A kind of fiber optic cable strengthening core and preparation method thereof

A fiber optic cable strengthening core and hexagonal boron nitride technology, which is applied in the field of optical cables, can solve the problems of affecting the normal transmission of optical cable information, easy damage, and poor toughness of the optical cable strengthening core.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

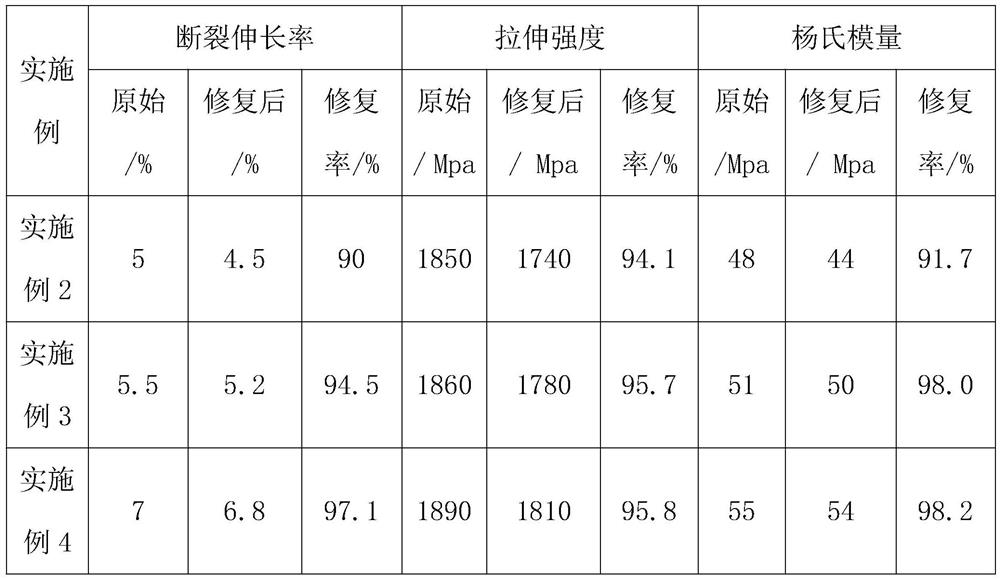

Examples

Embodiment 1

[0026] An optical cable strengthening core, which is obtained by curing and compounding resin coating liquid and aramid fiber, wherein the organic resin coating liquid raw materials include: hydroxylated nano-boron nitride, isocyanate group-terminated water-based polyurethane prepolymer, Bismaleimide, solvent, catalyst, and mold release agent; wherein, the hydroxylated nano-boron nitride contains furan functional groups;

[0027] The preparation method of the fiber optic cable reinforcing core comprises the following steps: preheating the aramid fiber at 180-220° C. for 2-5 minutes, then dipping the resin coating solution, heating and curing the fiber optic cable reinforcing core through a forming mold.

Embodiment 2

[0029] An optical cable strengthening core, which is obtained by curing and compounding a resin coating solution and aramid fibers, wherein the raw materials of the organic resin coating solution include: 3 parts of hydroxylated nano-boron nitride, 30 parts of isocyanate group-terminated water-based polyurethane Prepolymer, 10 parts of N,N'-(1,4-phenylene) bismaleimide, 10 parts of acetone, 0.2 parts of bicyclic guanidine, 1 part of release agent; wherein, hydroxylated nano-boron nitride is composed of 2,5-furandimethanol and hexagonal boron nitride powder are modified by wet ball milling. The specific steps are: mix hexagonal boron nitride powder, 2,5-furandimethanol and water evenly, and ball mill for 5 hours to obtain hydroxylated nano-nitrogen Boron oxide; the weight ratio of hexagonal boron nitride powder, 2,5-furandimethanol, and water is 1:3:20; the ball-to-material ratio is 30:1;

[0030] The specific preparation process of the isocyanate group-terminated waterborne po...

Embodiment 3

[0034] An optical cable strengthening core, which is obtained by curing and compounding resin coating liquid and aramid fiber, wherein the organic resin coating liquid raw materials include: 8 parts of hydroxylated nano-boron nitride, 40 parts of isocyanate group-terminated water-based polyurethane Prepolymer, 5 parts of 4,4'bismaleimidodiphenylmethane, 15 parts of acetone, 0.5 parts of organotin, 2 parts of release agent; among them, hydroxylated nano-boron nitride is composed of 2,5-furan diphenyl Methanol and hexagonal boron nitride powder are modified by wet ball milling. The specific steps are: mix hexagonal boron nitride powder, 2,5-furandimethanol and water evenly, and ball mill for 10 hours to obtain hydroxylated nano boron nitride; hexagonal boron nitride The weight ratio of boron powder, 2,5-furandimethanol and water is 5:8:40; the ball-to-material ratio is 50:1;

[0035] The specific preparation process of the isocyanate group-terminated waterborne polyurethane prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com