Fully degradable simulation material and preparation method thereof

A fully degradable and simulated technology, applied in the field of simulated materials, can solve problems such as unfavorable industrial production, reduced mechanical properties, and cost provision, and achieve the effects of improving degradability, good mechanical properties, and avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

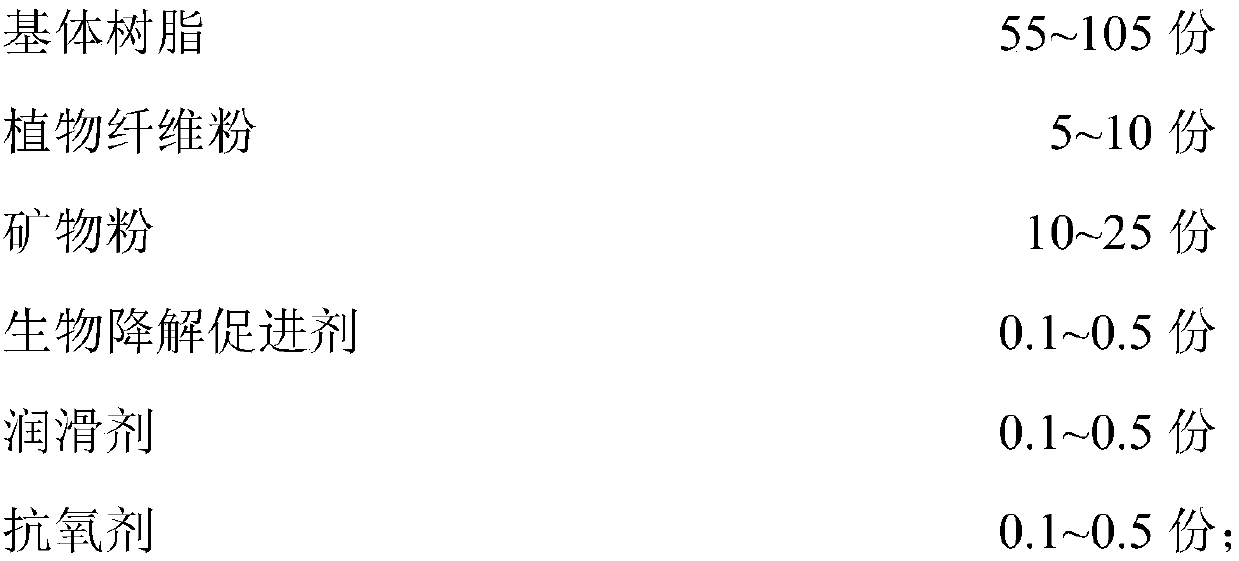

[0033] A fully degradable simulation material, comprising the following raw materials in parts by weight:

[0034]

[0035] The matrix resin is composed of 10 parts by weight of PLA, 60 parts by weight of PBAT and 5 parts by weight of PCL.

[0036] Wherein, the melting index of the PLA is 9g / min, the test condition is 210°C / 2.16kg, the weight average molecular weight is 50000, the glass transition temperature is 63°C, and the crystallization temperature is 158°C.

[0037] Wherein, the melting index of the PBAT is 4.5g / min, the test condition is 190°C / 2.16kg, the weight average molecular weight is 60,000, the Vicat softening point is 80°C, and the heat distortion temperature is 46°C.

[0038] Wherein, the melt index of the PCL is 5.6g / min, the test condition is 160°C / 2.16kg, the weight average molecular weight is 70000, and the melting temperature is 59°C.

[0039] Wherein, the plant fiber powder is bamboo powder, and the mesh number of the plant fiber powder is 700 mesh. ...

