Catalyst for diesel engine on basis of composite main catalyst and hydrotalcite-derived oxide and preparation method thereof

A composite oxide, main catalyst technology, used in chemical instruments and methods, molecular sieve catalysts, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

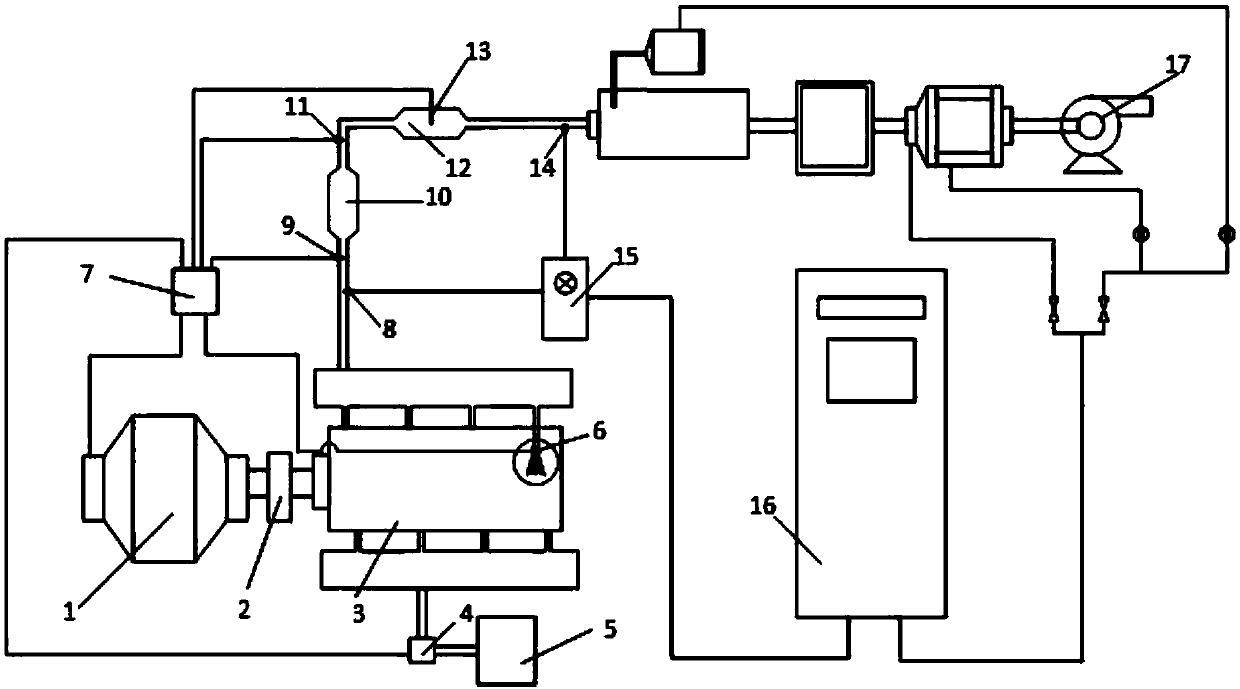

Image

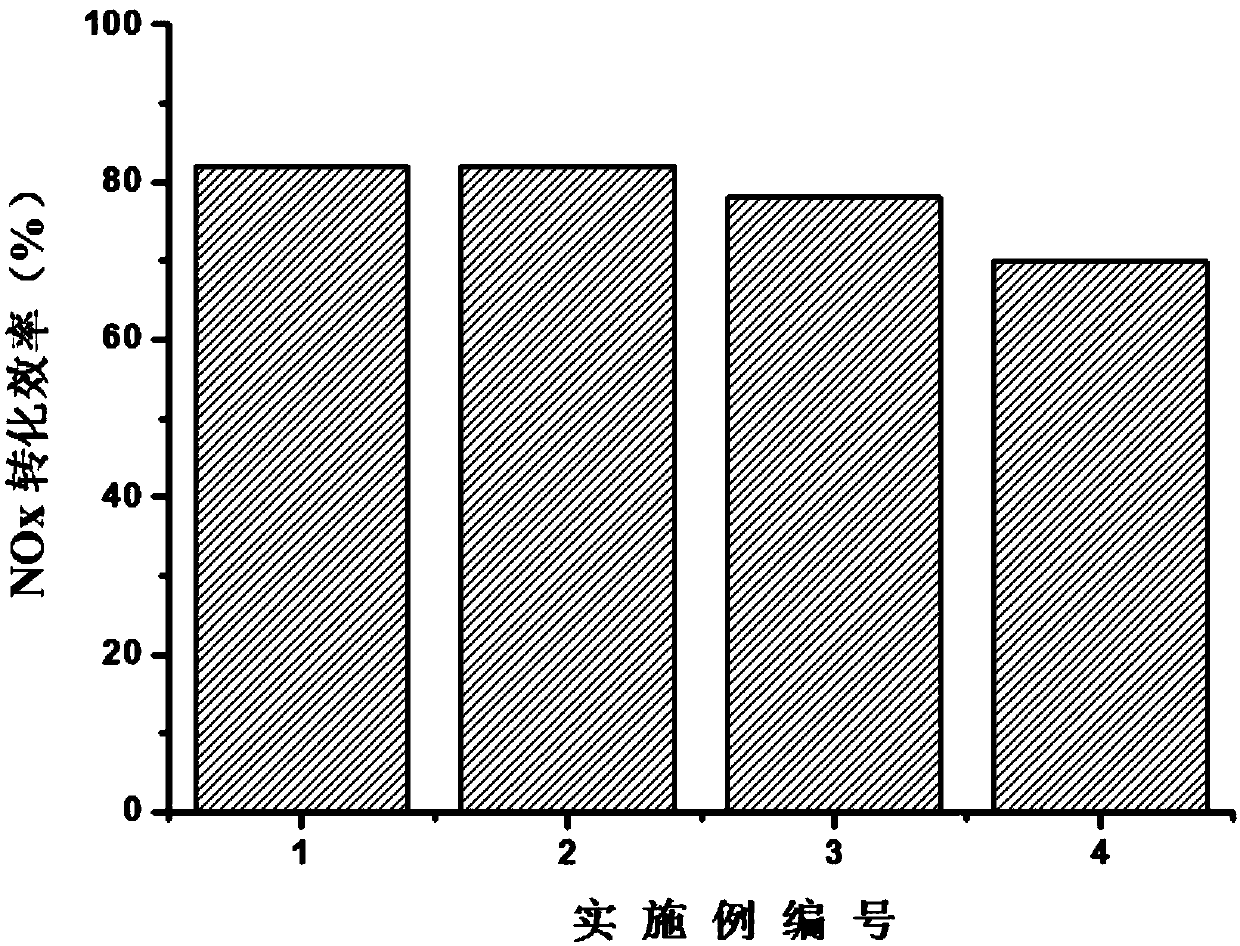

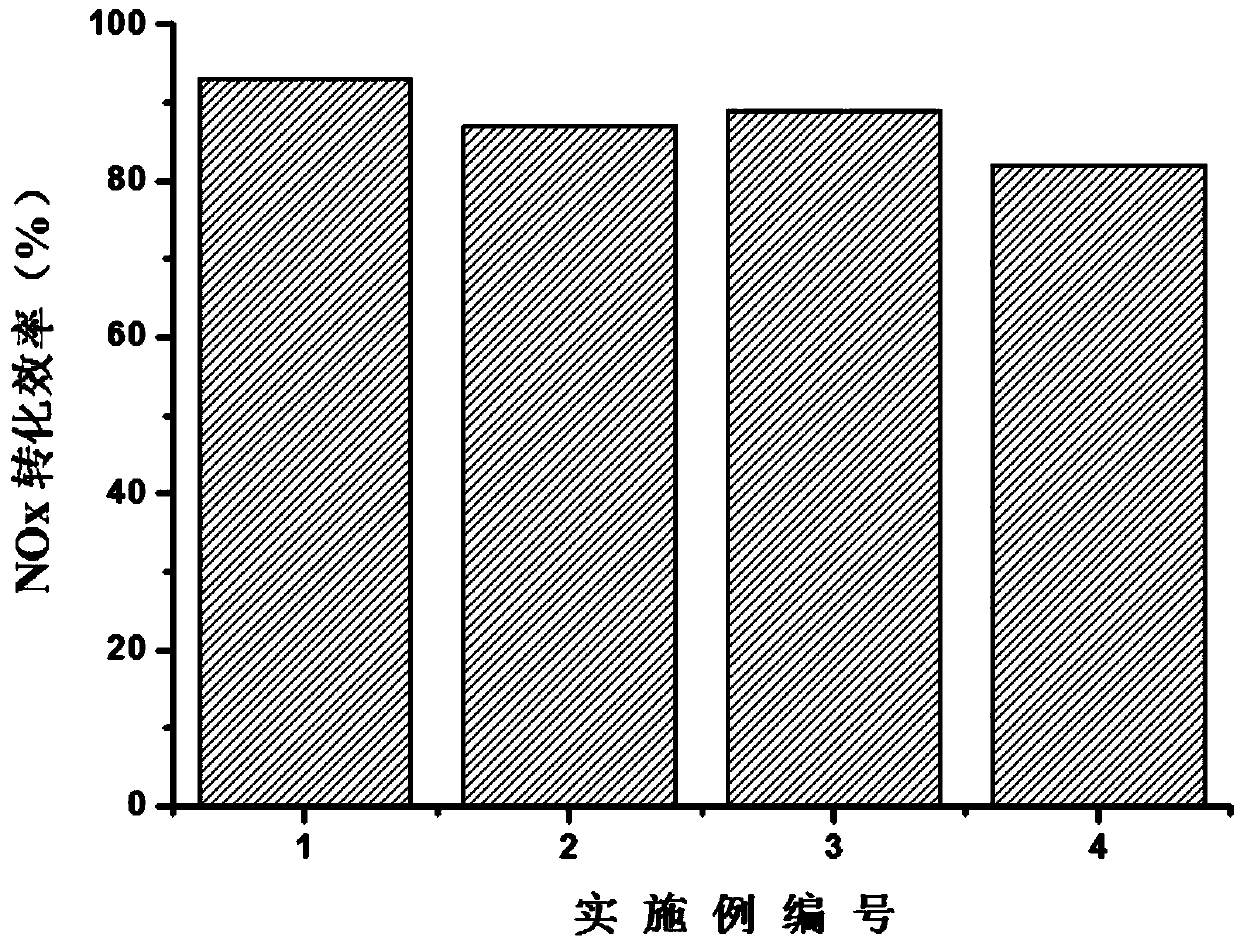

Examples

Embodiment 1

[0040] (1) Determination of the amount of catalyst raw material used

[0041] La in the main catalyst of the prepared catalyst of Design Example 1 x Ce (1-x) mn y Fe (1-y) o 3 The mass ratio of type perovskite composite oxide and Cr modified ZSM-5 molecular sieve is: 75%:25%; La x Ce (1-x) mn y Fe (1-y) o 3 In the type perovskite composite oxide, the molar percentage of La ion and Ce ion at A site is: 25% / 75%, and the molar percentage of Mn ion and Fe ion at B site is: 50% / 50%; Cr modified ZSM -5 molecular sieve, Cr 2 o 3 The mass percentage of the ZSM-5 molecular sieve is: 15% / 85%; the mass ratio of the main catalyst, co-catalyst and coating base material is: 15%: 20%: 65%; CeO in the co-catalyst 2 