Novel hydrophilic anti-pollution polyvinylidene fluoride flat membrane, and preparation method and application thereof

A technology of polyvinylidene fluoride film and polyvinylidene fluoride, applied in the field of preparation of new hydrophilic anti-pollution polyvinylidene fluoride flat film, can solve the problem of poor antibacterial effect, poor mechanical strength, and unstable MBR reactor To achieve excellent antibacterial effect, improve antibacterial performance, and delay membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The GO / TiO of this embodiment 2 / PVDF flat membrane preparation method, its steps are as follows:

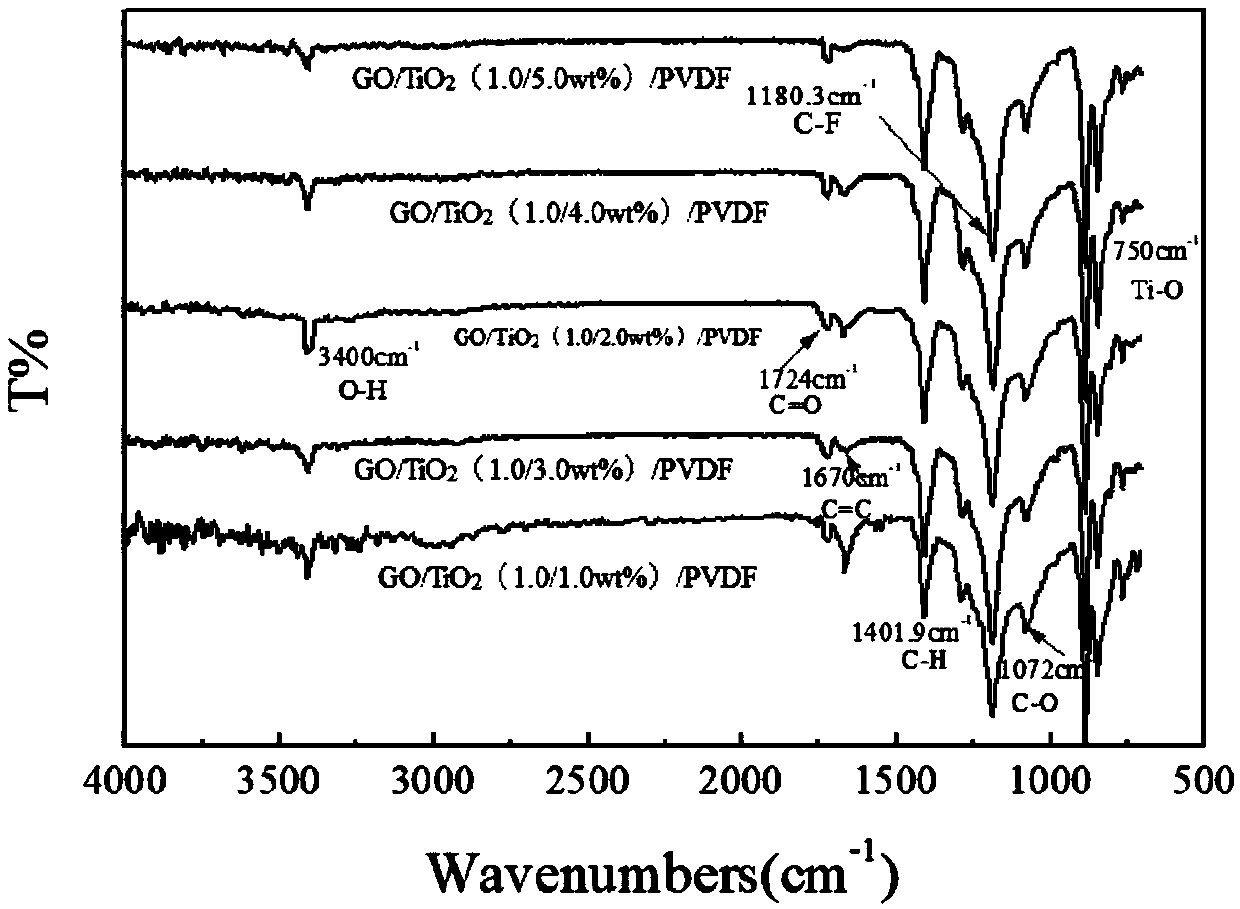

[0052] (1) Preparation of graphene oxide (GO): GO is prepared using the Improved Hummers method. The specific steps are as follows: prepare a mixed acid solution (90% concentrated sulfuric acid and 10% concentrated phosphoric acid), and measure 46.0mL of the mixed acid solution into a three-necked flask medium (500 mL), put the three-necked flask in an ice-water bath, add 2.0 g flake graphite powder, 1.0 g sodium nitrate, stir for 30 min, then stir in a 35°C water bath for 60 min. Then the temperature of the water bath was raised to 60°C, and 98.0 mL of deionized water was continuously added dropwise with a separatory funnel, and then the temperature was adjusted to 98°C, and the stirring reaction was continued for 30 minutes. The reaction mixture was diluted and rinsed with deionized water, then 15mL of 5% hydrogen peroxide and 20mL of 5% HCl were added dropwise until t...

Embodiment 2

[0056] In this embodiment PVDF / GO / TiO 2 Flat membrane preparation method, its implementation steps are basically the same as in Example 1, the difference is: the GO and nano-scale TiO 2 The mass ratio of the casting solution is 1:2; the mass ratio of the components of the casting solution is PVDF: DMAC: GO: TiO 2 =10:80:1:1; the scraping film speed in the step (2) is 3 cm / s; the scraping film thickness is 200 μm. The flat film obtained in this example is GO / TiO 2 (1.0 / 2.0 wt%) / PVDF.

Embodiment 3

[0058] In this embodiment PVDF / GO / TiO 2 Flat membrane preparation method, its implementation steps are basically the same as in Example 1, the difference is: the GO and nano-scale TiO 2 The mass ratio of the casting solution is 1:3; the mass ratio of each component of the casting solution is PVDF:DMAC:GO:TiO 2 =15:84:1:3; the scraping film speed in the step (2) is 6 cm / s; the scraping film thickness is 250 μm. The flat film obtained in this example is GO / TiO 2 (1.0 / 3.0 wt%) / PVDF.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com