Robot production line for producing organic fertilizer

A robot and production line technology, applied in mixers, mixers, dryers and other directions with rotary stirring devices, can solve the problem of imperfect crushing and conveying process of organic fertilizer raw materials, poor processing effect of organic fertilizer raw materials, and insufficient process layout Clear and other problems to achieve the effect of increasing space utilization, good crushing effect and good production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

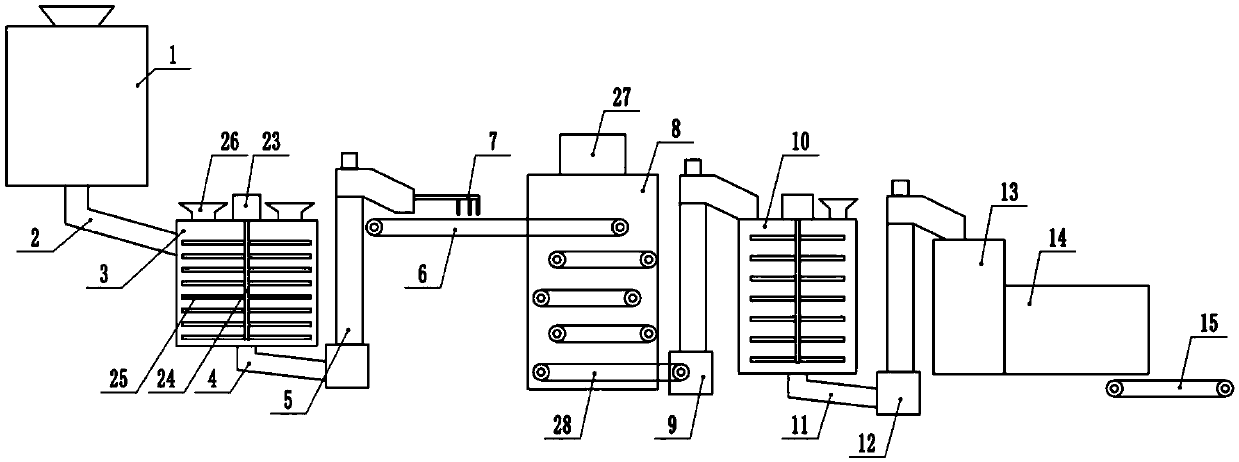

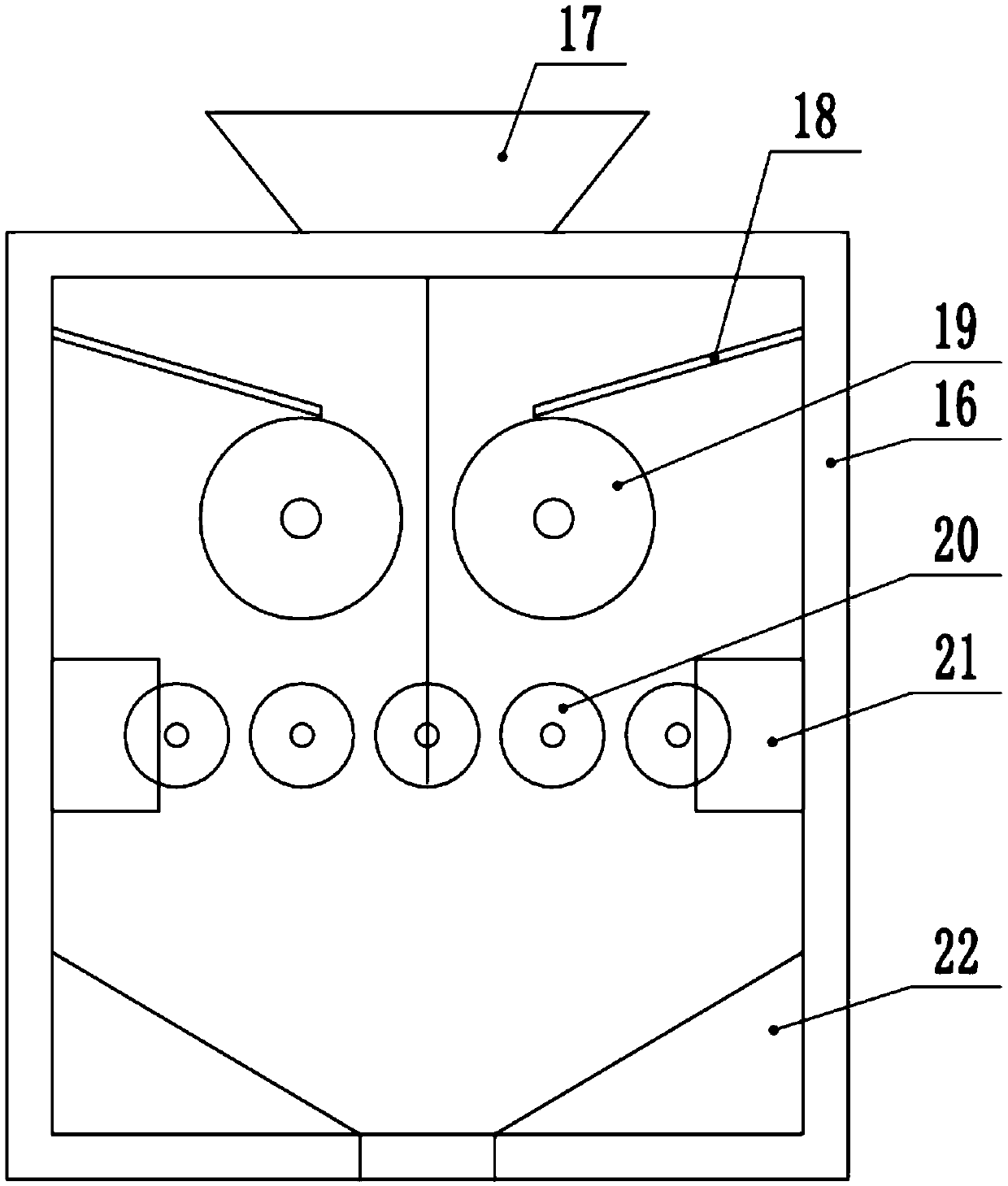

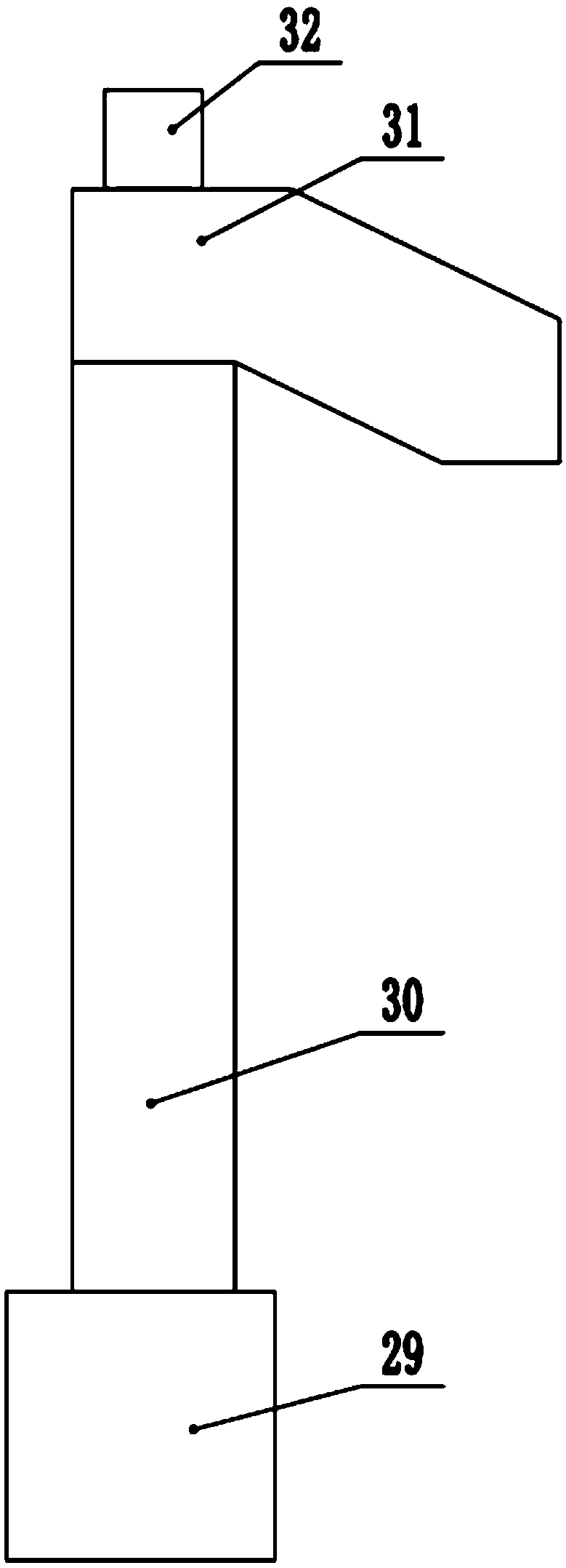

[0025] see figure 1 , a robot production line for producing organic fertilizers, comprising a crushing device 1, a first mixing box 3, a drying box 8, a second mixing box 9, a storage box 13, a packaging device 14 and a lifting mechanism, the crushing device 1, the first A mixing box 3, drying box 8, second mixing box 9, material storage box 13 and packaging equipment 14 are arranged in sequence, and the lifting mechanism includes a first lifting device 5, a second lifting device 9 and a third lifting device 12, The bottom end of the crushing device 1 is fixedly connected to the first feeding pipe 2, and the other end of the first feeding pipe 2 is fixedly connected to the top of one side of the first mixing box 3, and the bottom of the first mixing box 3 The end is fixedly connected with the second feeding pipe 4, the bottom end of the second feeding pipe 4 is fixedly connected with the first lifting device 5, the first conveyor belt 6 is arranged between the first mixing box...

Embodiment 2

[0029] see figure 1 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the top of the first conveyor belt 6 is provided with a dispersing claw 7, and the dispersing claw 7 is fixedly connected with the first lifting device 5, and the packaging The side of the device 14 away from the material storage box 13 is provided with a second conveyor belt 15 .

[0030] In the implementation process of the present invention, the organic fertilizer raw material enters the pulverizing device 1 to obtain double pulverization, then enters the first mixing box 3, adds other raw materials in the first mixing box 3, starts the stirring motor for mixing and stirring, and the mixing after stirring The raw material is transported to the first conveyor belt 6 through the first lifting device 5, and the dispersing claw 7 disperses the raw material on the first conveyor belt 6 to make it evenly distributed, and then starts the hot air blower 27 to dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com