and ZrO 2 The mass ratio is: 60%:40%; Ni-modified hydrotalcite derived composite oxide and γ-Al in the coating base material 2 o 3 The mass ratio of MgO and NiO is: 80%: 20%; The mass ratio of MgO and NiO in the Ni modified hydrotalcite derived composite oxide is: 15%...

Embodiment 2

[0054] (1) Determination of the amount of catalyst raw material used

[0055] La in the main catalyst of the prepared catalyst of design embodiment 2 x Ce (1-x) mn y Fe (1-y) o 3 The mass ratio of type perovskite composite oxide and Cr modified ZSM-5 molecular sieve is: 50%:50%; La x Ce (1-x) mn y Fe (1-y) o 3 In the type perovskite composite oxide, the molar percentage of La ion and Ce ion at A site is: 75% / 25%, and the molar percentage of Mn ion and Fe ion at B site is: 25% / 75%; Cr modified ZSM -5 molecular sieve, Cr 2 o 3 The mass percentage of ZSM-5 molecular sieve is: 5% / 95%; the mass ratio of main catalyst, co-catalyst and coating base material is: 8%: 10%: 82%; CeO in co-catalyst 2 and ZrO 2 The mass ratio is: 80%:20%; Ni-modified hydrotalcite-derived composite oxide and γ-Al in the coating base material 2 o 3 The mass ratio of MgO and NiO is: 90%: 10%; The mass ratio of MgO and NiO in the Ni modified hydrotalcite derived composite oxide is: 35%: 65%; Every ...

Embodiment 3

[0068] (1) Determination of the amount of catalyst raw material used

[0069] La in the main catalyst of the prepared catalyst of design embodiment 3 x Ce (1-x) mn y Fe (1-y) o 3 The mass ratio of type perovskite composite oxide and Cr modified ZSM-5 molecular sieve is: 50%:50%; La x Ce (1-x) mn y Fe (1-y) o 3 In the type perovskite composite oxide, the molar percentage of La ion and Ce ion at A site is: 50% / 50%, and the molar percentage of Mn ion and Fe ion at B site is: 50% / 50%; Cr modified ZSM -5 molecular sieve, Cr 2 o 3 The mass percentage of the ZSM-5 molecular sieve is: 10% / 90%; the mass ratio of the main catalyst, co-catalyst and coating base material is: 15%:15%:70%; CeO in the co-catalyst 2 and ZrO 2 The mass ratio is: 80%:20%; Ni-modified hydrotalcite-derived composite oxide and γ-Al in the coating base material 2 o 3 The mass ratio of MgO and NiO is: 90%: 10%; The mass ratio of MgO and NiO in the Ni modified hydrotalcite derived composite oxide is: 35...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com