Bi-material high-resiliency diaphragm

A high-resilience, diaphragm technology, applied in the field of filter press diaphragms, can solve the problems of product scrap, cannot be reset, cannot be restored, etc., and achieve the effect of prolonging service life, not producing stress relaxation, and stable hydrolysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A double-material high-resilience diaphragm, weighing 28-40% SEBS, 20-40% white oil, 20-30% polypropylene, 8-15% high-density polyethylene, and 3-6 nanometer calcium carbonate by weight % and antioxidant 0.2-0.5%.

[0014] The beneficial effects of the present invention are: SEBS does not contain unsaturated double bonds, so it has good stability and aging resistance; polypropylene is a semi-crystalline thermoplastic; it has high impact resistance, strong mechanical properties, Resistant to a variety of organic solvents and acid and alkali corrosion; high-density polyethylene is a translucent shape with high crystallinity and a certain degree of non-polar surface; its crystallinity is 80%~90%, and the softening point is 125~135℃ , the use temperature can reach 100°C; the melting temperature is 120~160°C, it has good heat resistance and cold resistance, good chemical stability, high rigidity and toughness, good mechanical strength; dielectric properties, environmental re...

Embodiment 2

[0016] A double-material high-resilience diaphragm, which weighs SEBS33%, polypropylene 22%, high-density polyethylene 9%, nano-calcium carbonate 5% and antioxidant 0.3% by weight, mixes them all uniformly, and Put it into a twin-screw extruder, then inject 30% white oil, and extrude and granulate to obtain the core material of the high-resilience diaphragm; the SEBS uses polystyrene as the terminal segment, and polybutadiene is hydrogenated The obtained ethylene-butene copolymer is a linear three-block copolymer of the middle elastic block; the white oil is an industrial grade white oil; the polypropylene is copolymerized or homopolymerized; the antioxidant The agent is antioxidant 168 or antioxidant 1010; the nano-calcium carbonate can be replaced by talcum powder of more than 3000 mesh.

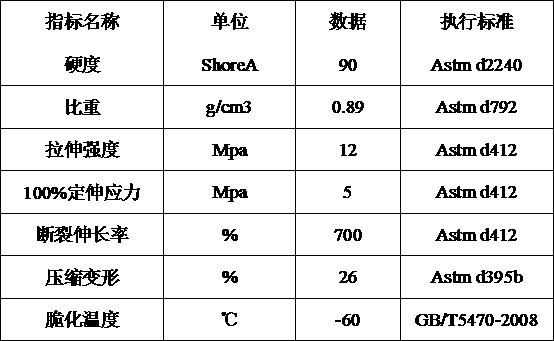

[0017] After feeding and mixing, the diaphragm core material is prepared according to the process requirements. The performance test data is as follows:

[0018]

[0019] It can be se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com