Multi-layer composite board

A composite board and adhesive layer technology, applied in the direction of layered products, synthetic resin layered products, wood treatment details, etc., can solve the problem of reducing the quality of foam sheet products, insufficient melt to cover air bubbles, and connection of connectors In order to solve the problem of low stability, achieve good toughness, improve efficiency, and enhance connection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

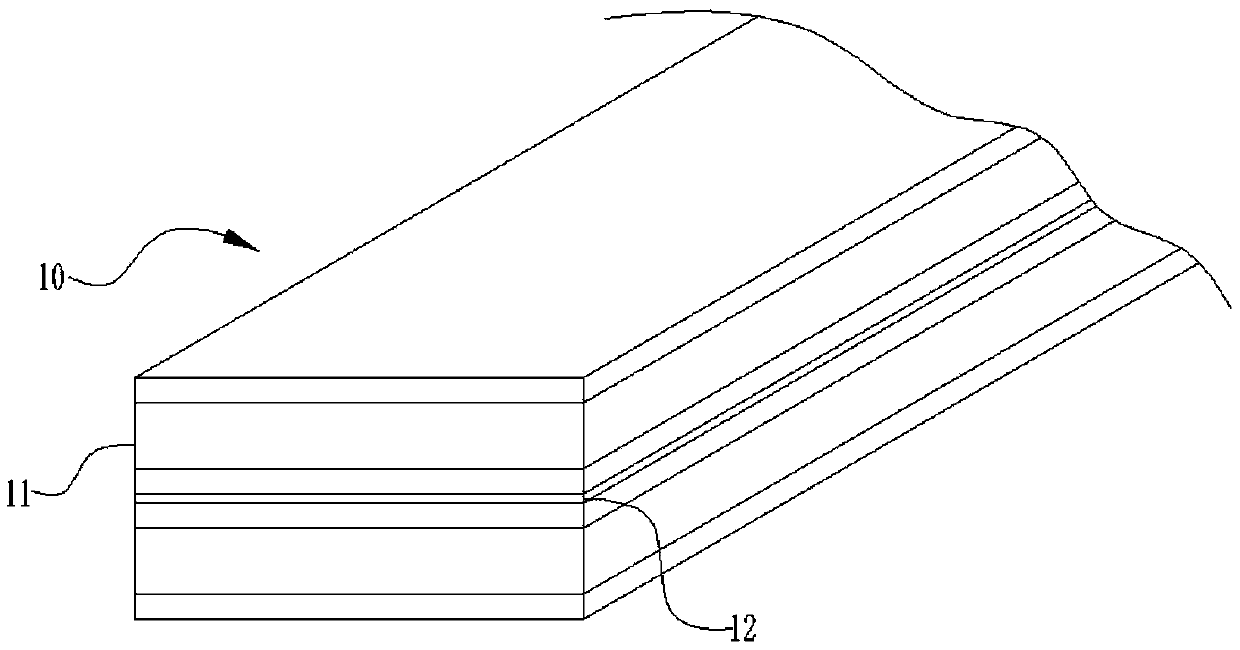

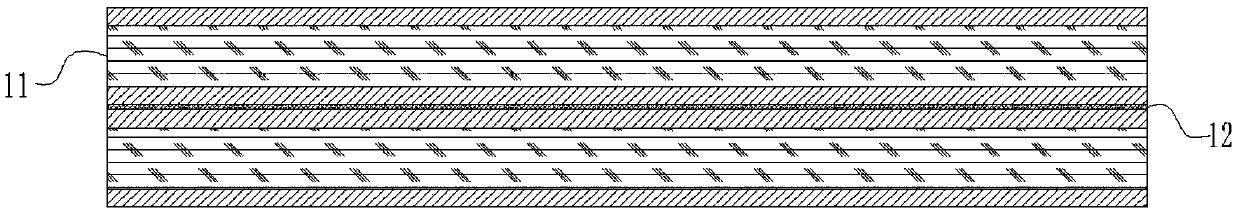

[0037] Such as figure 1 and figure 2Shown: a kind of multi-layer composite board, comprises two PVC crust foam boards 11 and adhesive layer 12, and adhesive layer 12 is formed between PVC crust foam boards 11, and is bonded via adhesive layer 12 The bonding effect makes the PVC crust foam board 11 bonded to form a multi-layer composite board 10; the PVC crust foam board 11 includes a PVC foam board layer and a skin layer located on the upper and lower surfaces of the PVC foam board layer, and an adhesive layer 12 is coated between adjacent skin layers; the adhesive layer 12 has a thickness of 0.3 mm, and the adhesive layer 12 is formed by coating acrylic glue.

[0038] Compared with a single PVC foamed board, the multilayered composite board provided by the present application significantly enhances the nail-holding force of the multilayered composite board by using the superimposed crust layer, so that the multilayered composite board 10 not only has the advantages and disa...

Embodiment 2

[0041] As shown in the figure, the content of this embodiment is basically the same as the structure of Embodiment 1, and the similarities will not be repeated. The difference is:

[0042] PVC crust foam board, including the following components: polyvinyl chloride resin powder 60kg, modified wood wool 30kg, stabilizer 1kg, lubricant 1kg, foaming agent 0.1kg;

[0043] The stabilizer is a composite lead stabilizer; the foaming agent is composed of a yellow foaming agent and a white foaming agent, and the yellow foaming agent is azodicarbonamide, azobisisobutyronitrile, nitroso foaming agent or acyl Hydrazine foaming agent; white foaming agent is sodium bicarbonate, ammonium bicarbonate, ammonium carbonate or azide compound, the mass ratio of yellow foaming agent and white foaming agent is 1:1 ~ 1:4; lubricant is Stearic acid, stearic acid esters, stearic acid alcohol compounds, stearic acid amides, fatty acid metal soaps, polyethylene wax, paraffin wax or oxidized polyethylene....

Embodiment 3

[0054] The content of this embodiment is basically the same as that of Embodiment 2, and the similarities will not be repeated. The difference is:

[0055] PVC crust foam board, including the following components: polyvinyl chloride resin powder 67kg, modified wood wool 35kg, stabilizer 1.5kg, lubricant 1.5kg, foaming agent 1kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com