Silica sol modified impact-resistant ceramic-imitating plastic and preparation method

A silica sol and impact-resistant technology is applied in the field of impact-resistant porcelain-like plastics modified by silica sol and its preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

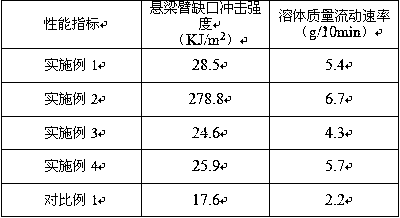

Examples

Embodiment 1

[0032] (1) Put the barium sulfate particles in a ball mill, and use grinding to make the barium sulfate raw material particles have micro-cracks to obtain barium sulfate with micro-cracks;

[0033] (2) Add the organic silicon source to absolute ethanol, heat up the water bath and stir, then add deionized water, and under the premise of continuous stirring in the water bath, use acid to adjust the pH of the system to acidic, and let it stand for reaction to obtain a silica sol precursor The organosilicon source is polysiloxane; the stirring temperature in the water bath is 46°C, the stirring speed is 360rpm, and the time is 68min; the acid is nitric acid; in the preparation of the silica sol precursor, absolute ethanol, organosilicon source, deionized water , the mass ratio of acid is 100:76:70:16;

[0034] (3) Atomize and deposit the silica sol precursor on the surface of barium sulfate with microcracks, and fully penetrate into the inside of the particles, then collect the pa...

Embodiment 2

[0040] (1) Put the barium sulfate particles in a ball mill, and use grinding to make the barium sulfate raw material particles have micro-cracks to obtain barium sulfate with micro-cracks;

[0041] (2) Add the organic silicon source to absolute ethanol, heat up the water bath and stir, then add deionized water, and under the premise of continuous stirring in the water bath, use acid to adjust the pH of the system to acidic, and let it stand for reaction to obtain a silica sol precursor The organosilicon source is polydimethylsiloxane; the temperature of the water bath stirring is 40°C, the stirring speed is 300rpm, and the time is 80min; the acid is sulfuric acid; in the preparation of the silica sol precursor, absolute ethanol, organosilicon source, The mass ratio of deionized water and acid is 100:50:40:10;

[0042] (3) Atomize and deposit the silica sol precursor on the surface of barium sulfate with microcracks, and fully penetrate into the inside of the particles, then co...

Embodiment 3

[0046] (1) Put the barium sulfate particles in a ball mill, and use grinding to make the barium sulfate raw material particles have micro-cracks to obtain barium sulfate with micro-cracks;

[0047] (2) Add the organic silicon source to absolute ethanol, heat up the water bath and stir, then add deionized water, and under the premise of continuous stirring in the water bath, use acid to adjust the pH of the system to acidic, and let it stand for reaction to obtain a silica sol precursor The organosilicon source is tetramethylsilane; the stirring temperature in the water bath is 50°C, the stirring speed is 400rpm, and the time is 60min; the acid is hydrochloric acid; in the preparation of the silica sol precursor, absolute ethanol, organosilicon source, deionized water , the mass ratio of acid is 100: 60: 80:20;

[0048] (3) Atomize and deposit the silica sol precursor on the surface of barium sulfate with microcracks, and fully penetrate into the inside of the particles, then c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com