Embodiment 2

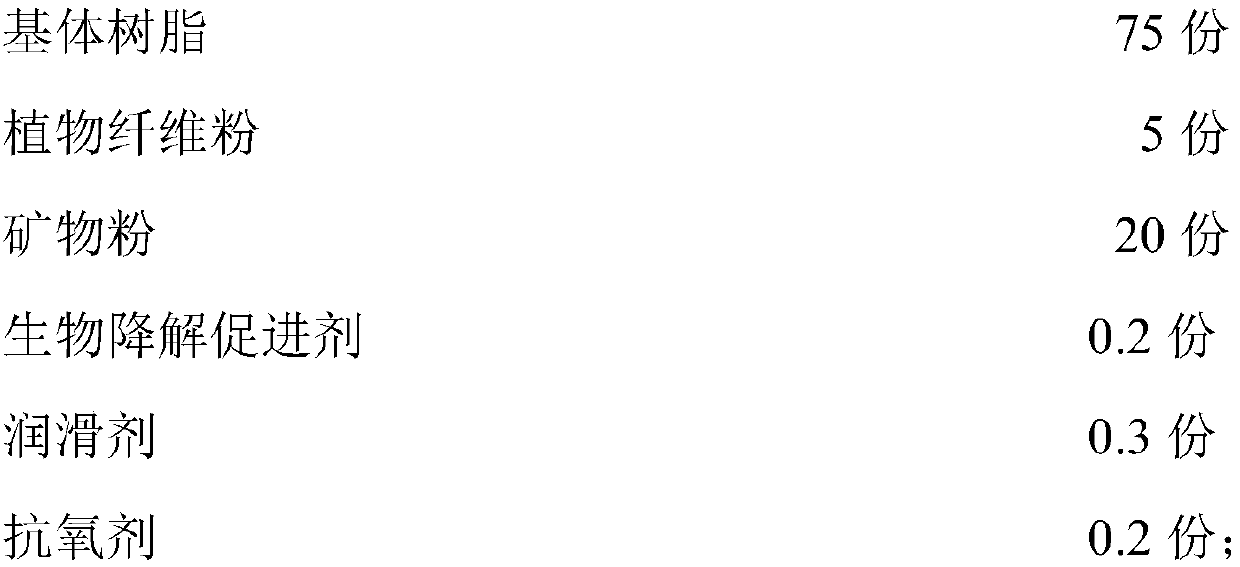

[0050] A fully degradable simulation material, comprising the following raw materials in parts by weight:

[0051]

[0052] The matrix resin is PBAT.

[0053] Wherein, the melting index of the PBAT is 4.5g / min, the test condition is 190°C / 2.16kg, the weight average molecular weight is 60,000, the Vicat softening point is 80°C, and the heat distortion temperature is 46°C.

[0054] Wherein, the plant fiber powder is wood powder, and the mesh number of the plant fiber powder is 700 mesh.

[0055] Wherein, the mineral powder is calcium carbonate, and the mesh number of the mineral powder is 5000 mesh.

[0056] Wherein, the biodegradation accelerator is N-fatty acyl glutamic acid.

[0057] Wherein, the lubricant is oleic acid amide.

[0058] Wherein, the antioxidant is tris(2,4-di-tert-butyl)phenyl phosphite.

[0059] A method for preparing a fully degradable simulation material as described above, comprising the following steps;

[0060] (1) Take the matrix resin and stir ...

Embodiment 3

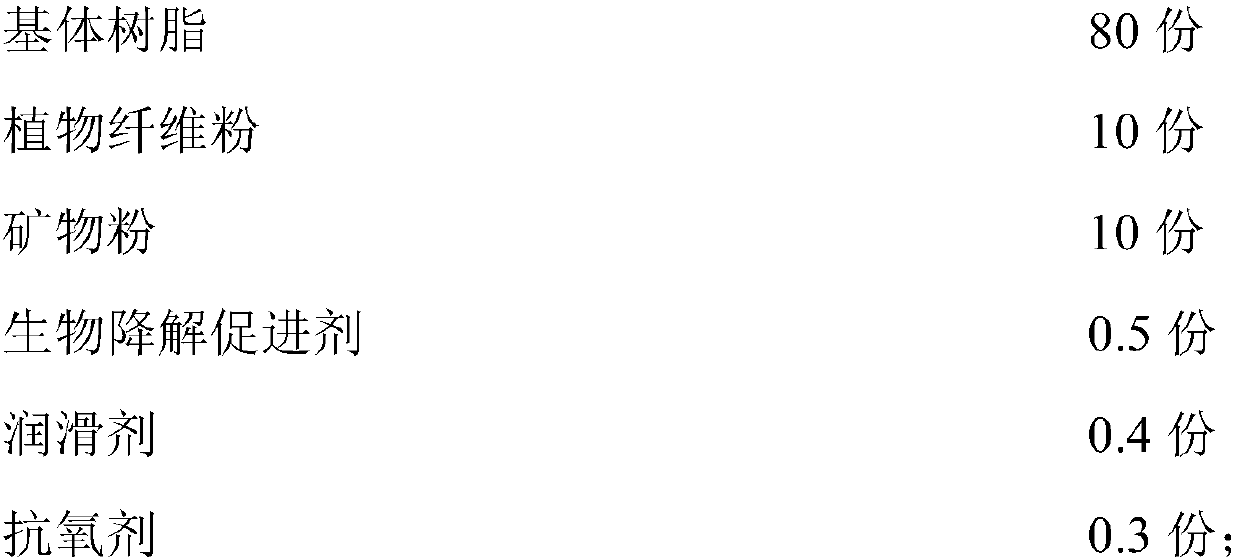

[0065] A fully degradable simulation material, comprising the following raw materials in parts by weight:

[0066]

[0067] The matrix resin is composed of 15 parts by weight of PLA, 55 parts by weight of PBAT and 10 parts by weight of PCL.

[0068] Wherein, the melting index of the PLA is 9g / min, the test condition is 210°C / 2.16kg, the weight average molecular weight is 50000, the glass transition temperature is 63°C, and the crystallization temperature is 158°C.

[0069] Wherein, the melting index of the PBAT is 4.5g / min, the test condition is 190°C / 2.16kg, the weight average molecular weight is 60,000, the Vicat softening point is 80°C, and the heat distortion temperature is 46°C.

[0070] Wherein, the melt index of the PCL is 5.6g / min, the test condition is 160°C / 2.16kg, the weight average molecular weight is 70000, and the melting temperature is 59°C.

[0071] Wherein, the plant fiber powder is tea powder, and the mesh number of the plant fiber powder is 700 mesh.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com