Accurate self-preheating type safety energy-saving heat storage combustion system and method

A regenerative combustion and self-preheating technology, applied in the direction of combustion method, burner, combustion type, etc., can solve the problems of insufficient utilization of flue gas, difficulties in high-grade electric energy of combustion technology, and heat loss of flue gas, so as to improve energy Utilization efficiency, providing energy utilization, and reducing heat emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

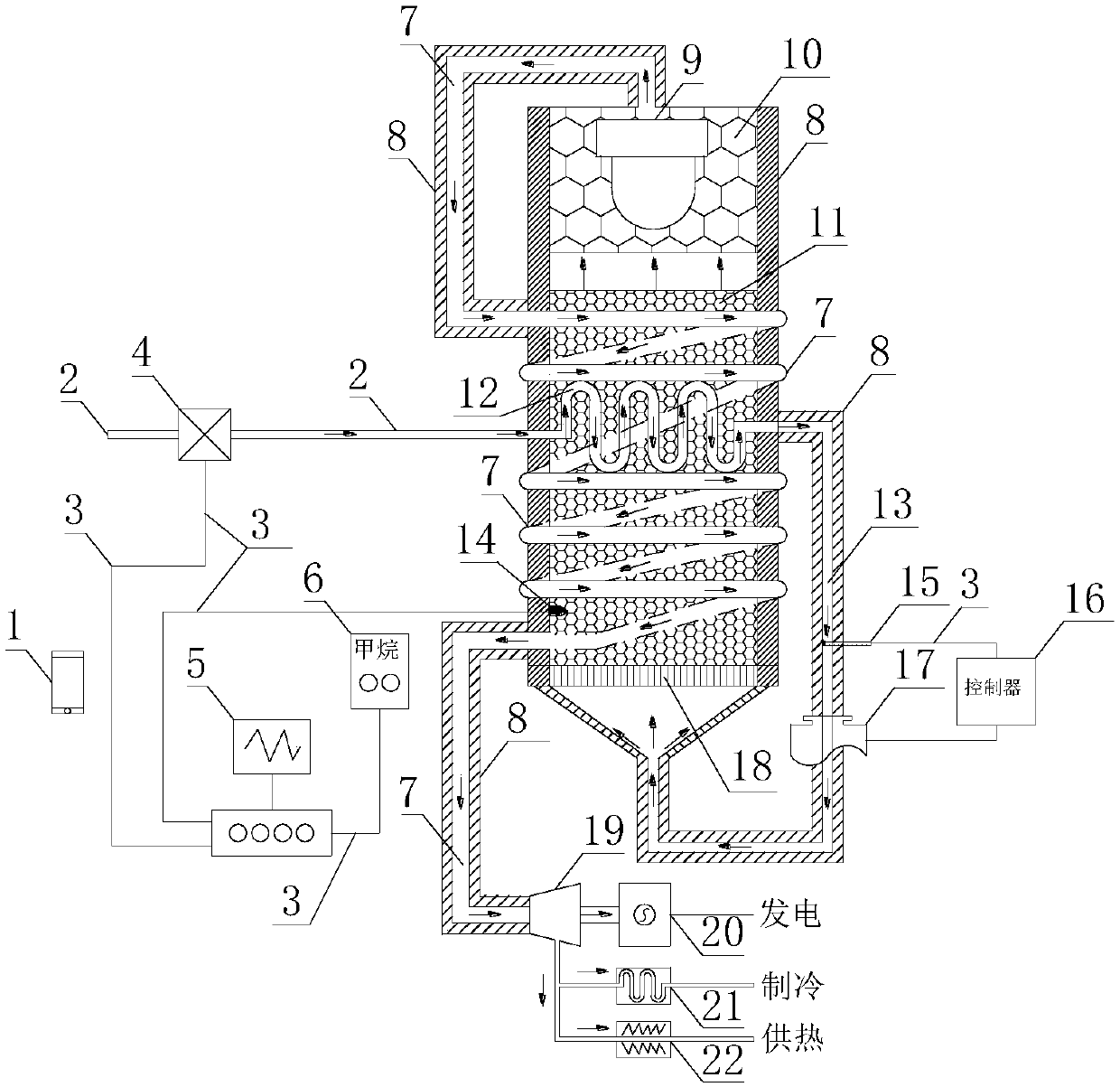

[0038] This embodiment provides a precise self-preheating, safe and energy-saving regenerative combustion system, including a porous media burner, a Stirling generator, an intake pipe, an exhaust pipe, and a heat, electricity, and cooling triple generation system;

[0039] A gas preheating device is provided between the air intake pipe and the porous media burner, and the gas preheating device includes a heat exchange pipe, a preheat pipe, a thermometer and an external heat engine, and the air intake pipe, heat exchange pipe, and preheat pipe are connected in sequence , the heat exchange tube is arranged in the middle of the porous burner, the intake pipe and the preheating pipe are arranged outside the porous burner, and the thermometer is arranged on the preheating pipe at the front end of the external heat engine to detect the temperature of the gas before passing through the external heat engine, The tail end of the preheating tube is connected to the bottom end of the poro...

Embodiment 2

[0043] The precise self-preheating safe and energy-saving regenerative combustion system provided in Example 2 is an optimization scheme based on Example 1. The precise self-preheating safe and energy-saving regenerative combustion system provided in Example 2 also includes A gas monitoring system, the gas monitoring system includes a wireless intelligent terminal, a control valve connected to the intake pipe and a computer, the control valve is connected to the first port of the computer through a signal line, and the igniter is connected to the second port of the computer through a signal line , the igniter is arranged at the lower part of the porous medium combustion gas, the methane sensor is connected to the third port of the computer through a signal line, and the wireless intelligent terminal is connected to the computer in communication.

[0044] The precise self-preheating, safe and energy-saving regenerative combustion system provided in Example 2 can not only use coa...

Embodiment 3

[0046] The precise self-preheating, safe and energy-saving regenerative combustion system provided in Example 3 is an optimization scheme based on Example 1 or Example 2. The precise self-preheating and energy-saving regenerative combustion system provided in Example 3 The system wherein the combined heat, electricity and cooling system includes a steam power machine, a generator connected to the right end of the steam power machine, an absorption refrigerator and a heat exchanger connected to the lower end of the steam power machine.

[0047] The outer layer of the porous media burner and the preheating pipe is covered with a heat insulating layer, and the outer layer of the exhaust pipe is also covered with a heat insulating layer except the pipe wound on the porous media burner. The heat insulation layer is one of asbestos heat insulation layer, vacuum heat insulation layer or airgel felt heat insulation layer, but not limited to asbestos heat insulation layer, vacuum heat i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com