Novel antibiotic bone cement and preparation method thereof

A technology of antibiotics and bone cement, applied in tissue regeneration, pharmaceutical formulations, prostheses, etc., can solve the problems of poor antibiotic interaction, limited application, and unstudied thermal stability, etc., to achieve expanded antibacterial spectrum, good antibacterial properties, and improved The effect of the antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

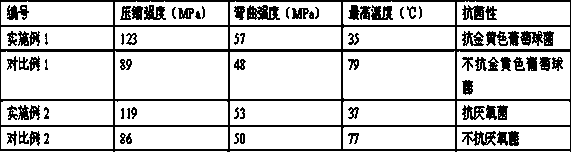

Examples

Embodiment 1

[0041] This embodiment relates to a novel antibiotic bone cement and its preparation method, the preparation method comprising the following steps:

[0042] Step 1, component A preparation:

[0043] (1) Matrix material preparation: Bisphenol A diglycidyl methacrylate (Bis-GMA) and triethylene glycol dimethacrylate (TEGDMA) were mixed with an electric stirrer for more than 12 h to make them evenly mixed. Bis-GMA accounts for 30 parts of the total mass of ingredients, and TEGDMA accounts for 28 parts of the total mass of ingredients.

[0044] (2) After preparing according to the base material, add benzoyl peroxide to the base material and continue mixing for more than 12 h. The initiator accounts for 0.5 part of the overall mass of the batching.

[0045] (3) After mixing (2), add 17.5 parts of zirconium dioxide, 20 parts of bioglass, and 4 parts of amoxicillin sodium, and make a paste by electric mixing. A production.

[0046] Step 2, component B preparation:

[0047] (1) M...

Embodiment 2

[0055] This embodiment relates to a novel antibiotic bone cement and its preparation method, the preparation method comprising the following steps:

[0056] Step 1, component A preparation:

[0057] (1) Matrix material preparation: Mix bisphenol A ethoxy dimethacrylate (Bis-GMA) and triethylene glycol dimethacrylate (TEGDMA) with an electric mixer for more than 12 hours to make them evenly mixed . Bis-GMA accounts for 20 parts of the total mass of ingredients, and TEGDMA accounts for 40 parts of the total mass of ingredients.

[0058] (2) After preparing according to the matrix material, add benzoyl tert-butyl peroxide to the matrix material and continue mixing for more than 12 hours. The initiator accounts for 0.3 parts of the overall mass of the batching.

[0059] (3) After mixing (2), add 23 parts of barium sulfate, 9.7 parts of bioglass, 5 parts of ciprofloxacin hydrochloride, and 2 parts of gentamicin sulfate, and mix and stir to form Paste substance, the preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com