Metal oxide/carbon material compound as well as preparation method and application thereof

A technology of oxides and carbon materials, applied in the field of electrochemistry, can solve the problems of difficult biodegradation, easy passivation, high concentration, etc., and achieve the effects of good electrocatalytic performance, abundant active sites, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

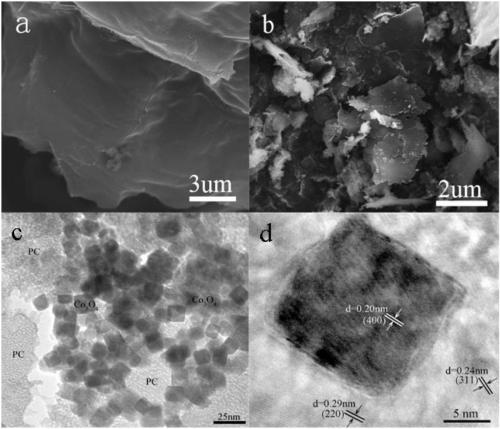

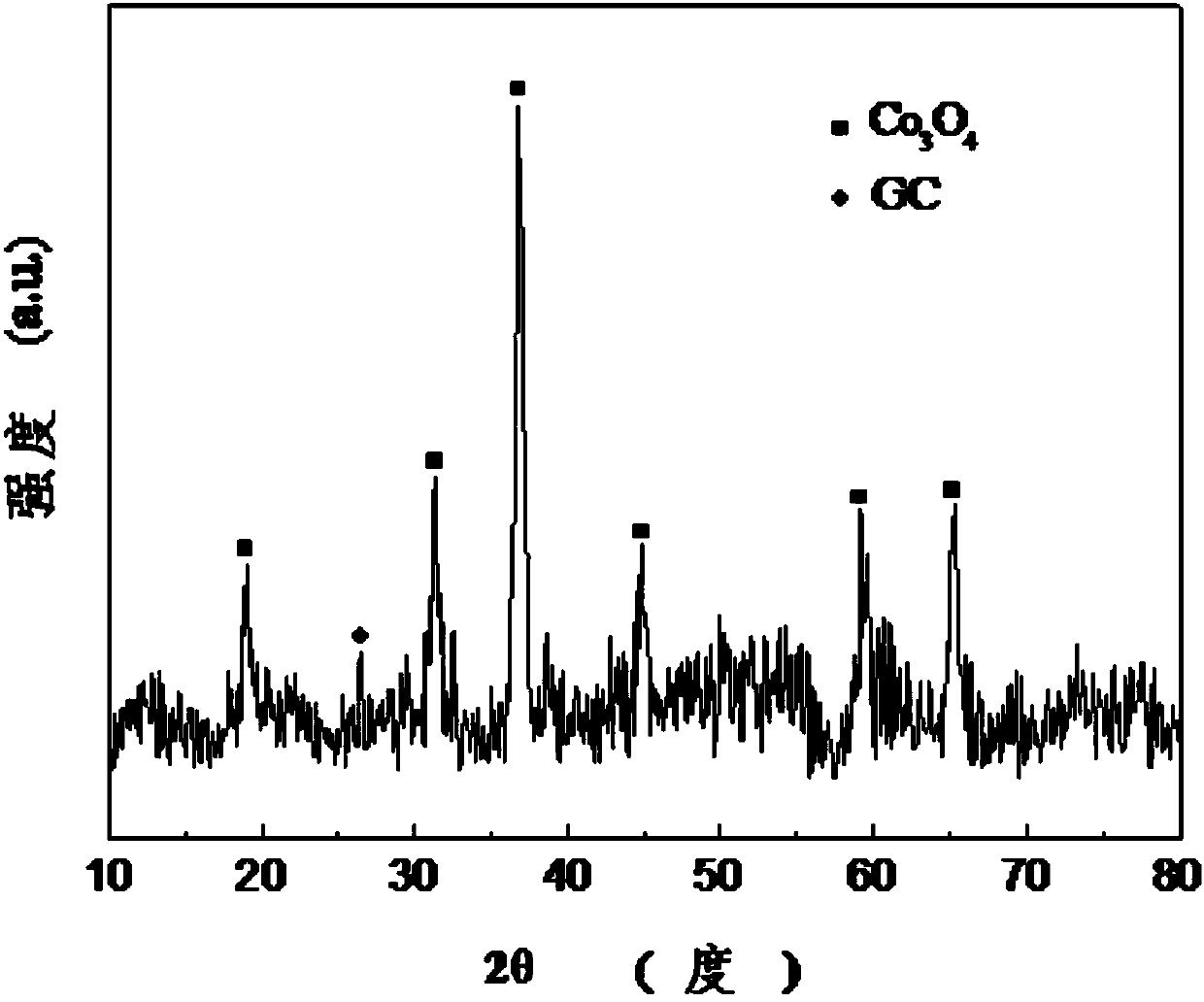

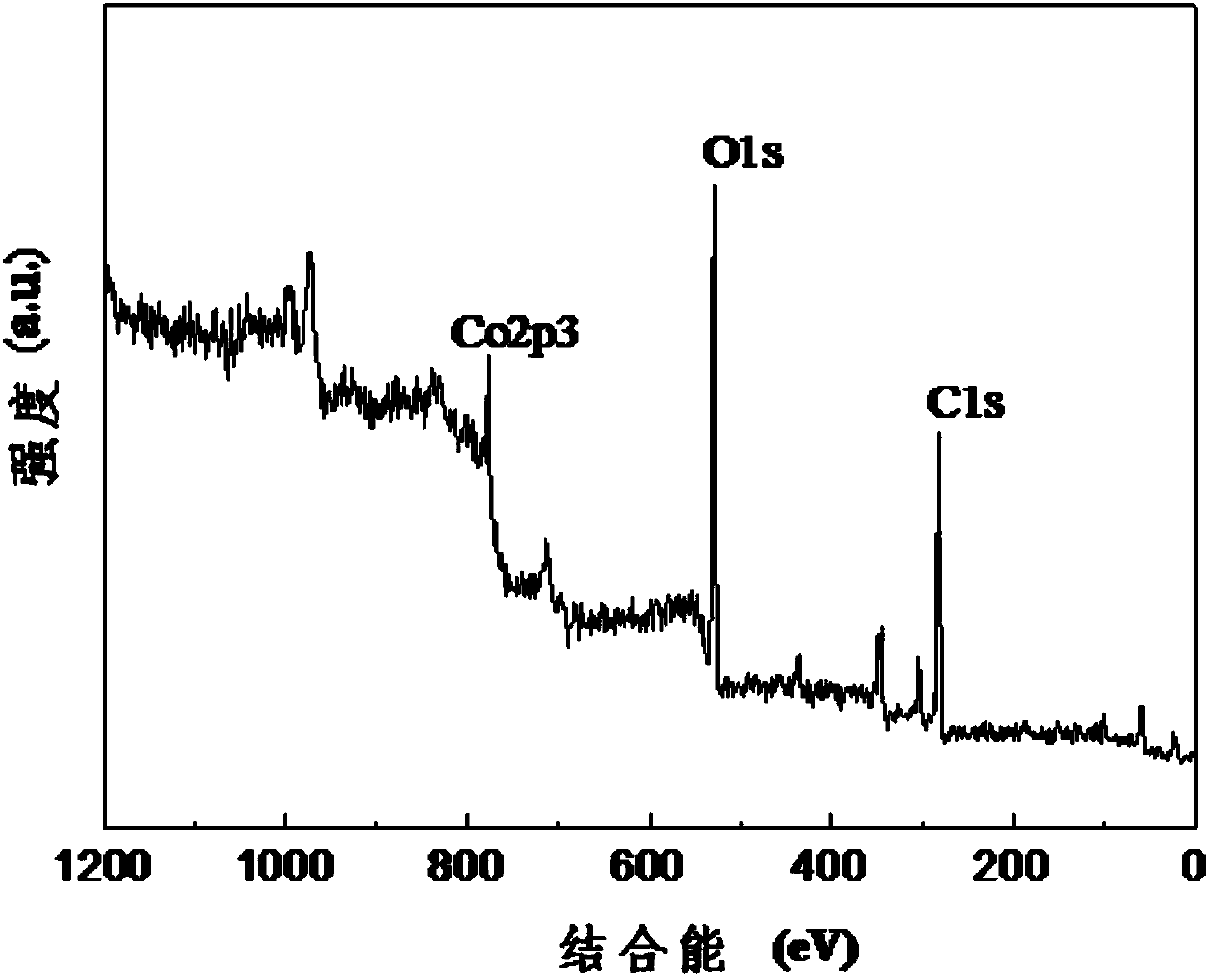

Image

Examples

Embodiment 1

[0127] Peel off the outer skin of the pomelo peel, save the spongy part in the middle, cut the part into small pieces, wash with deionized water, and dry in an oven at 80°C for later use;

[0128] Put the spare pomelo peel in a tubular muffle furnace, raise the temperature to 500°C at a heating rate of 5°C / min under the protection of nitrogen and keep it warm for 1h for pre-carbonization treatment, N 2 The flow rate is 60mL / min;

[0129] Wash the pre-carbonized carbon material with deionized water, dry it in an oven at 100 ° C, and then mix and impregnate it with KOH concentrated solution (concentration: 30%) at a mass ratio of 1:1.5, fully Place it for 24 hours after mixing;

[0130] The mixed material was dried in an oven at 100°C and then baked in a tubular muffle furnace at a firing temperature of 800°C with a heating rate of 5°C min –1 , the roasting time is 1h;

[0131] The activated sample uses 0.1mol L –1 The hydrochloric acid solution neutralizes the residual hydr...

Embodiment 2~5

[0139] The method used in Examples 2 to 5 is similar to that of Example 1, the difference is only that the added CoCl 2 ·6H 2 O is 0.01g, 0.03g, 0.07g and 0.09g respectively, the Co in the obtained complex 3 o 4 The contents are 1%, 3%, 7% and 9% respectively.

Embodiment 6~9

[0141] The method used in Examples 6-7 is similar to that of Example 1, the only difference being that the final sample is calcined and purified in a muffle furnace to obtain Co 3 o 4 / PC composites, the calcination temperatures were 350°C, 400°C, 500°C and 550°C, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com