Water-based magnetic auxiliary polishing liquid, preparation method thereof and magnetorheological polishing liquid

A polishing liquid, water-based technology, applied in polishing compositions containing abrasives, etc., can solve the problem of not meeting the rust prevention of magnetic media or the suspension stability of polishing liquid, and cannot meet the requirements of magnetic-assisted polishing technology for liquid performance, Unable to meet the problems of rust prevention and stability of removal efficiency, and achieve the effect of good magnetic medium rust protection ability, stable material removal efficiency and good anti-settling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

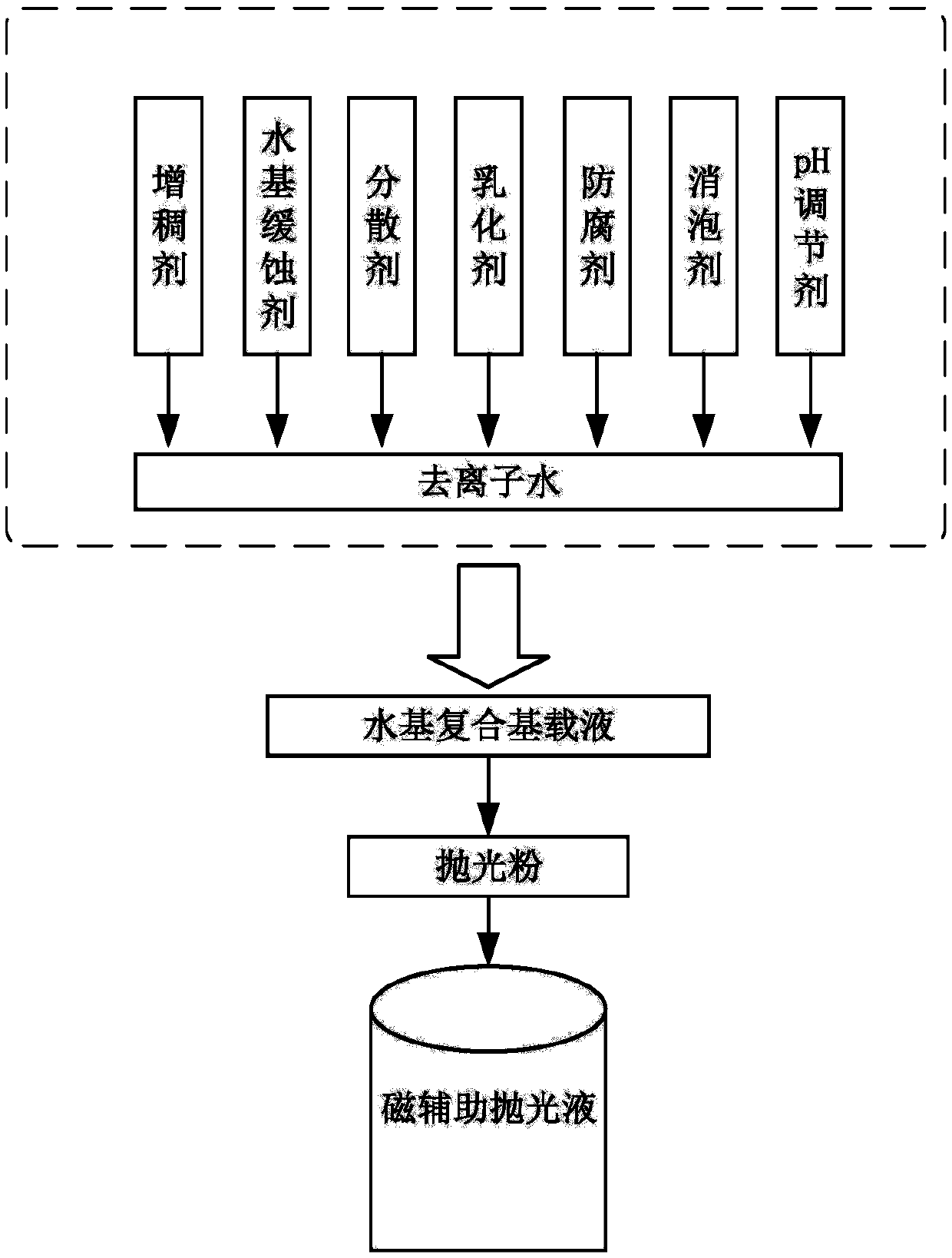

[0035] The specific embodiment of the present invention also provides a kind of preparation method of above-mentioned water-based magnetic assisted polishing liquid, and described preparation method comprises steps:

[0036] Step 1: adding the thickener into deionized water in parts by mass, and stirring for the first time at the first temperature to obtain the first solution;

[0037] Step 2: adding the water-based corrosion inhibitor to the first solution in parts by mass, and stirring for the second time at the second temperature to obtain the second solution;

[0038] Step 3: adding the dispersant to the second solution in parts by mass, and stirring for the third time at a third temperature to obtain a third solution;

[0039] Step 4: adding the emulsifier to the third solution in parts by mass, and stirring for the fourth time at a fourth temperature to obtain the fourth solution;

[0040] Step 5: adding the antiseptic to the fourth solution in parts by mass, and stirri...

Embodiment 1

[0060] Prepare a water-based magnetic-assisted polishing solution, the polishing powder is: cerium oxide, the particle size is 3 μm, and the mass is 200 g. The composition of the water-based composite carrier liquid is: deionized water 3000ml, thickener sodium carboxymethylcellulose 20g, water-based corrosion inhibitor sodium tripolyphosphate 15g, dispersant polysodium methacrylate 50g, emulsifier tween 80, mass 80g, preservative sodium benzoate 1g, antifoaming agent silicon polyether 0.5g, pH regulator sodium carbonate 15g.

[0061] The specific preparation steps are as follows:

[0062] Step 1. Add 20g of sodium carboxymethylcellulose into 3000ml of deionized water and stir for 3 hours. The speed of the disperser is set to 1000r / min, and the temperature is controlled at 60°C.

[0063] Step 2. Add 15g of water-based corrosion inhibitor sodium tripolyphosphate to the solution obtained in step 1, and stir with a stirrer for 2 hours. The speed of the stirrer is set to 400r / min,...

Embodiment 2

[0071] A water-based magnetic-assisted polishing solution was prepared, and the polishing powder was: diamond micropowder with a particle size of 0.5 μm and a mass of 100 g. The composition of the water-based composite carrier liquid is: 2000ml of deionized water, 10g of sodium polyacrylate, 10g of water-based corrosion inhibitor ammonium citrate, 40g of dispersant sodium dodecylbenzenesulfonate, 80g of emulsifier polyethylene glycol, preservative Sodium benzoate 0.8g, antifoaming agent silicon polyether 0.5g, pH regulator sodium hydroxide 10g.

[0072] The specific preparation steps are as follows:

[0073] Step 1. Add 10g of sodium polyacrylate into 2000ml of deionized water and stir for 3 hours. The speed of the disperser is set to 1000r / min, and the temperature is controlled at 60°C.

[0074] Step 2. Add 10g of water-based corrosion inhibitor ammonium citrate to the solution obtained in step 1, and stir for 2 hours with a stirrer, the speed of the stirrer is set at 400r / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com