Zinc-aluminum hydrotalcite with book-page morphology, and preparation method and application thereof

A zinc-aluminum hydrotalcite, zinc-aluminum hydrotalcite technology, applied in chemical instruments and methods, water pollutants, zinc compounds, etc., can solve the problems of unreported and few zinc-aluminum hydrotalcite preparation, and achieve low cost , the effect of short time-consuming, cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

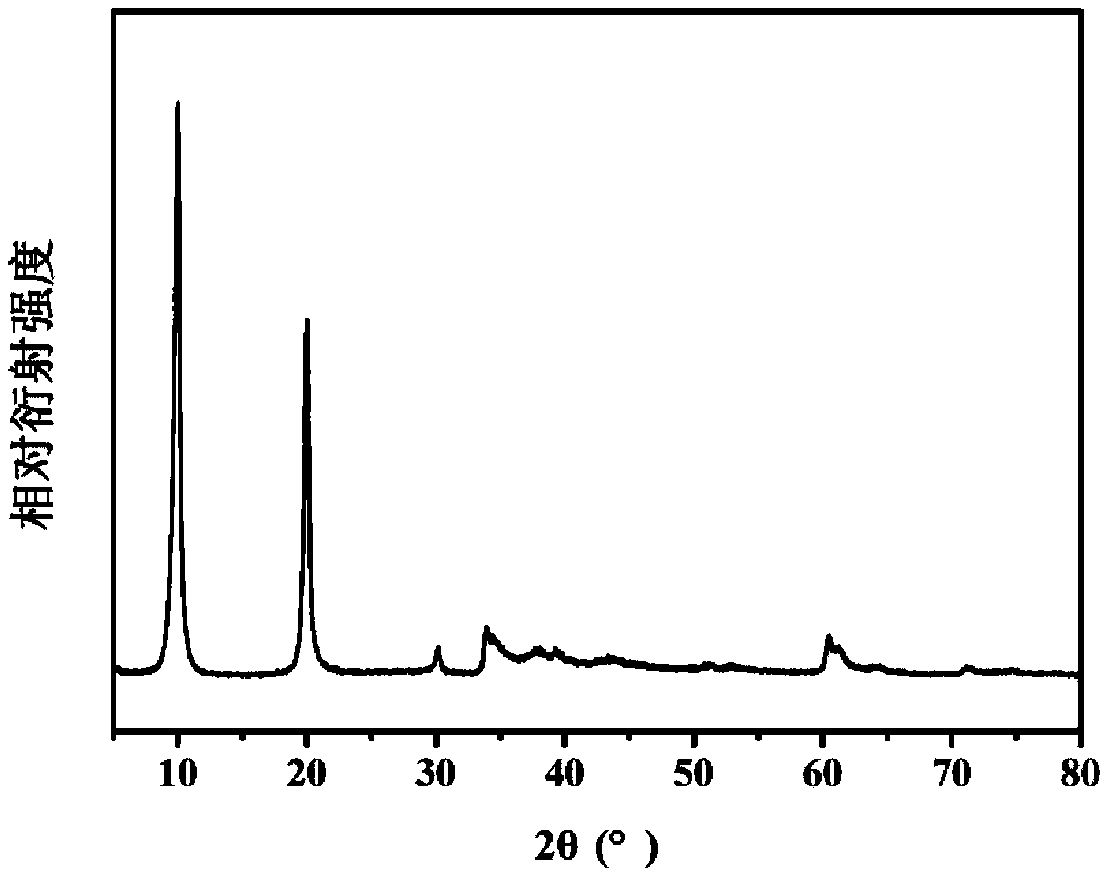

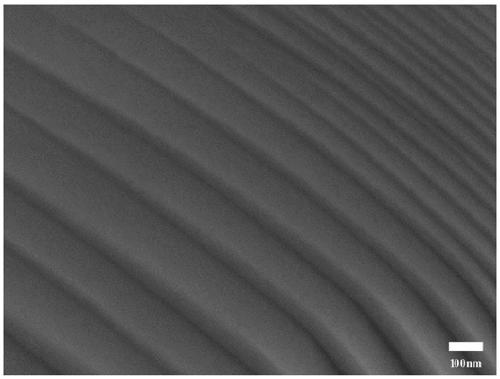

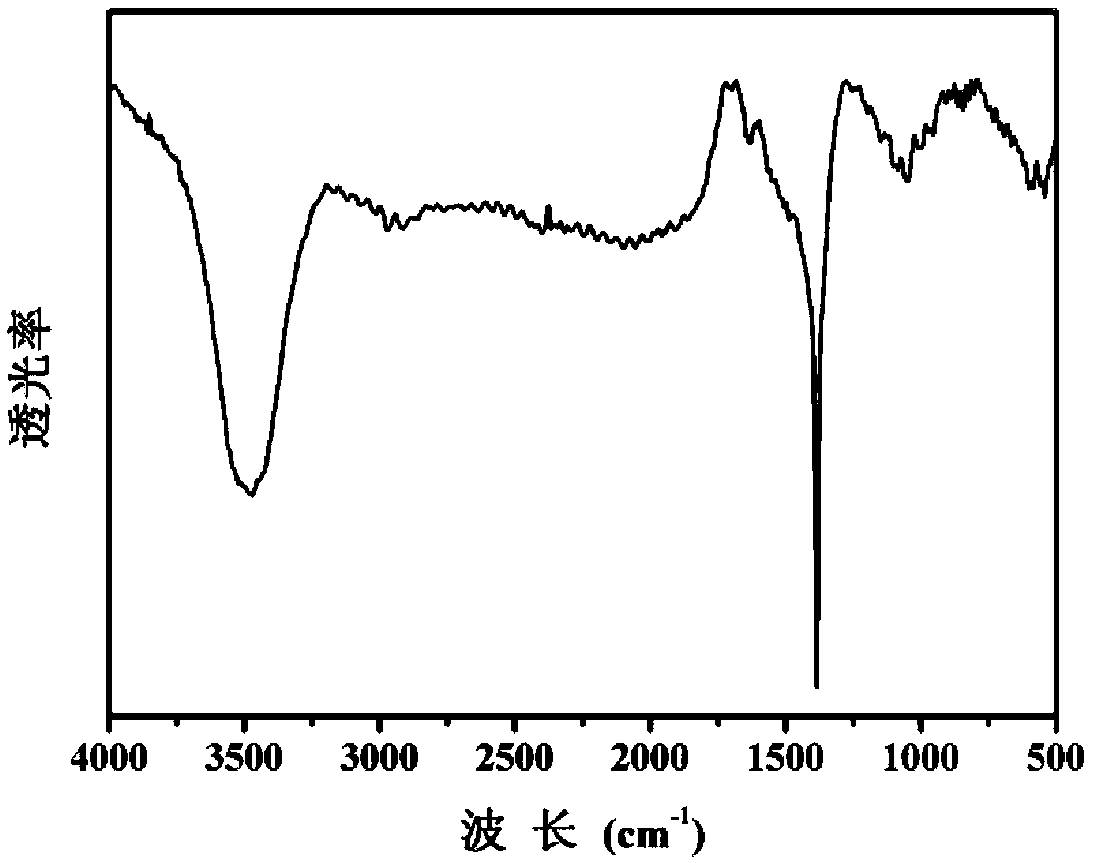

[0027] Weigh 4.0161g Zn(NO 3 ) 2 ·6H 2 O and 1.6883g Al(NO 3 ) 3 9H 2 Add O into a beaker containing 30mL of deionized water, stir evenly at room temperature to form solution A; prepare a sodium hydroxide solution with a concentration of 1mol / L, and record it as solution B; slowly drop solution B into solution A and continue stirring , the pH is between 6 and 7 to obtain a suspension C; pour the suspension C into a reaction kettle and then put it into an oven at 100°C, the reaction time is 3 hours, the product is alternately washed with deionized water and ethanol and dried at room temperature to obtain the product Zn -Al LDHs, denoted as 3-Zn-Al LDHs.

Embodiment 2

