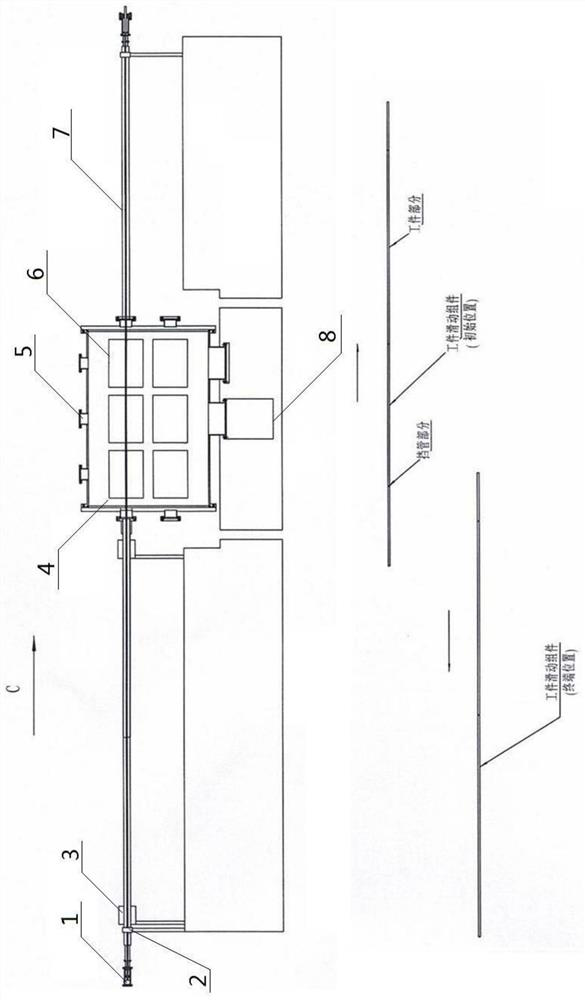

A special device for multi-station long tube high-efficiency magnetron sputtering coating

A technology of magnetron sputtering coating and special device, which is applied in the field of high-efficiency preparation of metal film materials, can solve the problems of long coating time, low coating success rate, large target size, etc. performance, achieving continuous effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

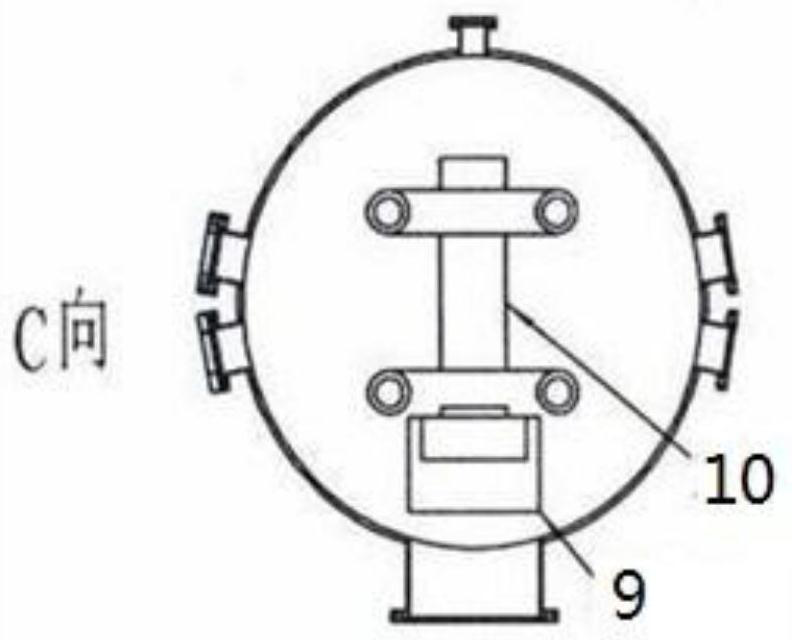

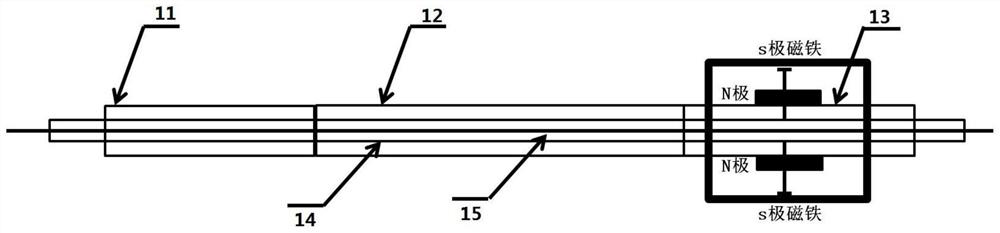

Method used

Image

Examples

Embodiment 1

[0047] Install the 304 stainless steel target in the ring target magnetron sputtering long tube coating special device, put the 1.2m coated copper tube into the equipment at the loading and unloading end of the sliding assembly of the magnetic coupling transmission system, and then seal the loading and unloading end. Start the mechanical pump to evacuate the vacuum chamber. When the vacuum reaches 8.5Pa, start the molecular pump to evacuate the vacuum chamber. At the same time, start the heating system at the core of the pipe to heat the copper pipe. Before coating, the base of the pipe The temperature is 200°C, when the vacuum reaches 5.3*10 - 3 At Pa, fill the argon gas through the charging port, adjust the power supply parameters, the sputtering voltage reaches 450V, the sputtering current reaches 1.5A, and the time for sputtering 304 stainless steel film for copper tube is 1min. During the coating process, the copper tube is moved from one end of the sputtering device to ...

Embodiment 2

[0050] Install the metal chromium target in the ring target magnetron sputtering long tube coating special device, put the 1.2m coated copper tube into the equipment at the loading and unloading end of the sliding assembly of the magnetic coupling transmission system, and then seal the loading and unloading end. Start the mechanical pump to evacuate the vacuum chamber. When the vacuum reaches 8.0Pa, start the molecular pump to evacuate the vacuum chamber. At the same time, start the heating system at the core of the pipe to heat the copper pipe. Before coating, the base of the pipe The temperature is 250°C, when the vacuum reaches 6.6*10 -3 At Pa, fill the argon gas through the charging end, adjust the power supply parameters, the sputtering voltage reaches 480V, the sputtering current reaches 1.8A, and the time for sputtering metal chromium film on copper tube is 3min. During the coating process, the copper tube is moved from one end of the sputtering device to the other end ...

Embodiment 3

[0053] Install the FeCrAl alloy target in the ring target magnetron sputtering long tube coating special device, put the 1.2m coated copper tube into the equipment at the loading and unloading end of the sliding assembly of the magnetic coupling transmission system, and then seal the loading and unloading end. Start the mechanical pump to evacuate the vacuum chamber. When the vacuum reaches 7.6Pa, start the molecular pump to evacuate the vacuum chamber. At the same time, start the heating system at the core of the pipe to heat the copper pipe. Before coating, the base of the pipe The temperature is 220°C, when the vacuum reaches 5.8*10 - 3 Pa, fill the argon gas through the gas filling port, adjust the power supply parameters, the sputtering voltage reaches 460V, the sputtering current reaches 1.6A, and the time for sputtering the FeCrAl alloy film for the copper tube is 1.5min. During the coating process, the copper tube is moved from one end of the sputtering device to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com