A kind of production device of sodium nitrite

A production device, sodium nitrite technology, applied in the chemical industry, can solve the problems of inability to reduce the heat load at the hot end, leakage and interconnection of heat exchange equipment, and high evaporation end temperature, so as to improve the vacuum degree of evaporation, reduce manpower and material resources, and ensure The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

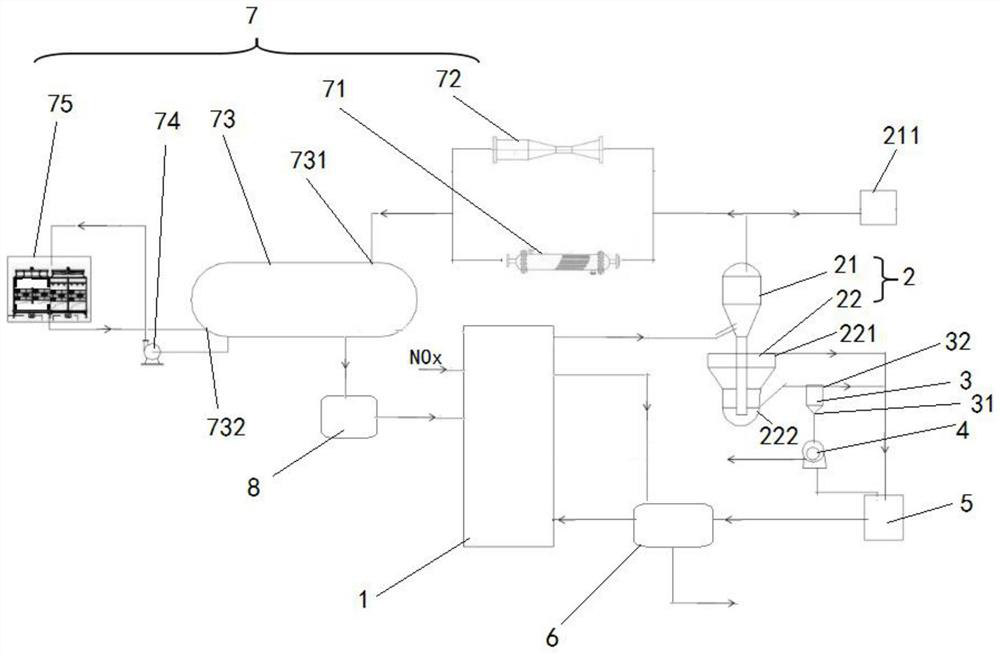

[0015] Such as figure 1 Shown, the embodiment of the present invention provides a kind of production device of sodium nitrite, comprises dissolving alkali tank 8, lye absorption tower 1, crystallizer 2, thickener 3, centrifuge 4, mother liquor tank 5, conversion tower 6, Heat exchange mechanism 7;

[0016] The crystallizer 2 includes a flash chamber 21 at the top and a crystallization chamber 22 at the bottom, the flash chamber 21 is provided with a vacuum device 211, and the entrance of the flash chamber 21 is connected with the The outlet of the lye absorption tower 1 is connected; the crystallization chamber 22 includes an overflow liquid outlet 221 positioned at the top and a crystallization liquid outlet 222 positioned at the bottom, and the crystallization liquid outlet 222 passes through the bottom outlet of the thickener 3 31 is connected to the centrifuge 4, the mother liquor outlet 41 of the centrifuge 4 is connected to the mother liquor tank, the thickener 3 is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com