Cobalt vanadate and reduced graphene oxide composite negative electrode material and preparation method thereof

A graphene composite, negative electrode material technology, applied in battery electrodes, final product manufacturing, electrochemical generators and other directions, can solve problems such as difficult synthesis of nanoparticle and graphene composite materials, unfavorable large-scale production, and few synthesis methods. , to achieve the effects of excellent cycle stability and rate performance, shortened production cycle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

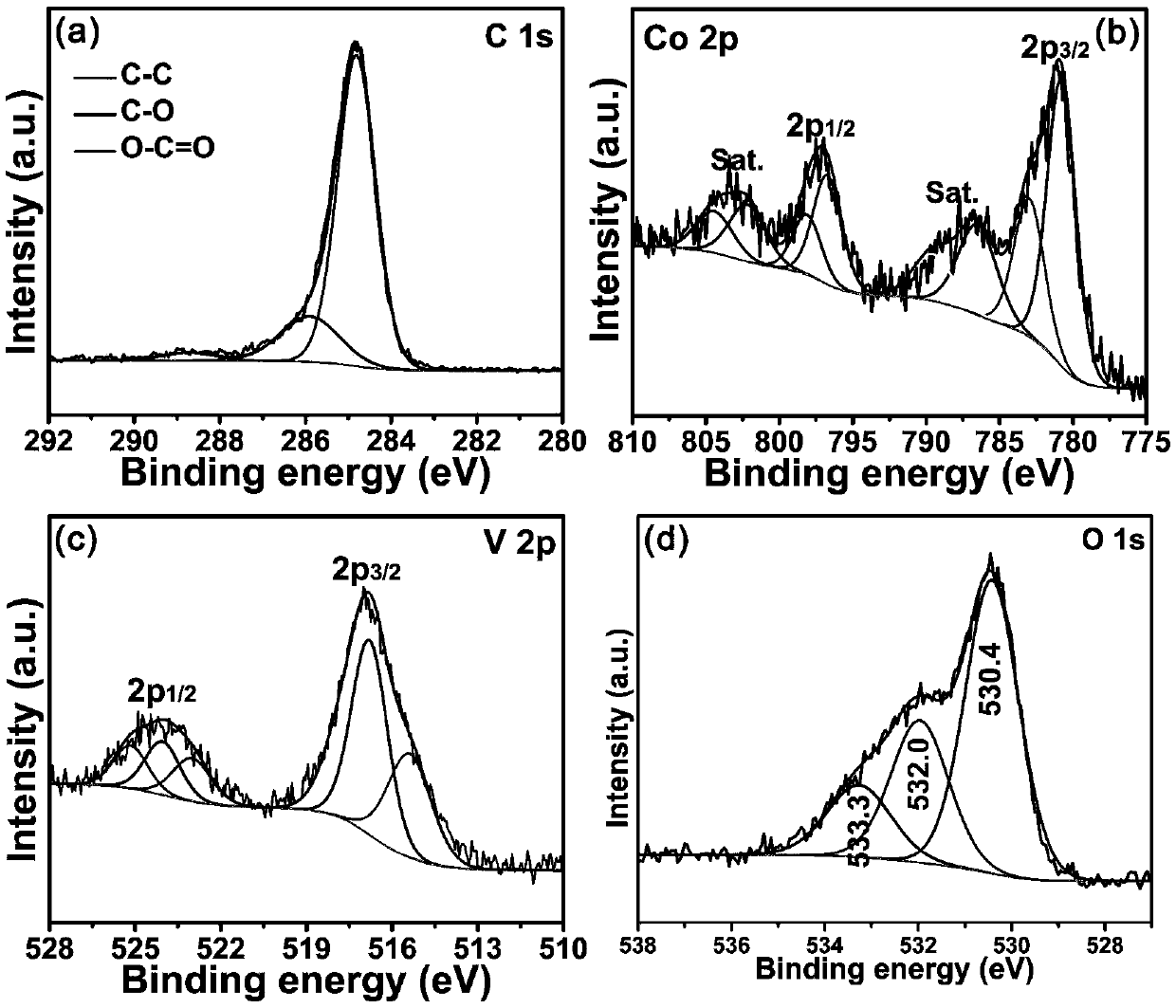

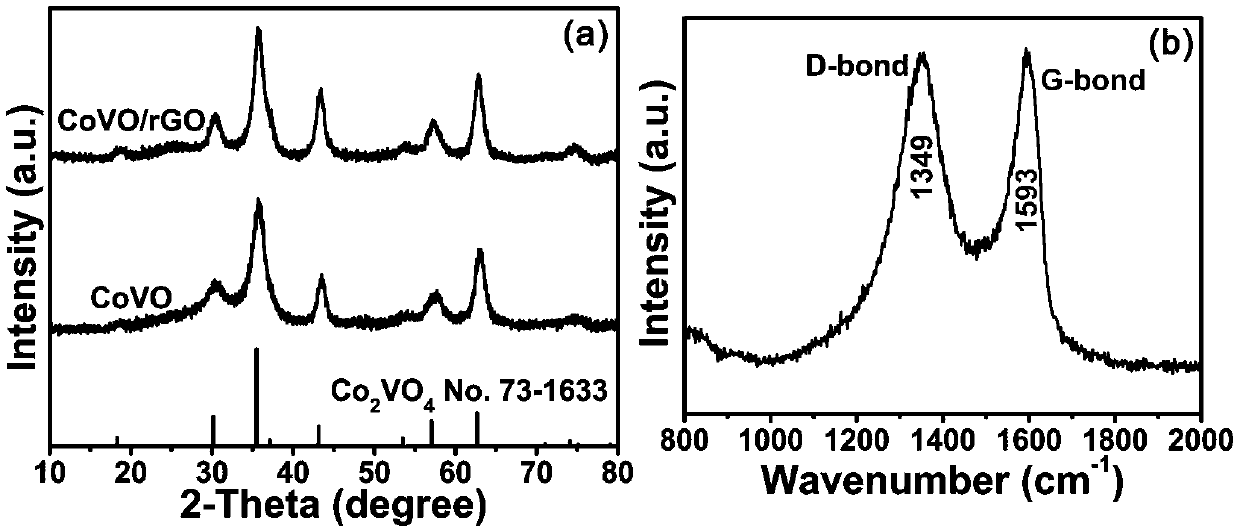

[0040] The cobalt vanadate and reduced graphene oxide composite negative electrode material prepared by the preparation method of the present invention is characterized in that the cobalt vanadate and reduced graphene oxide composite negative electrode material is Co 1.8 V 1.2 o 4 Lithium-ion battery anode material composited with reduced graphene oxide.

[0041] The method for preparing a lithium battery from the cobalt vanadate and reduced graphene oxide composite negative electrode material of the present invention: mix the cobalt vanadate and reduced graphene oxide composite negative electrode material with 20% conductive agent, and then mix with 10% binder Mix the N-methylpyrrolidone solution, stir evenly, apply it on the copper foil, put it in a vacuum oven and dry it at 100°C; then use a slicer with a diameter of 14mm to cut out the electrode piece, put it in a vacuum oven and dry it at 80°C for 6 ~12h; then transferred to a glove box filled with argon, with metal lit...

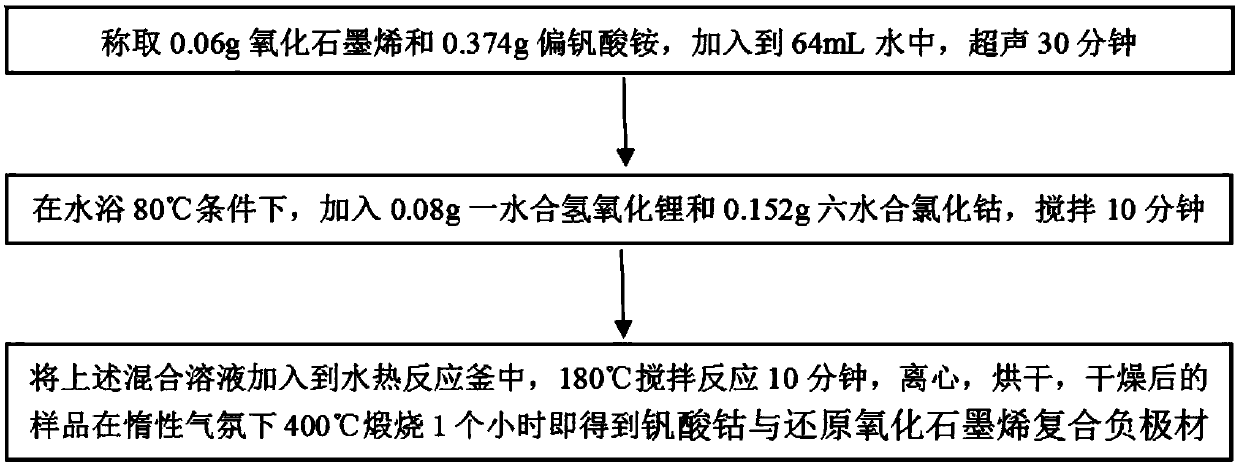

Embodiment 1

