A kind of preparation method of thermal barrier coating spray powder based on target coating phase structure and short flow plasma physical vapor deposition

A physical vapor deposition, target coating technology, applied in chemical instruments and methods, coatings, metal material coating processes, etc., can solve the problems of difficult to effectively control powder properties, difficult to sieve, and the strength cannot be too high. Achieve the effect of improving resource utilization efficiency, low cost, and improved deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) slurry preparation:

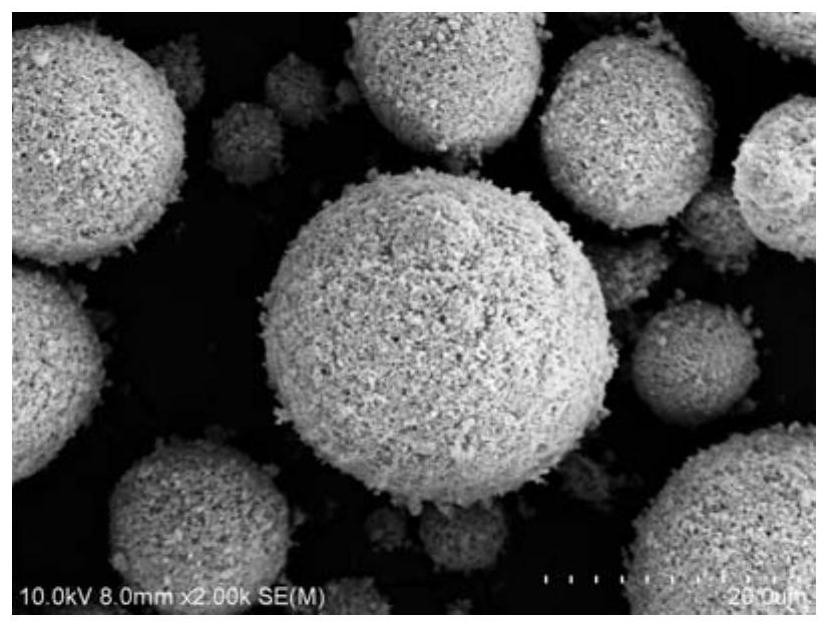

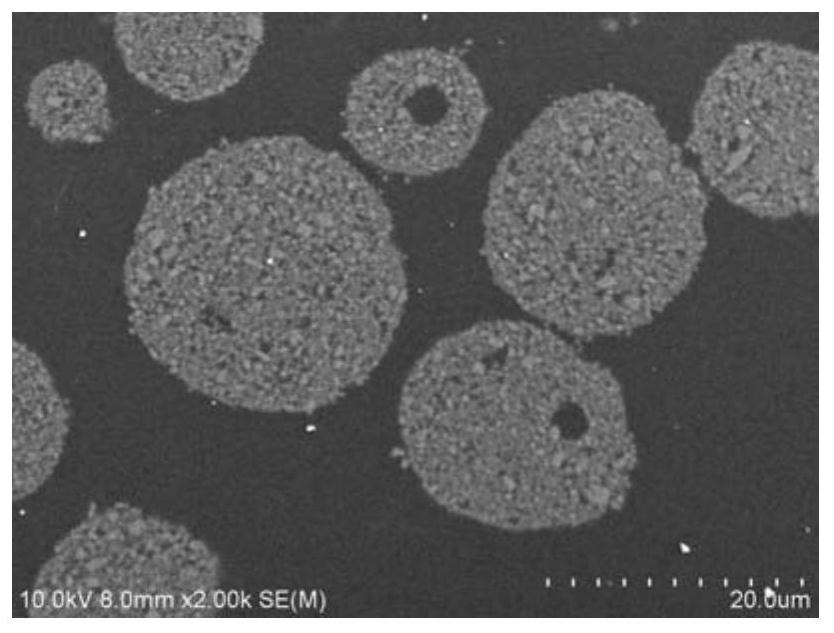

[0039] ① Weigh gadolinium zirconate (chemical formula: Gd 2 Zr 2 o 7 ) powder 2Kg, the D50 of the raw material is 50 μm, which is fine powder and coarse powder re-screened by plasma spraying powder, the powder is prepared through agglomeration and sintering, and the phase structure of the raw material powder is a pyrochlore structure;

[0040] ② The solid content of the configuration is 20%, divided into 1Kg powder and ball milled, respectively adding 1% phenolic resin to the respective slurry as a binder (the viscosity of the pure aqueous solution at this concentration is 1mPa·s),

[0041] ③Part of the slurry is ball milled at 300rpm using a stirring ball mill for 1h until D 50 0.15μm, D 75 0.28μm; the other part is milled at the relevant ball milling speed of 300rpm and ball milled for 15min. The particle size of the powder particles in the slurry is characterized by D50 being 3μm and D90 being 10μm;

[0042] ④Mix the above-mentioned slu...

