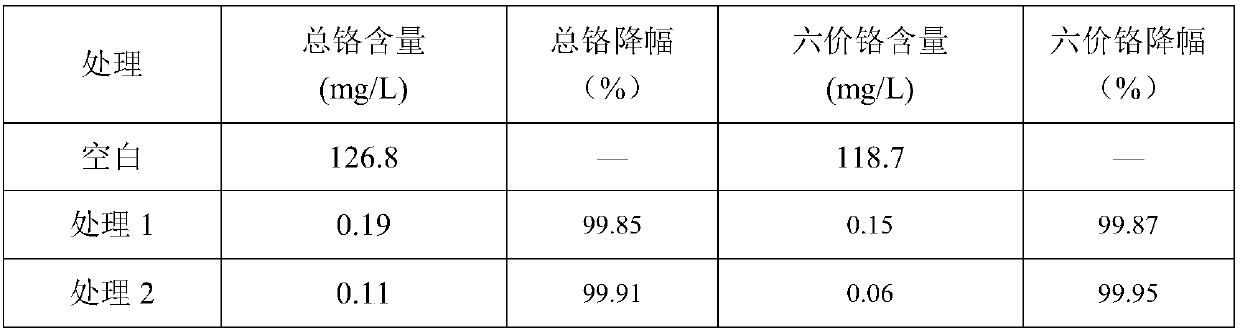

[0051] Taking chromium-contaminated soil in a town of Liuyang City, Changsha City as the test object, the total chromium content in the soil is 1326mg / kg, and the hexavalent chromium content is 1183mg / kg.

[0052] experiment method:

[0053] Take 1 kg of polluted soil after air-drying and passing through a 20-mesh sieve in a beaker, and add the chromium solidification prepared in Example 1 according to the ratio of 0g / kg (blank), 65g / kg (treatment 1), and 95g / kg (treatment 2) respectively. / Stabilize the material and stir it well, add phosphoric acid aqueous solution (pH regulator) to adjust the pH value to 6-9 while keeping the soil moisture content at about 30%, transfer the material to a 2L beaker for curing. ...

Embodiment 3

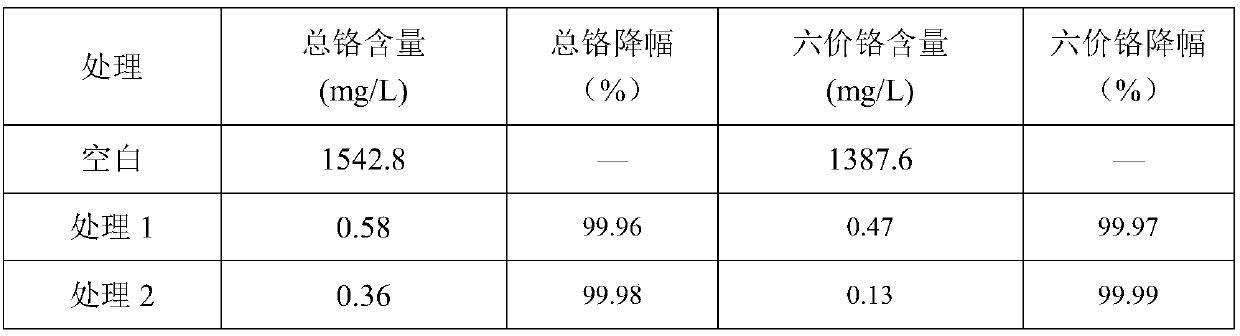

[0056] Embodiment 3: Preparation of chrome curing / stabilizing material

[0057] Mix 1000g of chlorite with 1200g of magnesite and 60g of sodium sulfate, grind it to below 200 mesh, roast at 1280°C for 2 hours, and obtain 1986g of roasted material after cooling. After testing, in the calcined material, with SiO 2 The citric acid soluble silicon is 39.16wt%, the calcium and magnesium content is 42.30wt% in CaO, the CEC capacity is 53.17cmol / kg, and the specific surface area is 127m 2 / g.

[0058] Add 100g of sodium silicate, 1500g of ferrous chloride, and 280g of potassium hydrogen phosphate to the resulting calcined material and mix and grind to pass through a 200-mesh sieve to obtain 3860g of chromium solidified / stabilized material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com