Low-reflectivity high-shielding gradient structure foam material

A foam material, gradient structure technology, applied in layered products, metal layered products, chemical instruments and methods, etc., can solve the problems of secondary pollution of electromagnetic waves, impedance mismatch, etc., to reduce electromagnetic wave reflection, conductivity and electromagnetic waves. Stable shielding performance and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

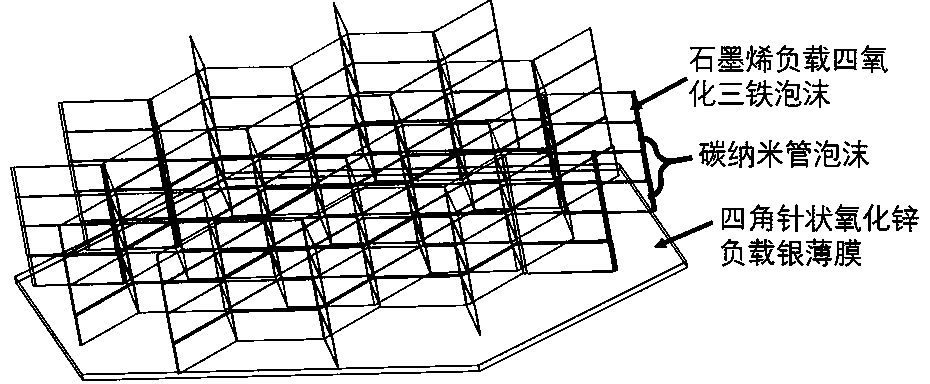

[0029] Embodiment one: the preparation method of water-based polyurethane / graphene loaded ferric oxide nanoparticles / carbon nanotubes / square needle-shaped zinc oxide whisker nanoparticles loaded silver electromagnetic shielding composite foam material, comprising the following steps:

[0030] (1) preparation of graphene-supported ferric oxide nanoparticles, including:

[0031] Weigh 20ml of graphene oxide dispersion (20mg graphene oxide), ultrasonically disperse for 30min; dissolve 90mg of ferric chloride and 60mg of ferrous sulfate in water, add to the graphene oxide dispersion; place the mixture at 50°C In a water bath, add 2ml of ammonia water dropwise, react for 2h, add 2ml of hydrazine hydrate, and react for 8h to obtain graphene-loaded ferric oxide nanoparticles.

[0032] (2) The tetragonal acicular zinc oxide whisker-loaded silver nanoparticles were prepared by chemical deposition method, wherein the silver content was 50wt%, and the conductivity of the nanoparticles wa...

Embodiment 2

[0038] Embodiment two: the preparation method of water-based polyurethane / graphene loaded ferric oxide nanoparticles / carbon nanotubes / square needle-shaped zinc oxide whisker nanoparticles loaded silver electromagnetic shielding composite foam material, comprising the following steps:

[0039] (1) preparation of graphene-supported ferric oxide nanoparticles, including:

[0040] Weigh 20ml of graphene oxide dispersion (20mg graphene oxide), ultrasonically disperse for 30min; dissolve 90mg of ferric chloride and 60mg of ferrous sulfate in water, add to the graphene oxide dispersion; place the mixture at 50°C In a water bath, add 2ml of ammonia water dropwise, react for 2h, add 2ml of hydrazine hydrate, and react for 8h to obtain graphene-loaded ferric oxide nanoparticles.

[0041] (2) The tetragonal acicular zinc oxide whisker-loaded silver nanoparticles were prepared by chemical deposition method, wherein the silver content was 50wt%, and the conductivity of the nanoparticles wa...

Embodiment 3

[0047] Embodiment three: the preparation method of water-based polyurethane / graphene loaded ferric oxide nanoparticles / carbon nanotubes / square needle-shaped zinc oxide whisker nanoparticles loaded silver electromagnetic shielding composite foam material, comprising the following steps:

[0048] (1) preparation of graphene-supported ferric oxide nanoparticles, including:

[0049] Weigh 20ml of graphene oxide dispersion (20mg graphene oxide), ultrasonically disperse for 30min; dissolve 90mg of ferric chloride and 60mg of ferrous sulfate in water, add to the graphene oxide dispersion; place the mixture at 50°C In a water bath, add 2ml of ammonia water dropwise, react for 2h, add 2ml of hydrazine hydrate, and react for 8h to obtain graphene-loaded ferric oxide nanoparticles.

[0050] (2) The tetragonal acicular zinc oxide whisker-loaded silver nanoparticles were prepared by chemical deposition method, wherein the silver content was 50wt%, and the conductivity of the nanoparticles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com