Preparation method of antimonene nanosheets

A technology of nanosheets and antimonene, which is applied in the coupling of optical waveguides, the manufacture of microstructure devices, and the process for producing decorative surface effects. It can solve the problems of expensive equipment, irregular shapes of nanosheets, and insufficient purity of nanosheets. Advanced problems, to achieve the effect of good thickness uniformity, simple operation and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1. Cut the pure copper foil (purity of 99.999%) into 1cm×1cm size, and place it on the quartz inside the CVD tube furnace;

[0040] Step 2. Filling the CVD tube furnace with Ar gas, then vacuuming with a mechanical pump, repeating 3 times to remove residual oxygen in the quartz tube, etc.;

[0041] Step 3. Set the heating and heating curve, raise the temperature to 1035°C in 52 minutes, and heat and anneal at 1035°C for 60 minutes;

[0042] Step 4. Turn on CVD heating mode and adjust Ar:H 2 The flow ratio is 95:5 (unit: Sccm), and the flow ratio is maintained until the end of annealing;

[0043] Step 5. Weigh 30 mg of pure antimony powder in the glove box, put it into the front end of the CVD tube furnace as the precursor, and place the annealed 1cm×1cm pure copper foil on the end of the quartz tube as a deposition substrate;

[0044] Step 6. Repeat step 2 to vacuum the quartz tube 3 times;

[0045] Step 7. Set the heating curve, raise the temperature to 660°C ...

Embodiment 2

[0050] Similar to Example 1, the difference lies in that the holding time for epitaxial growth in step 7 of Example 1 is regulated to be 5 min.

