Preparation method of chitosan microspheres and application of chitosan microspheres for removing anionic surfactant

A technology of chitosan microspheres and surfactants, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of low removal efficiency, cost, etc., and is not easy to cause pollution. , broad application prospects, no toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

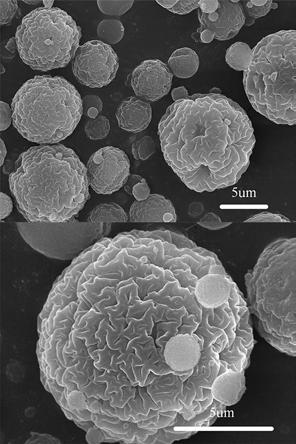

Image

Examples

specific Embodiment approach 1

[0016] 1. The specific embodiment one; the method of a kind of calcium chloride and quaternary ammonium salt modified chitosan microsphere of present embodiment is to carry out according to the following steps:

[0017] 1. Dissolve chitosan and calcium chloride in acetic acid solution, ultrasonically disperse and dissolve evenly in a volumetric flask, and place for a certain period of time to remove air bubbles (as the water phase);

[0018] 2. Pour liquid paraffin into a three-neck round bottom flask, slowly add span80 emulsifier dropwise under electric stirring, and heat in a water bath (as the oil phase); after the solution is evenly stirred, take calcium chloride chitosan solution, and slowly drop into the oil phase , keep the original rotation speed and emulsify to make a W / O type inverse microemulsion; then add glutaraldehyde dropwise, cool to room temperature after cross-linking and solidification, centrifuge the product, discard the upper oil phase, and wash repeatedly...

specific Embodiment approach 2

[0020] 2. Embodiment 2: The difference between this embodiment and Embodiment 1 is that in Step 1, the mass ratio of chitosan and calcium chloride is 1:0.35, and the concentration of the acetic acid solution is 3% (v / v). Others are the same as the first embodiment.

specific Embodiment approach 3

[0021] 3. Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 2, the ratio of span80 to liquid paraffin is 1:20, and the electric stirring speed is 500r / min. Others are the same as those in Embodiment 1 or 2.

[0022] 4. Embodiment 4: The difference between this embodiment and one of Embodiments 1 to 3 is that in step 2, the temperature of the water bath is maintained at 50°C, the ratio of the water phase to the oil phase is 1:10, and the emulsification time is 3h~4h . Others are the same as one of the specific embodiments 1 to 3. Others are the same as one of the specific embodiments 1 to 3.

[0023] 5. Embodiment 5: This embodiment differs from Embodiment 1 to Embodiment 4 in that: in step 2, the ratio of the amount of glutaraldehyde to the water phase is 1:20, and the cross-linking and curing takes 4 hours. Others are the same as one of the specific embodiments 1 to 4.

[0024] 6. Specific embodiment six: what this embodiment is d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com