Tracking-resistant ethylene propylene diene monomer sealing material and preparation method thereof

An EPDM rubber, anti-tracking technology, applied in mechanical equipment, engine components, piston rings, etc., can solve problems affecting the safe operation of converter valves, seal ring ablation, seal failure, etc., to improve durability The effect of tracking performance and mechanical properties, reducing ablation and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

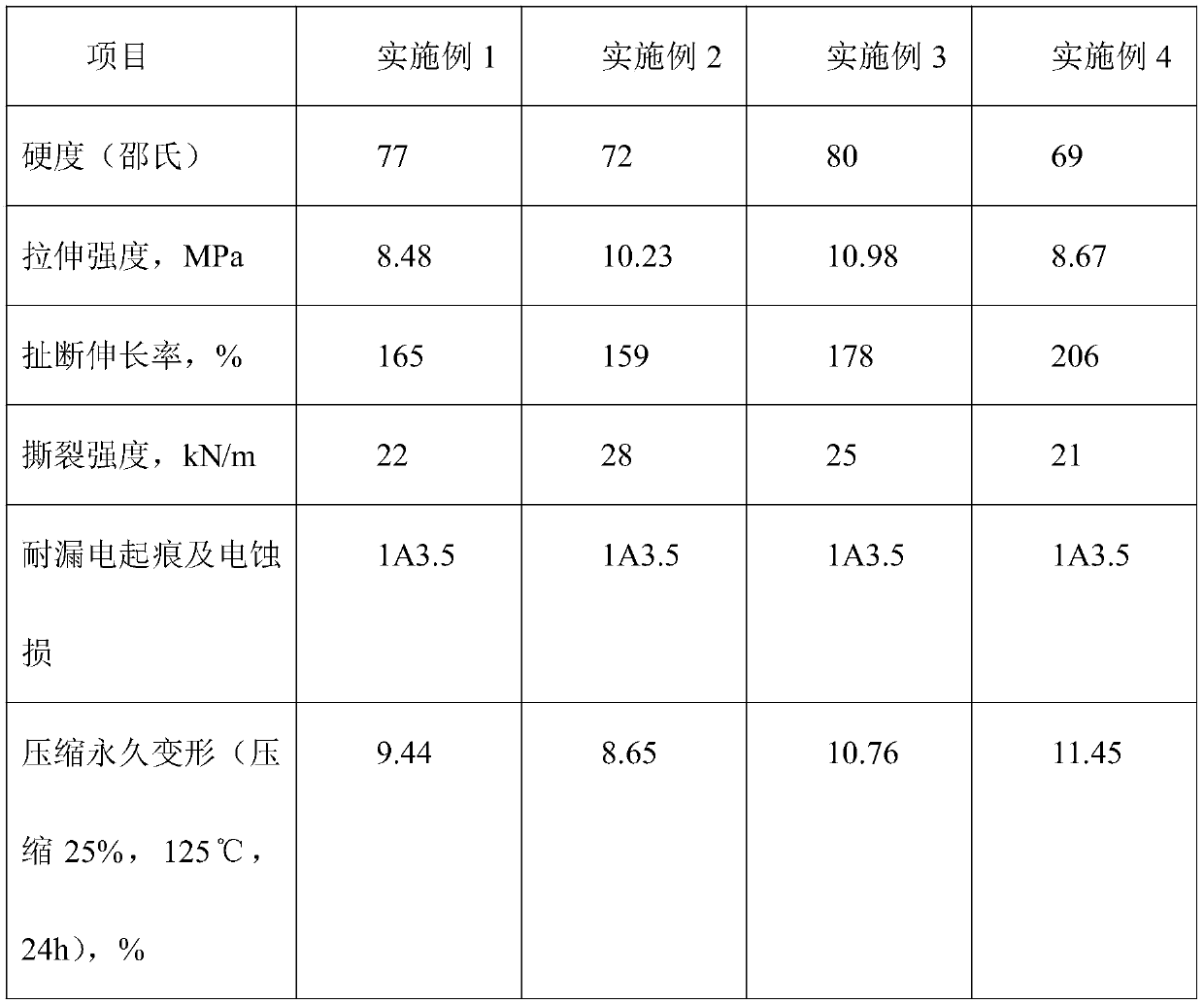

Examples

Embodiment 1

[0028] A tracking-resistant EPDM sealing material, the raw materials of which include by weight: 100 parts of EPDM rubber, 60 parts of carbon black, 60 parts of activated aluminum hydroxide, 20 parts of nano-alumina, multi-walled carbon 10 parts of nanotubes, 20 parts of paraffin oil, 5 parts of zinc oxide, 4 parts of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, 1 part of tripropenyl isocyanurate share. Among them, the Mooney viscosity of EPDM rubber (ML1+4, 125°C) is 25, the content of ethylene monomer is 53%, the content of the third monomer ethylidene norbornene is 6%; the carbon black is fast extrusion furnace black , the particle size is 40nm; the activated aluminum hydroxide is activated aluminum hydroxide surface modified by the silane coupling agent KH550, the mesh number is 2000 mesh, and the purity is above 99.6%; the diameter of the multi-walled carbon nanotube is 10nm, and the tube length is 30μm. The purity is more than 98%; the crystal form of nano-alumina is α...

Embodiment 2

[0036] A tracking-resistant EPDM sealing material, the raw materials of which include by weight: 100 parts of EPDM rubber, 40 parts of carbon black, 70 parts of activated aluminum hydroxide, 20 parts of nano-alumina, multi-walled carbon 30 parts of nanotubes, 10 parts of paraffin oil, 3 parts of zinc oxide, 3.5 parts of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, 1.5 parts of tripropenyl isocyanurate share. Among them, the Mooney viscosity of EPDM rubber (ML1+4, 125°C) is 28, the content of ethylene monomer is 48%, the content of the third monomer ethylidene norbornene is 7.8%; the carbon black is fast extrusion furnace black , with a particle size of 40nm; activated aluminum hydroxide is surface-modified activated aluminum hydroxide with a titanate coupling agent (tetrabutyl orthotitanate), with a mesh number of 5000 mesh and a purity of over 99.6%; multi-walled carbon nano The tube has a diameter of 10nm, a tube length of 20μm, and a purity of more than 98%; the crystal f...

Embodiment 3

[0044]A tracking-resistant EPDM sealing material, the raw materials of which include by weight: 100 parts of EPDM rubber, 60 parts of carbon black, 70 parts of activated aluminum hydroxide, 15 parts of nano-alumina, multi-walled carbon 20 parts of nanotubes, 15 parts of paraffin oil, 4 parts of zinc oxide, 3 parts of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, 1.5 parts of tripropenyl isocyanurate share. Among them, the Mooney viscosity of EPDM rubber (ML1+4, 125°C) is 25, the content of ethylene monomer is 53%, the content of the third monomer ethylidene norbornene is 6%; the carbon black is fast extrusion furnace black , the particle size is 40nm; the activated aluminum hydroxide is activated aluminum hydroxide surface modified by the silane coupling agent KH550, the mesh number is 5000 mesh, and the purity is above 99.6%; the multi-walled carbon nanotubes have a diameter of 10nm and a length of 20μm , with a purity of over 98%; the crystal form of nano-alumina is α phase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com