Composite double-layer photo-anode film, preparation method thereof and dye-sensitized solar cell

A composite double-layer and photoanode technology, applied in the field of dye-sensitized solar cells, can solve the problems of unsatisfactory improvement of solar photoelectric efficiency, low photoelectric efficiency of photoanode films, etc., and achieves strong dye adsorption capacity and large light absorption. The effect of range, large light-capturing capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

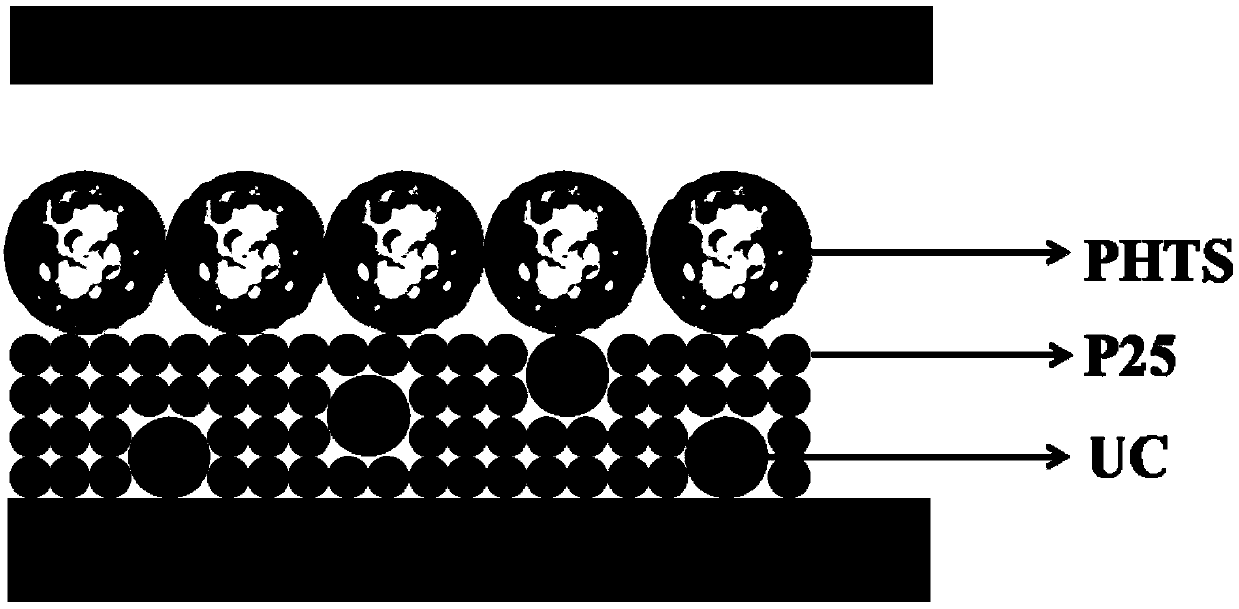

[0041] The present invention also provides a method for preparing the above-mentioned composite double-layer photoanode film, which comprises the following steps:

[0042] NaYbF 4 : Ho 3+ The up-conversion luminescent powder is mixed with titanium dioxide powder, and the first dispersant, the first leveling agent, and the first pore-forming film-forming agent are added to prepare the first viscous slurry; the first viscous slurry is coated on the surface of the conductive glass and dried, Annealing treatment to form a composite luminescent layer on the surface of conductive glass;

[0043] Mix the porous hollow titanium dioxide microspheres with the second dispersant, the second leveling agent, and the second pore-forming film-forming agent to prepare a second viscous slurry, apply the second viscous slurry on the surface of the composite luminescent layer and dry , Annealing treatment.

[0044] Wherein, preferably, the first dispersant and the second dispersant are selecte...

