A kind of structured silica gel adsorption material and preparation method thereof

A technology of structured silica gel and adsorption materials, which is applied in chemical instruments and methods, inorganic chemistry, and other chemical processes, and can solve problems such as low overall strength of adsorption materials, low strength and hardness of matrix materials, and unsuitable distribution of silica gel layers. Achieve the effects of easy modular filling, long service life, and high surface activity channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

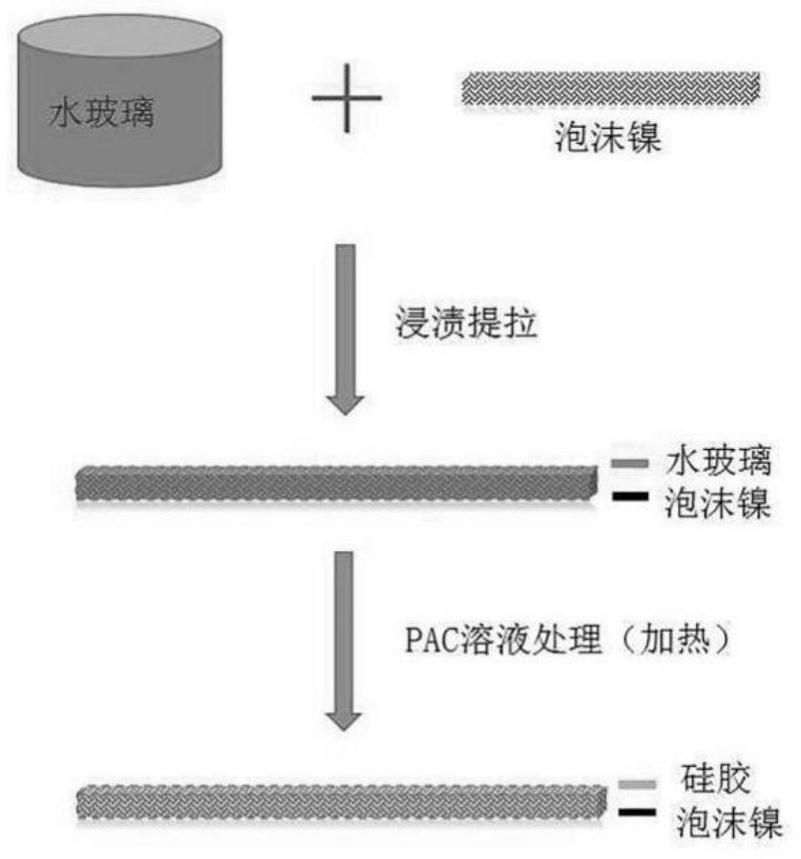

[0027] Embodiment 1: A kind of preparation method of structured silica gel adsorption material:

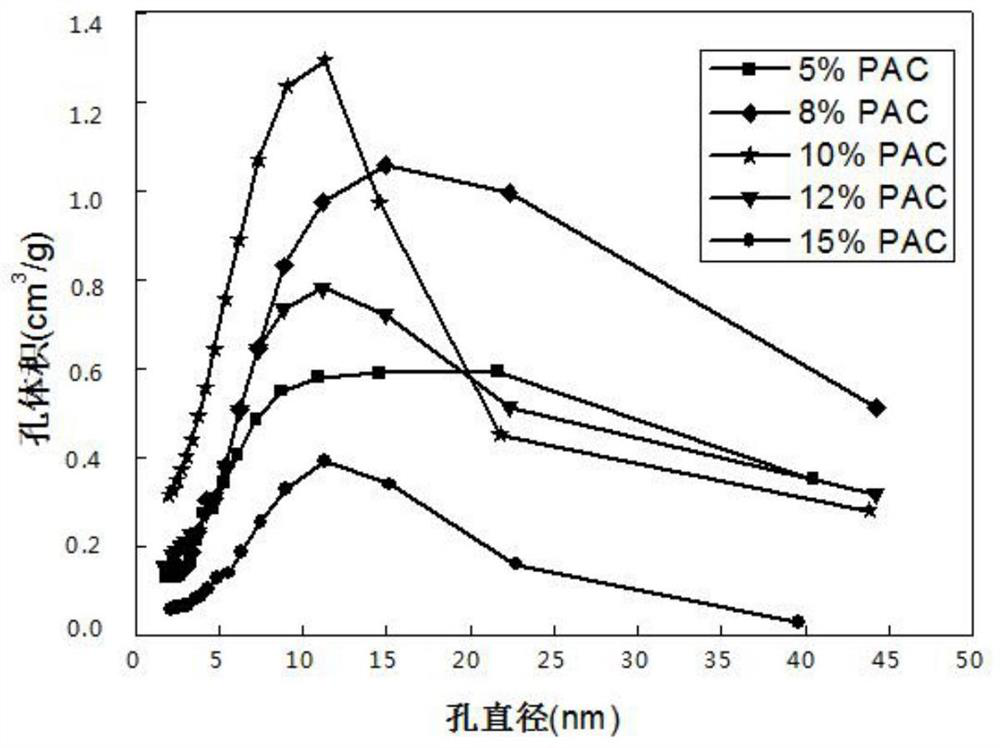

[0028] Soak a three-dimensional nickel foam sheet with a pore size of 0.1mm, a thickness of 0.6mm, and a porosity of 92% in a silane solution with a mass fraction of 2%, remove the residual liquid, dry it and cure it at 100°C for 1 hour, and dry the dried sample Then soak into the silica sol solution with a mass fraction of 20%, and pre-coat a layer of silica gel film. The program-controlled pulling machine was set at a pulling speed of 2 cm / min, a drying time of 15 min, and dip-coated 5 times to obtain a sample coated with water glass. After drying at room temperature for 15 minutes, soak it in a PAC solution with a heating temperature of 45°C and a mass fraction of 5%, take it out after 2 hours, rinse it with deionized water, and bake it at 120°C for 2 hours. Place in acetone solution and pass through an ultrasonic oscillator for 30 minutes, and the mass loss rate is 1.5%.

Embodiment 2

[0029] Embodiment 2: A kind of preparation method of structured silica gel adsorption material:

[0030] Soak a three-dimensional structure nickel foam sheet with a pore size of 0.5mm, a thickness of 2mm, and a porosity of 85% in a silane solution with a mass fraction of 5%, remove the residual liquid, dry it and cure it at 100°C for 2 hours, and dry the dried sample again. Immerse in a silica sol solution with a mass fraction of 30%, and pre-coat a layer of silica gel film. The program-controlled pulling machine was set at a pulling speed of 2 cm / min, a drying time of 15 min, and dip-coated 7 times to obtain a sample coated with water glass. After drying at room temperature for 30 minutes, soak it in a PAC solution with a heating temperature of 60°C and a mass fraction of 10%, take it out after 1 hour, rinse it with deionized water, and bake it at 100°C for 3 hours. Placed in acetone solution and subjected to an ultrasonic oscillator for 30 minutes, the mass loss rate was 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com