A Welding Method of Kovar Alloy and Titanium Alloy Based on Silver Intermediate Layer

A welding method and titanium alloy technology, which is applied in the field of material welding, can solve the problems of multi-application limitations and high assembly requirements, and achieve the effects of excellent mechanical properties, low assembly requirements, and grain refinement and reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

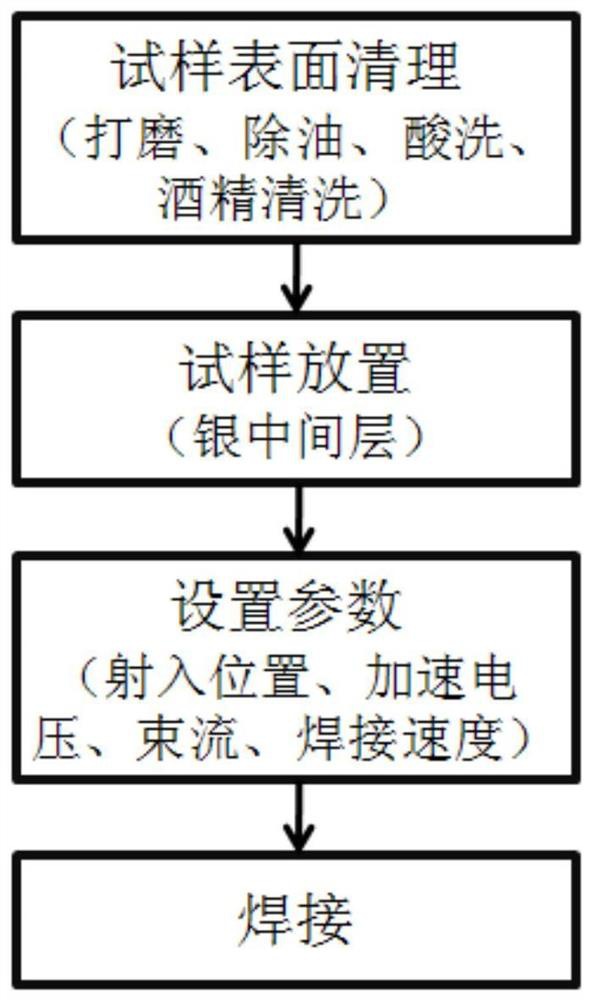

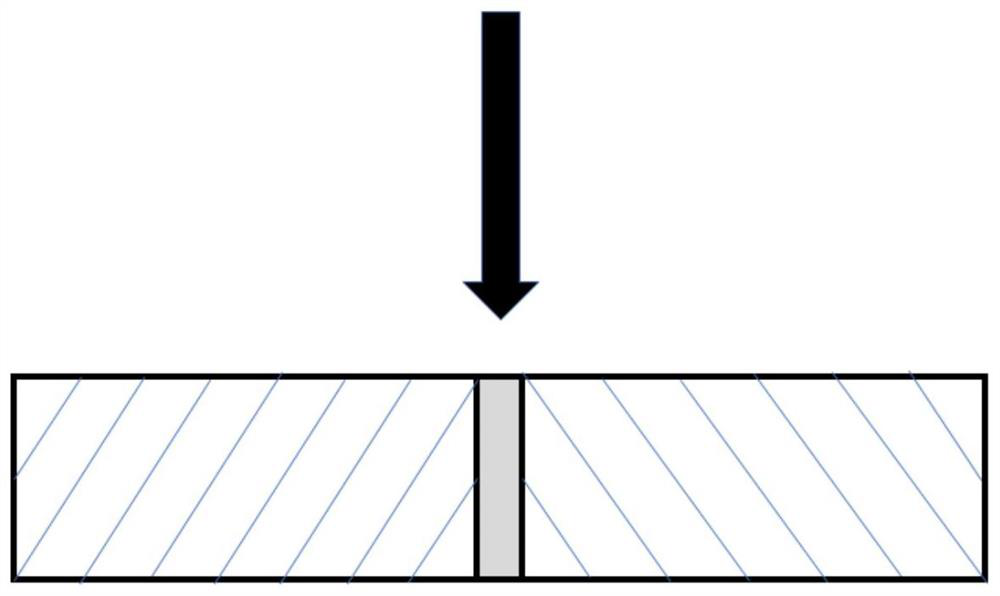

[0019] Use 4J29 Kovar alloy, TC4 titanium alloy and silver foil samples with a purity of 99wt%, grind the surface of the sample to be welded, and put the polished sample into acetone or sodium carbonate solution for ultrasonic cleaning for 15 minutes. For Kovar alloy, use 20% sulfuric acid solution to remove the oxide film, and then ultrasonic cleaning with alcohol for 5 minutes, for titanium alloy and silver, use a mixed solution of hydrofluoric acid and nitric acid to remove the oxide film, and then ultrasonic cleaning with alcohol for 5 minutes. Place the 0.8mm thick silver foil between the Kovar alloy and the titanium alloy, fix it with a clamp, and clamp it. When clamping the sample, control the maximum gap between the adjacent sample materials to not exceed 0.1mm, specifically as follows figure 2 As shown, the welding surfaces of Kovar alloy, titanium alloy and silver foil are on the same plane. The fixed sample is placed in the vacuum chamber of the vacuum electron bea...

Embodiment 2

[0021] The same sample cleaning and placement method as in Example 1 was used to weld the Kovar alloy and the titanium alloy. The thickness of the silver foil is 0.5mm, the accelerating voltage is 55kV, the electron beam current is 8mA, and the welding speed is 6mm / s. The injection position of the electron beam is located in the middle of the silver foil, and the welding starts when the vacuum degree of the welding chamber is higher than 0.1Pa. After welding, wait for the sample to cool down, then open the vacuum chamber of the welding machine, take out the sample, and obtain a composite component of Kovar alloy and titanium alloy. The flat butt welds obtained by using the above welding specifications are well formed, and there are no defects such as cracks, incomplete penetration and incomplete fusion inside the welds, no visible inclusions, and no pores.

Embodiment 3

[0023] The same sample cleaning and placement method as in Example 1 was used to weld the Kovar alloy and the titanium alloy. The thickness of the silver foil is 0.4mm, the accelerating voltage is 45kV, the electron beam current is 7mA, and the welding speed is 5mm / s. The injection position of the electron beam is located in the middle of the silver foil, and the welding starts when the vacuum degree of the welding chamber is higher than 0.1Pa. After welding, wait for the sample to cool down, then open the vacuum chamber of the welding machine, take out the sample, and obtain a composite component of Kovar alloy and titanium alloy. The flat butt welds obtained by using the above welding specifications are well formed, and there are no defects such as cracks, incomplete penetration and incomplete fusion inside the welds, no visible inclusions, and no pores.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com