Embodiment 2

[0053] (1) slurry preparation:

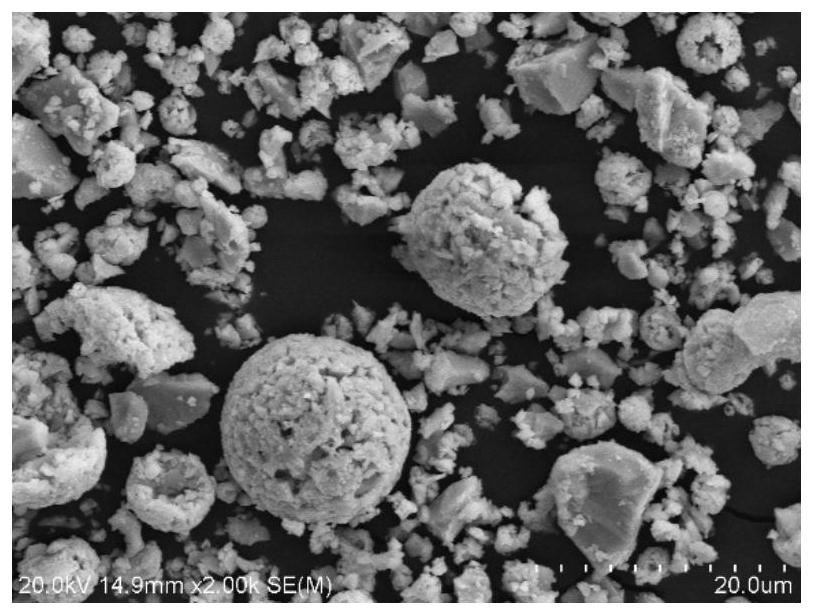

[0054] ①Weigh 8YSZ powder (6~8wt.%Y 2 o 3 Partially stabilized ZrO 2 Powder, the powder is a single metastable tetragonal phase structure (consistent with the target preparation coating phase structure), smelting and crushing powder) 5Kg, and the average particle size of the powder is 25 μm;

[0055] ② Divide the powder raw material into two parts of equal weight, add pure water to control the solid content to 60%, add 2% phenolic resin of the powder mass as a binder, the binder is dissolved in pure water at a concentration of 2%, and the viscosity of the solution is 2.1 mPa s;

[0056] ③ A part of ball milling to the powder particle size D in the slurry 50 0.1μm, D 75 0.23μm; the other part is ball milled to the powder particle D in the slurry 50 6μm, D 90 9.9 μm;

[0057] ④Mix the above-mentioned slurry with the same solid content and stir evenly. The viscosity of the slurry is 8mPa·s. After the slurry is uniformly stirred, the partic...

Embodiment 3

[0069] (1) slurry preparation:

[0070] ① Weigh lanthanum cerate (chemical formula: La 2 Ce 2 o 7 ) powder 4Kg, the D50 of the raw material is 42 μm, which is a nano-agglomerated sintered powder, and the phase structure of the raw material powder is; fluorite phase.

[0071] ② The solid content of the configuration is 40%, which is divided into 2Kg powder ball mills, and 1.5% phenolic resin is added to the respective slurries as a binder (the viscosity of the pure aqueous solution at this concentration is 1.6mPa·s),

[0072] ③Part of the slurry is ball milled at 250rpm with a stirring ball mill for 1.5h until D 50 0.14μm, D 75 0.25 μm; the other part is milled at a relevant ball mill speed of 250 rpm for 40 minutes, and the particle size of the powder in the slurry is characterized by D50 being 4.5 μm and D90 being 8.7 μm;

[0073] ④Mix the above-mentioned slurry with the same solid content and stir evenly. The viscosity of the evenly stirred slurry is 40mPa·s. After unif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| crushing strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com