Feed additive containing proanthocyanidins and dietary fiber, preparation method thereof and non-antibiotic piglet feed product

A feed additive and dietary fiber technology, applied in animal feed, animal feed, food processing, etc., to achieve nutritional balance, improve breeding economic benefits, and improve piglet growth performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

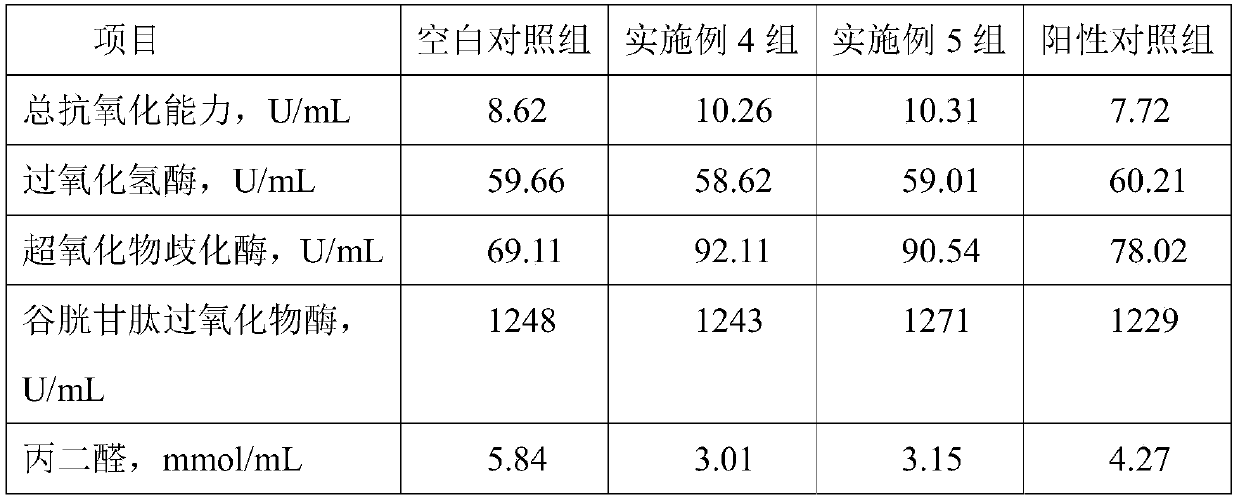

Examples

Embodiment 1

[0025] Example 1 Preparation method of feed additive X1 containing proanthocyanidins and dietary fiber

[0026] Specifically:

[0027] After crushing and sieving, the masson pine bark from Fujian is cleaned and pulverized, and then passed through a 40-mesh sieve. Emulsify and homogenize. Place the crushed and sieved masson pine bark in clean water at room temperature. The material-to-liquid ratio of the crushed masson pine bark to clean water at room temperature is 1g:10mL. Under the condition of a homogenizing pressure of 60MPa, the emulsification is homogeneous After 6 min, the substrate solution is obtained. Ultrasonic-assisted enzymatic hydrolysis, adding a complex enzyme composed of cellulase, pectinase and protease (1:1:1) to the substrate solution after emulsification and homogenization, where the enzyme activity is the enzyme activity of cellulase 0.5U / mg (at 37°C and pH 5.0, the amount of enzyme required to decompose carboxymethyl cellulose to produce 1μmol of glucose in...

Embodiment 2

[0030] Example 2 Preparation method of feed additive X2 containing proanthocyanidins and dietary fiber

[0031] Specifically:

[0032] After crushing and sieving, the masson pine bark produced in Jiangsu is cleaned and pulverized, and then passed through a 60 mesh sieve. Emulsify and homogenize. Put the crushed and sieved masson pine bark in clean water at room temperature. The material-to-liquid ratio of the crushed masson pine bark to clean water at room temperature is 1g:20mL. Under the condition of a homogenizing pressure of 150MPa, the emulsification is homogeneous After 12 minutes, the substrate solution was obtained. Ultrasonic-assisted enzymatic hydrolysis, adding a composite enzyme composed of cellulase, pectinase and protease (1:1:1) to the substrate solution after emulsification and homogenization, and the enzyme activity of cellulase is 1.5U / mg , The enzyme activity of pectinase is 5.0U / mg, and the enzyme activity of protease is 2500U / mg. The ratio of compound enzyme...

Embodiment 3

[0035] Example 3 Preparation method of feed additive X3 containing proanthocyanidins and dietary fiber

[0036] Specifically:

[0037] After crushing and sieving, the bark of Masson pine from Yunnan is cleaned and pulverized, and passed through a 60 mesh sieve. Emulsify and homogenize. Put the crushed and sieved masson pine bark in clean water at room temperature. The material-to-liquid ratio of the crushed masson pine bark to clean water at room temperature is 1g:12mL. Under the condition of a homogenizing pressure of 100MPa, emulsify and homogenize. After 10 minutes, the substrate solution is obtained. Ultrasonic-assisted enzymatic hydrolysis, adding a complex enzyme composed of cellulase, pectinase and protease (1:1:1) to the substrate solution after emulsification and homogenization, and the enzyme activity of cellulase is 1.2U / mg , The enzymatic activity of pectinase is 3.0U / mg, and the enzymatic activity of protease is 2000U / mg. The ratio of the composite enzyme to the sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com