Embodiment 1

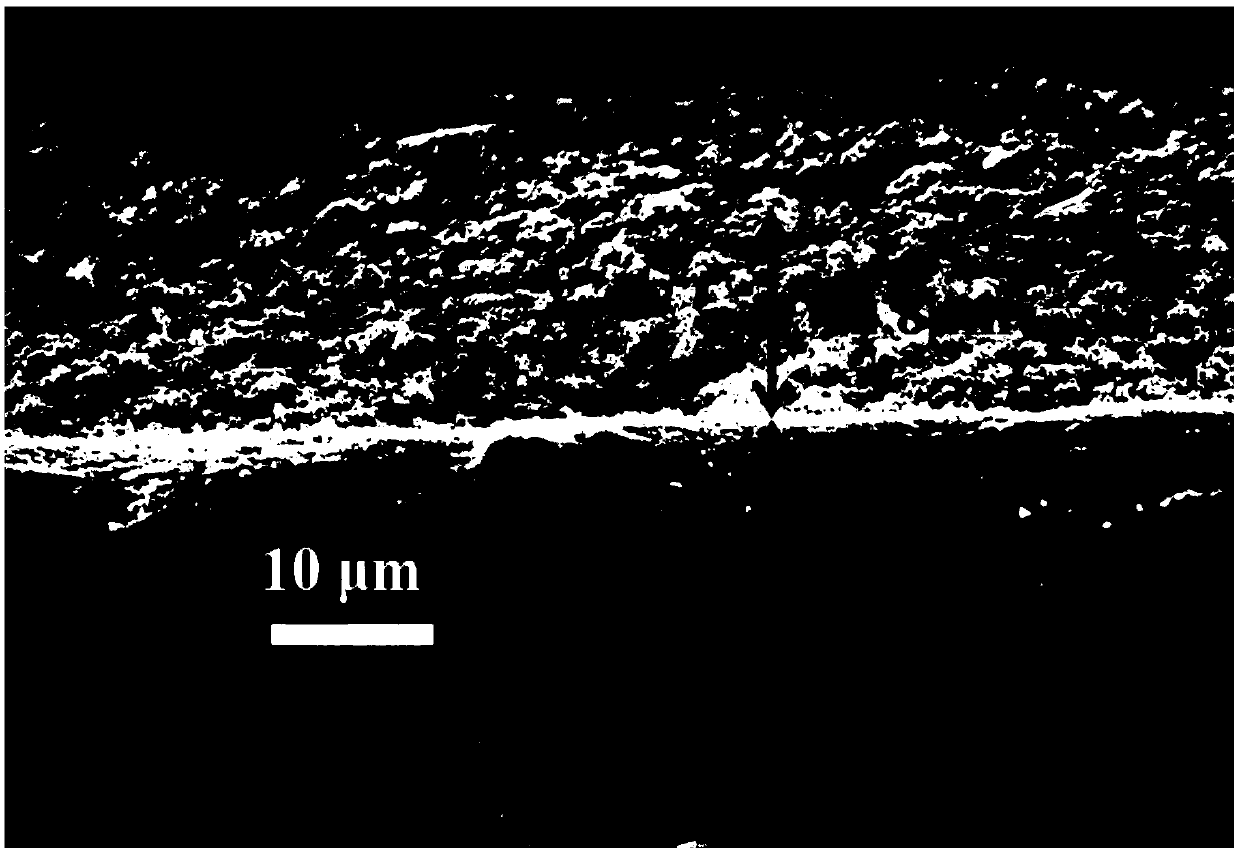

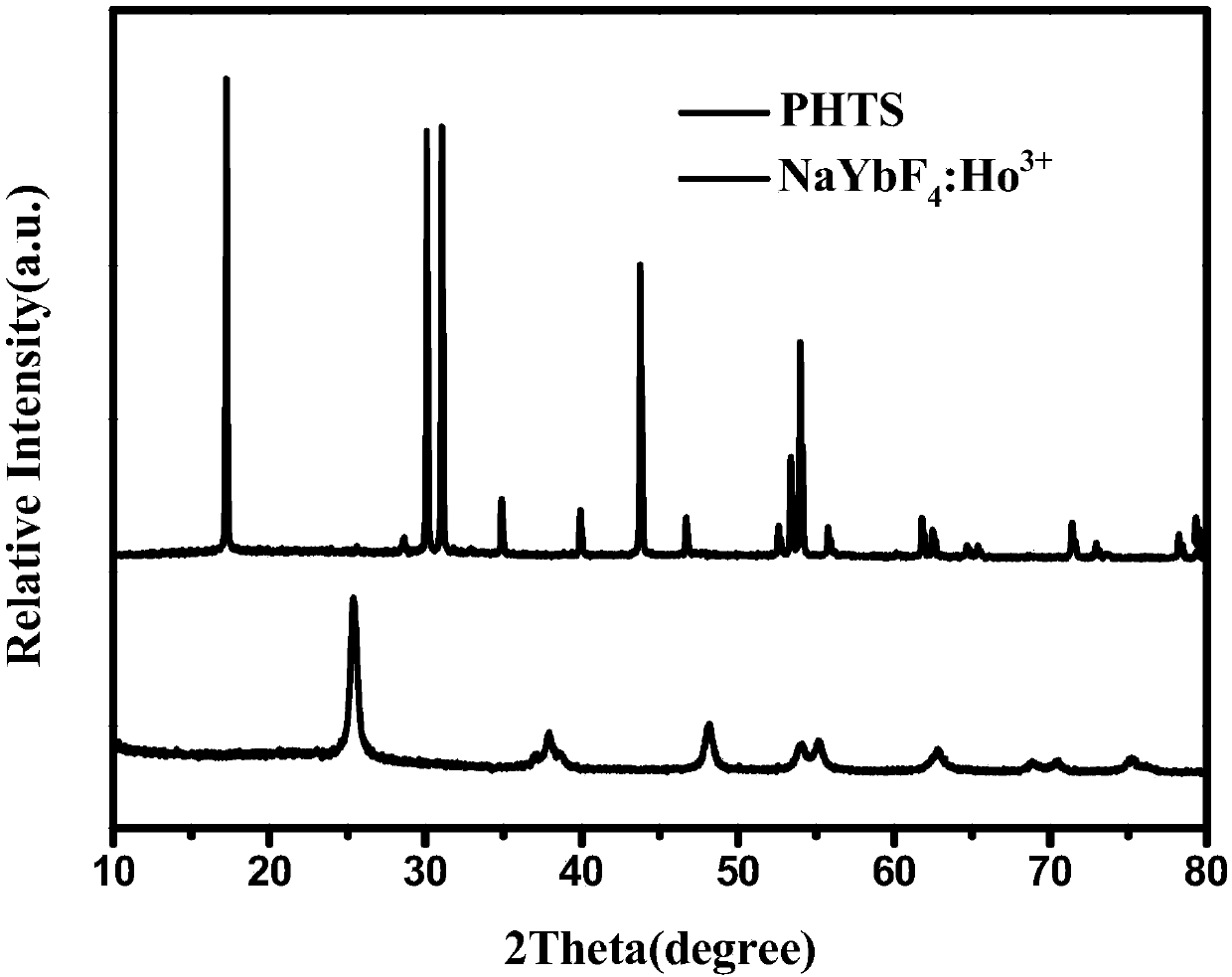

[0058] The embodiment of the present invention provides a composite double-layer photoanode film, which is prepared by the following steps:

[0059] S11. The above-prepared NaYbF 4 : Ho 3+Mix up-conversion luminescent powder and P25 titanium dioxide powder at a mass ratio of 3:97 to obtain a mixture; weigh 1.5 g of the obtained mixture and put it into a 100ml small beaker, and mix it with 50mL of absolute ethanol, isopropanol, acetone, glacial acetic acid, One or more dispersants in acetylacetone, 5.0g turpentine permeating alcohol leveling agent, 8.25g of ethyl cellulose, methyl cellulose, carboxy cellulose, hydroxymethyl cellulose, hydroxypropyl cellulose A pore-forming film-forming agent is fully mixed, then stirred and heated to prepare the first viscous slurry, and the first viscous slurry is coated on the surface of the FTO conductive glass, and the coating thickness is controlled to the thickness of two layers of adhesive tape with 3M adhesive tape. Then, after drying...

Embodiment 2

[0063] The embodiment of the present invention provides a composite double-layer photoanode film, which is prepared by the following steps:

[0064] S21. The above-prepared NaYbF 4 : Ho 3+ The up-conversion luminescent powder and P25 powder were mixed according to the mass ratio of 1:99, 2:98, 4:96, 5:95, and 6:94 to obtain the mixture, and 1.5g of the obtained mixture was weighed and put into 5 In a 100ml small beaker, numbered 1, 2, 3, 4, 5, and respectively mixed with 50mL of absolute ethanol, isopropanol, acetone, glacial acetic acid, acetylacetone or one or more dispersants, 5.0g turpentine Permeable alcohol leveling agent, 8.25g of a pore-forming film-forming agent in ethyl cellulose, methyl cellulose, carboxy cellulose, hydroxymethyl cellulose, and hydroxypropyl cellulose is fully mixed, stirred and heated to make the dispersant After volatilization to a certain extent, 5 groups of the first viscous slurry were prepared;

[0065] S22. Coat the 5 groups of the first v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com