Magnetic porous adsorbent and preparation method thereof

A porous adsorbent and magnetic technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of high cost of adsorbent, complicated preparation process, inconvenient separation, etc., and achieve simple process, Wide environmental applicability and simplified time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

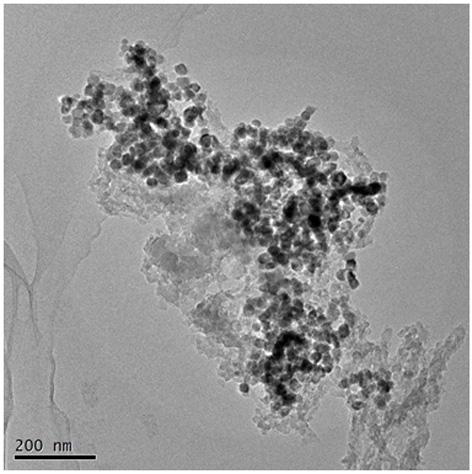

Image

Examples

Embodiment 1

[0023] (1) Disperse 1.0 g of melamine resin, 5.0 g of cetyltrimethylammonium bromide, and 1.0 g of ferric oxide in deionized water, add 0.1 mL of formic acid, mix well, and react at 40°C for 10 min to prepare Obtain a mixed solution containing magnetic complexes;

[0024] (2) Add 60.0 mL of 1 wt% hydrochloric acid solution containing 0.5 g chitosan to the mixed solution containing the magnetic complex obtained in step (1), and mix well;

[0025] (3) Add 2.0 mL of ammonia water and 2.0 mL of formaldehyde to the mixture obtained in step (2), and stop the reaction after cross-linking reaction at 40°C for 0.5 h to form a cross-linked porous composite;

[0026] (4) Adjust the pH of the solution obtained in step (3) to neutral, separate the product with a magnetic field, wash it repeatedly with deionized water and dry it, and then reflux with absolute ethanol to remove excess cetyl trimethyl bromide ammonium to obtain a magnetic porous adsorbent.

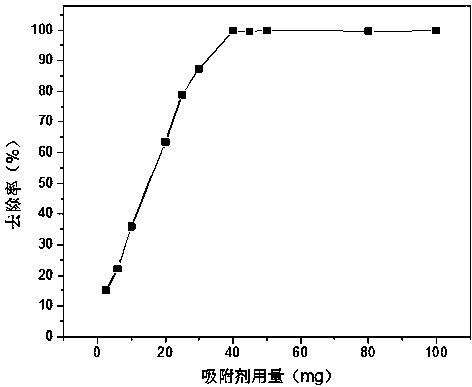

[0027] 40 mg of adsorbent was ad...

Embodiment 2

[0029] (1) Disperse 3.0 g of melamine resin, 25.0 g of hexadecyltrimethylammonium bromide and 2.5 g of ferric oxide in deionized water, add 0.8 mL of formic acid, mix well, and react at 60°C for 40 min to prepare Obtain a mixed solution containing magnetic complexes;

[0030] (2) Add 60.0 mL of 1 wt% hydrochloric acid solution containing 3.0 g chitosan to the mixed solution containing the magnetic complex obtained in step (1), and mix well;

[0031] (3) Add 10.0 mL of ammonia water and 1.0 mL of epichlorohydrin to the mixture obtained in step (2), and stop the reaction after cross-linking reaction at 60°C for 1.0 h to form a cross-linked porous composite;

[0032] (4) Adjust the pH of the solution obtained in step (3) to neutral, separate the product with a magnetic field, wash it repeatedly with deionized water and dry it, and then reflux with absolute ethanol to remove excess cetyl trimethyl bromide ammonium to obtain a magnetic porous adsorbent.

[0033] 40 mg of adsorben...

Embodiment 3

[0035] (1) Disperse 1.0 g of melamine resin, 40.0 g of cetyltrimethylammonium bromide and 4.0 g of ferric oxide in deionized water, add 1.5 mL of formic acid, mix well, and react at 70°C for 90 min to prepare Obtain a mixed solution containing magnetic complexes;

[0036] (2) Add 60.0 mL of 1 wt% hydrochloric acid solution containing 5.0 g of chitosan to the mixed solution containing the magnetic complex obtained in step (1), and mix well;

[0037] (3) Add 25.0 mL of ammonia water, 3.0 mL of formaldehyde and 5.0 mL of epichlorohydrin to the mixture obtained in step (2), stop the reaction after 3.0 hours of cross-linking reaction at 80°C, and generate a cross-linked porous composite;

[0038] (4) Adjust the pH of the solution obtained in step (3) to neutral, separate the product with a magnetic field, wash it repeatedly with deionized water and dry it, and then reflux with absolute ethanol to remove excess cetyl trimethyl bromide ammonium to obtain a magnetic porous adsorbent....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com