[0029] Weigh 4.0161g Zn(NO 3 ) 2 ·6H 2 O and 1.6883g Al(NO 3 ) 3 9H 2 Add O into a beaker containing 30mL of deionized water, stir evenly at room temperature to form solution A; prepare a sodium hydroxide solution with a concentration of 1mol / L, and record it as solution B; slowly drop solution B into solution A and continue stirring , the pH is 6-7, and the suspension C is obtained; the suspension C is poured into the reaction kettle and then placed in a 100°C oven, the reaction time is 6 hours, the product is alternately washed with deionized water and ethanol and dried at room temperature to obtain the product Zn -Al LDHs, denoted as 6-Zn-Al LDHs.

Embodiment 3

[0031] Weigh 4.0161g Zn(NO 3 ) 2 ·6H 2 O and 1.6883g Al(NO 3 ) 3 9H 2 Add O into a beaker containing 30mL of deionized water, stir evenly at room temperature to form solution A; prepare a sodium hydroxide solution with a concentration of 1mol / L, and record it as solution B; slowly drop solution B into solution A and continue stirring , the pH is 6-7, and the suspension C is obtained; the suspension C is poured into the reaction kettle and then placed in a 100°C oven, the reaction time is 9 hours, the product is alternately washed with deionized water and ethanol and dried at room temperature to obtain the product Zn -Al LDHs, denoted as 9-Zn-Al LDHs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com