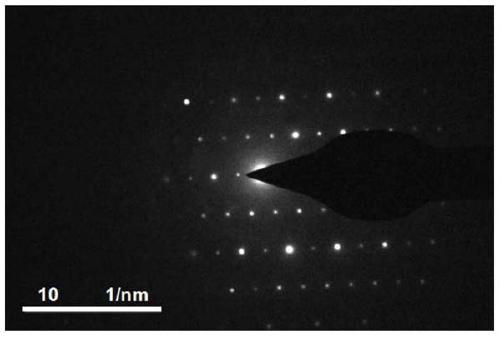

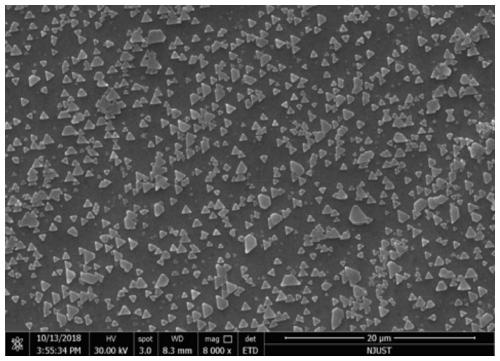

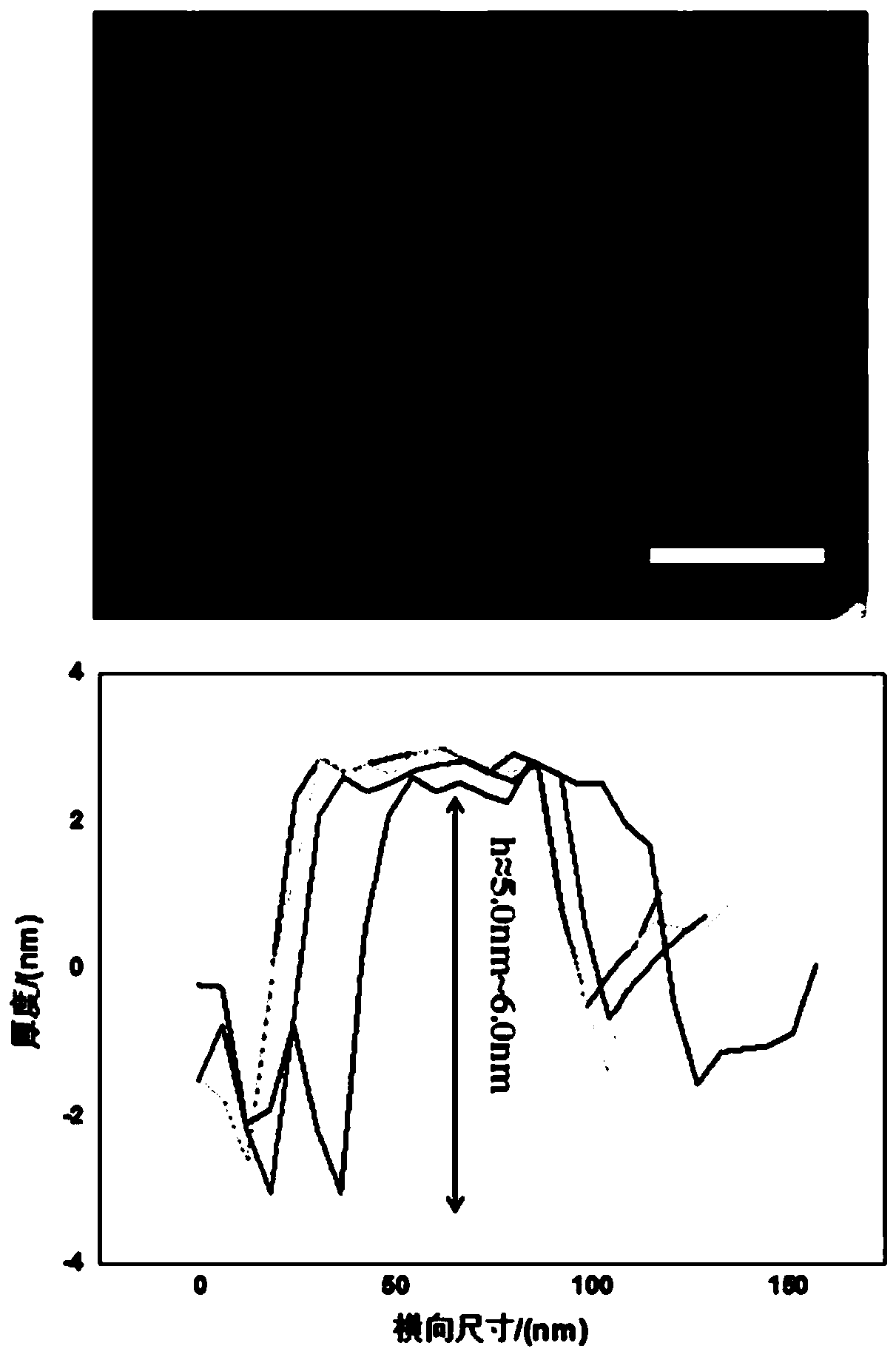

[0051] The SEM images of the triangular or trapezoidal nanosheets prepared in this example are as follows: Figure 4 As can be seen from the figure, the size of the nanosheets is 90 nm to 110 nm in length, the average thickness is about 13 to 16 nm, and the size of the nanosheets is uniform. Raman diagram of antimonene nanosheets Figure 19shown, as can be seen from the picture, at 115cm -1 and 155cm -1 There is a characteristic peak E of few-layer antimonene at g and A 1g , compared to the Raman characteristic peak of bulk antimonene at 110 cm -1 and 150cm -1 , there is obvious blue-shift phenomenon, indicating that the prepared triangular or trapezoidal nanosheets are antimonene substances, with good crystallinity and relatively thin thickness.

Embodiment 3

[0053] Similar to Example 1, the difference lies in that the holding time for epitaxial growth in step 7 of Example 1 is regulated to be 7 min.

[0054] The SEM image of the nanosheets prepared in this example is as follows Figure 5 As can be seen from the figure, the size of the nanosheets is 90-120 nm in length, the average thickness is about 20-25 nm, and the size of the nanosheets is uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com