[0045] Weigh 0.06g of graphene oxide and 0.374g of ammonium metavanadate, add them into 64mL of water, ultrasonicate for 30 minutes, and add 0.08g of lithium hydroxide monohydrate and 0.152g of cobaltous chloride hexahydrate in a water bath at 80°C, and stir for 10 Minutes, the above mixed solution was added to the hydrothermal reaction kettle, stirred and reacted at 180°C for 10 minutes, centrifuged, dried, and the dried sample was calcined at 400°C for 1 hour under an inert atmosphere to obtain cobalt vanadate and reduced graphene oxide Composite anode materials.

[0046] Implementation effect: the novel Co prepared in this embodiment 1.8 V 1.2 o 4 Assembled with the reduced graphene oxide composite anode material to form a battery for charge and discharge tests, Figure 5 (c) is a cycle performance diagram of a lithium-ion battery assembled at a current density of 100mA / g and a voltage range of 3-0.01V. It can be seen that the first discharge capacity is 1199mAh / g, the ...

Embodiment 2

[0048] Weigh 0.374g of ammonium metavanadate, add it into 64mL of water, ultrasonicate for 30 minutes, add 0.08g of lithium hydroxide monohydrate and 0.152g of cobalt chloride hexahydrate in a water bath at 80°C, stir for 10 minutes, and dissolve the above mixed solution Add it into a hydrothermal reaction kettle, stir and react at 180°C for 10 minutes, centrifuge, dry, and calcinate the dried sample at 400°C for 1 hour under an inert atmosphere to obtain the cobalt vanadate negative electrode material.

[0049] Implementation effect: the new cobalt vanadate negative electrode material prepared in this example is assembled into a battery for charge and discharge test, and the charge and discharge test is carried out at a current density of 100mA / g. The first discharge capacity is 1701mAh / g, and the cycle is 100 The remaining discharge capacity after one cycle is only 112mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com