A method for ultra-refinement of martensitic structure of steel for die-casting mold

A die-casting mold and martensite technology, which is applied in heat treatment equipment, manufacturing tools, quenching agents, etc., can solve the problems of lack of in-depth consideration of quenched martensite strip refinement, limited improvement of thermal fatigue resistance of steel for die-casting molds, etc. , to achieve the effect of shortening the heat treatment cycle, reducing the heat treatment cost and improving the impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

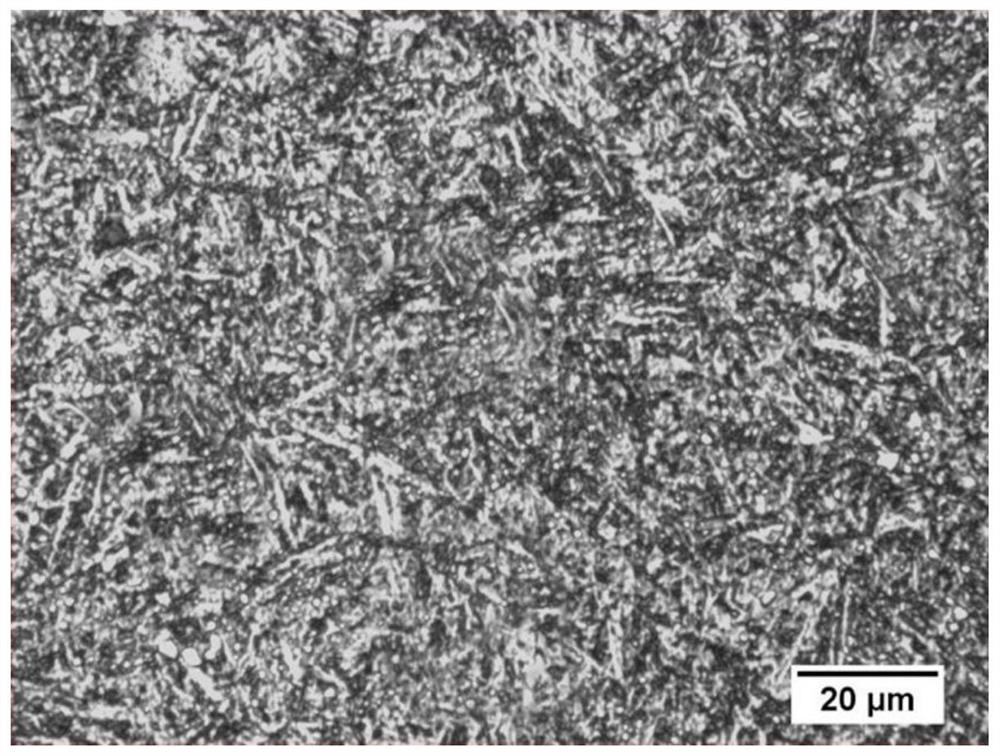

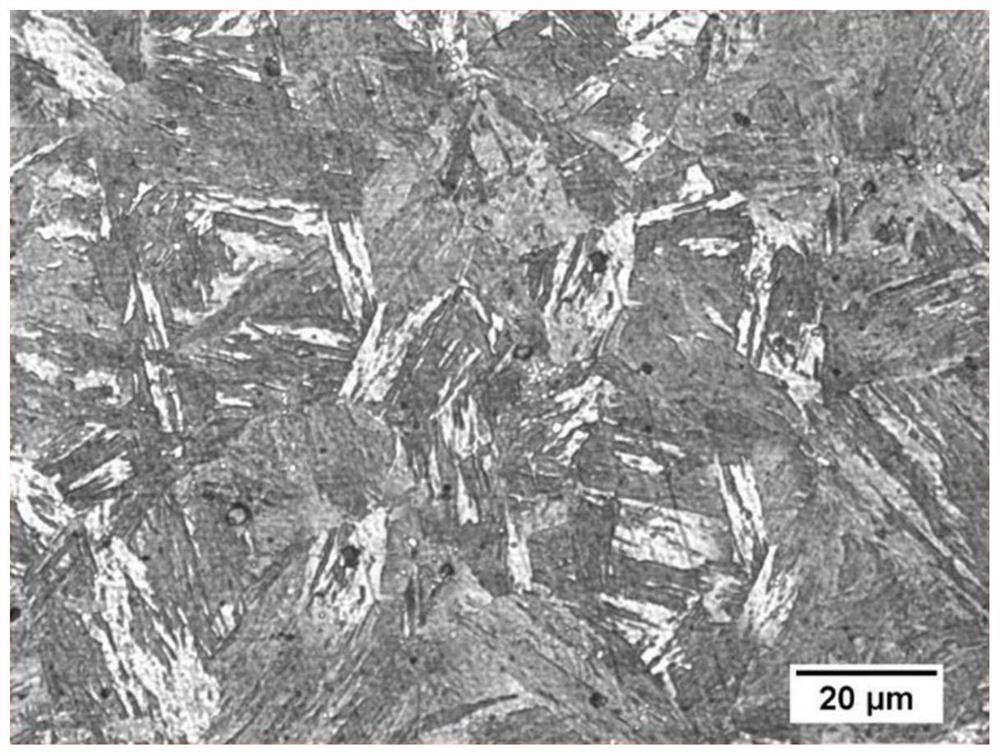

[0039] On the basis of the composition of AISI H13 steel, add 0.3wt% ~ 0.6wt% Nb (niobium), after smelting, casting, 1200 ~ 1300 ℃ high temperature diffusion annealing for 12 hours (homogenization) and after forging (forging thickness 180 ~ 240mm ), ultra-fine treatment (isothermal ultra-fine in the two-phase area, to realize the spheroidization of carbides: heat preservation at 1030°C for 15 hours, quench to room temperature, heat to 830°C and heat preservation for 3 hours, cool to 760°C, continue heat preservation for 6~ 8h / 100mm), and then perform the following martensitic superfine heat treatment:

[0040] (1) The first stage of quenching and cooling process: 1030-1050°C vacuum insulation heat treatment for 2-6 hours; gas quenching with 3-5bar nitrogen or inert gas to reduce the surface temperature of the mold steel module to 260-270°C, and Keep at this temperature for 120s, and the temperature difference between the core and the surface of the forging is controlled at 50-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com